Method for efficiently preparing Maillard intermediate by utilizing spray drying-vacuum drying

A technology of vacuum drying and intermediates, applied in the fields of food chemistry and food additives, can solve the problems of inability to large-scale production, low yield, large technical pollution, etc., and achieve the effects of green, safe, pollution-free yield and high-efficiency preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

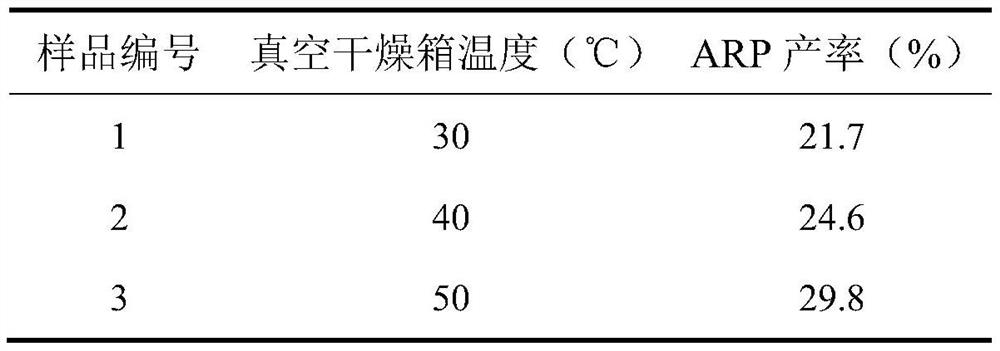

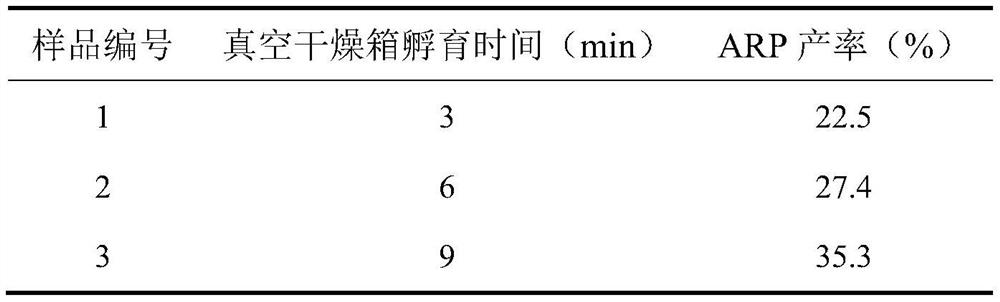

Method used

Image

Examples

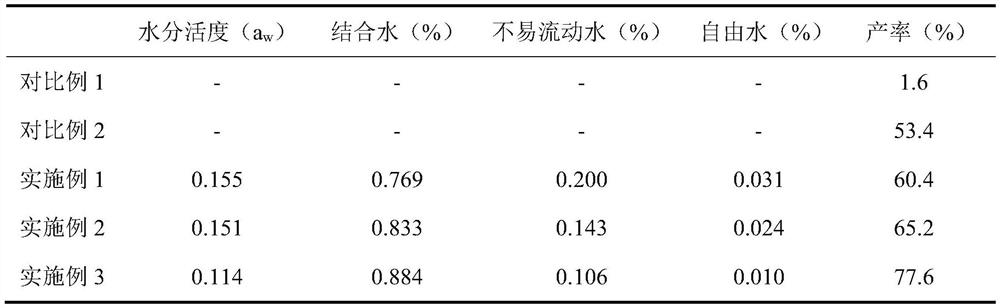

Embodiment 1

[0049] Dissolve 26.6kg of aspartic acid and 60kg of xylose in 1000kg of water, adjust the pH of the mixed solution to 7.5, and react in a water bath at 90°C for 110 minutes to obtain a primary reaction solution. The primary reaction solution was pumped into a concentration tank, and concentrated in a vacuum at 30° C. and a vacuum degree of 40 mbar to a solid content of 18%, to obtain a concentrated reaction solution. Add 40% solid sodium chloride to the obtained concentrated reaction solution, and pump it into a spray drying tower with an air inlet temperature of 160° C. and a flow rate of 15 rpm. After spray drying, Maillard primary powder is obtained. The temperature of the vacuum drying oven was set at 80° C., and the Maillard primary powder was transported to the vacuum drying oven for incubation for 60 minutes to obtain the Maillard reaction intermediate powder. Use high performance liquid chromatography to measure the intermediate yield of aspartic acid-xylose system inc...

Embodiment 2

[0052] Dissolve 26.6kg of aspartic acid and 60kg of xylose in 1000kg of water, adjust the pH of the mixed solution to 7.5, and react in a water bath at 90°C for 110 minutes to obtain a primary reaction solution. The primary reaction solution was pumped into a concentration tank, and concentrated in a vacuum at 30° C. and a vacuum degree of 40 mbar to a solid content of 18%, to obtain a concentrated reaction solution. Add 40% solid sodium chloride to the obtained concentrated reaction solution, and pump it into a spray drying tower with an air inlet temperature of 160° C. and a flow rate of 15 rpm. After spray drying, Maillard primary powder is obtained. The temperature of the vacuum drying oven was set at 90° C., and the Maillard primary powder was transported to the vacuum drying oven for incubation for 20 minutes to obtain the Maillard reaction intermediate powder. Use high performance liquid chromatography to measure the yield of intermediates in the Maillard reaction syste...

Embodiment 3

[0054] Dissolve 26.6kg of aspartic acid and 60kg of xylose in 1000kg of water, adjust the pH of the mixed solution to 7.5, and react in a water bath at 90°C for 110 minutes to obtain a primary reaction solution. The primary reaction solution was pumped into a concentration tank, and concentrated in a vacuum at 30° C. and a vacuum degree of 40 mbar to a solid content of 18%, to obtain a concentrated reaction solution. Add 40% solid sodium chloride to the obtained concentrated reaction solution, and pump it into a spray drying tower with an air inlet temperature of 160° C. and a flow rate of 15 rpm. After spray drying, Maillard primary powder is obtained. The temperature of the vacuum drying oven was set at 90° C., and the Maillard primary powder was transported to the vacuum drying oven for incubation for 40 minutes to obtain the Maillard reaction intermediate powder. Use the low-field nuclear magnetic resonance instrument to measure the existence state of water in the Maillard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com