Polycrystalline silicon wastewater treatment method

A technology for wastewater treatment and polysilicon, which is applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., and can solve problems such as high sewage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

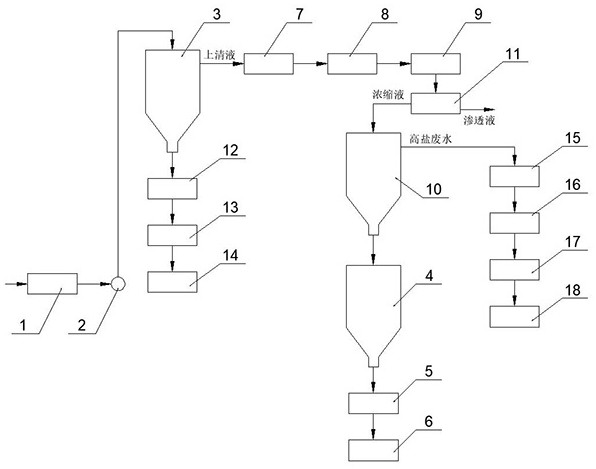

[0037] A kind of polysilicon wastewater treatment method of the present invention, comprises the following steps:

[0038] (1) After adjusting the pH value of the wastewater through the pretreatment tank 1, the polysilicon wastewater is pumped into the primary sedimentation tank 3 through the circulation pump 2 for flocculation and sedimentation treatment;

[0039] In the above steps, milk of lime and ozone are added to the pretreatment tank 1 to adjust the pH value of the polysilicon wastewater to 8-10, thereby improving its biochemical characteristics.

[0040] In the above steps, a coagulant is added to the primary sedimentation tank 3, and the coagulant is polyalumina; after the flocculation and precipitation treatment in the primary sedimentation tank 3, the mixture of silicon powder and silicon carbide settles into the primary sedimentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com