System and method for treating hydrofluoric acid-containing wastewater

A treatment system and treatment method technology, which is applied in the field of sewage recovery and treatment, can solve the problems of large discharge of hydrofluoric acid-containing wastewater and low recovery rate of hydrofluoric acid, shorten the recovery and treatment cycle, increase the value of renewable utilization, and improve The effect of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

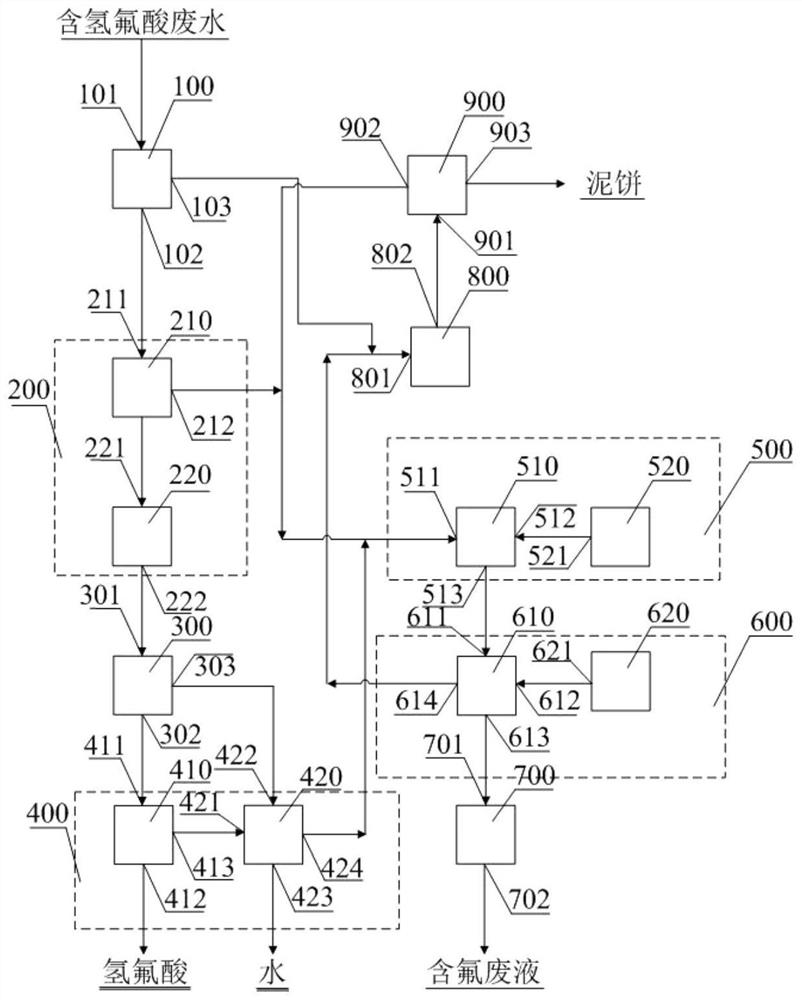

[0059] The daily water output of silicon ingot cleaning wastewater (ie wastewater containing hydrofluoric acid or influent water) in a monocrystalline silicon factory is 200m 3 / d. use as figure 1 The hydrofluoric acid-containing wastewater treatment system shown above treats the above silicon rod cleaning wastewater to obtain fluorine-containing waste liquid (effluent) that meets the discharge standard. The water quality parameters of the above silicon rod cleaning wastewater are shown in Table 1.

[0060] Table 1

[0061] Water Quality Parameters COD(mg / L) SS(mg / L) f - (mg / L)

pH Silicon rod cleaning wastewater (influent) 108 500 3000 0.8

[0062] After the above silicon rod cleaning wastewater is separated through the filter (filter lining material is fluorine-resistant FRP), the effluent SS is reduced to 20mg / L, and hydrofluoric acid and fluorine ions enter the liquid phase, and the remaining fluorine-containing sludge enters the fluorin...

Embodiment 2

[0069] The difference from Example 1 is that the temperature of the heating liquid is 30°C, and the temperature of the enrichment liquid is 15°C.

[0070] See Table 2 for the water quality parameters of fluorine-containing waste liquid (effluent) that meet the discharge standards.

Embodiment 3

[0072] The difference from Example 1 is that the temperature of the heating liquid is 60°C, and the temperature of the enrichment liquid is 5°C.

[0073] See Table 2 for the water quality parameters of fluorine-containing waste liquid (effluent) that meet the discharge standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com