Ternary composite antibacterial material with photodynamic-photothermal synergistic antibacterial activity as well as preparation method and application thereof

A photothermal synergy, ternary composite technology, applied in the field of antibacterial materials and environmental protection, can solve the problems of limited photocatalytic antibacterial activity, low electron-hole separation efficiency, easy and rapid recombination, etc., to enhance the photocatalytic antibacterial performance. , Improve the photocatalytic antibacterial activity and the effect of wide visible light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

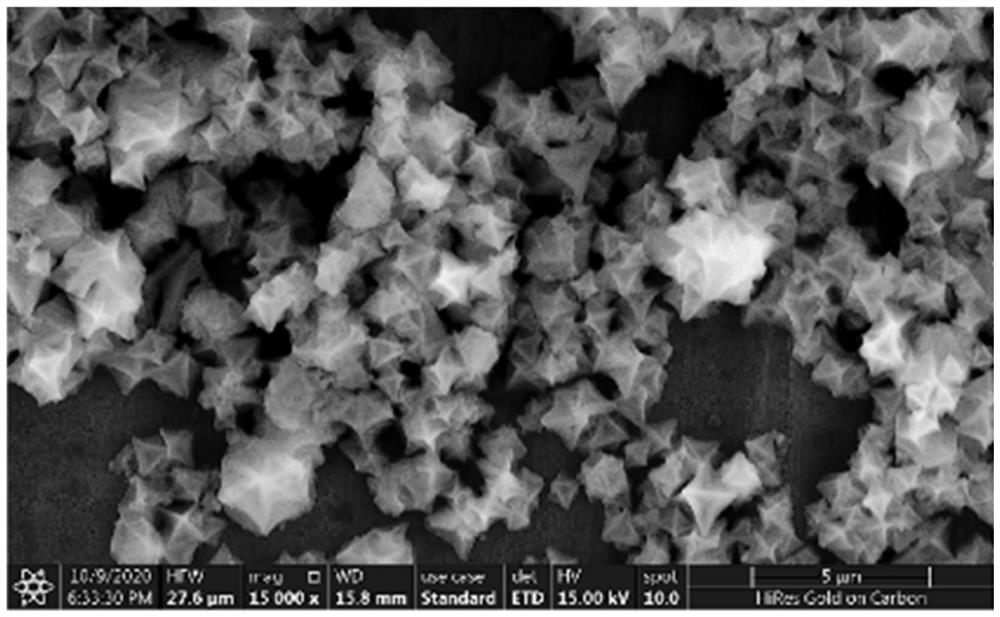

[0040] Step 1, take 4.16mmol FeCl 3 ·6H 2 0 and 2.15mmol 2-aminoterephthalic acid in a beaker, add 50mL solvent DMF and stir until dissolving to obtain the first reaction mixture;

[0041] Step 2. Transfer the first reaction mixture obtained in Step 1 to a polytetrafluoroethylene autoclave (filling ratio 50%), react at 110°C for 24h, and after the reaction is completed, cool to room temperature, centrifuge and wash with water , dried at 50°C for 12 hours, and finally the sample NH 2 -MIL-101(Fe);

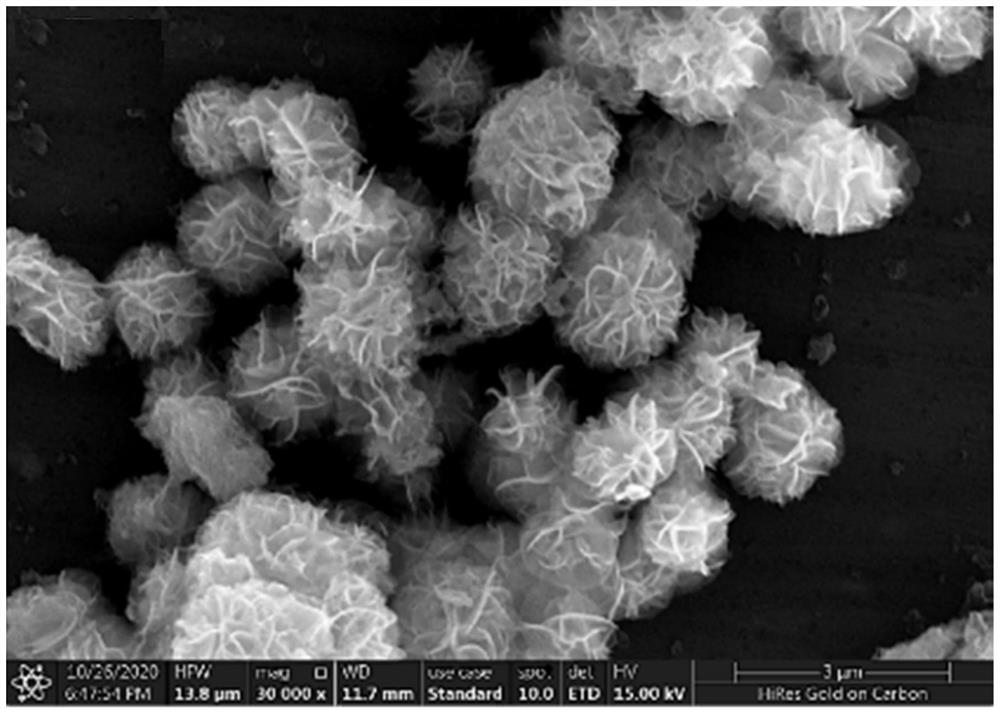

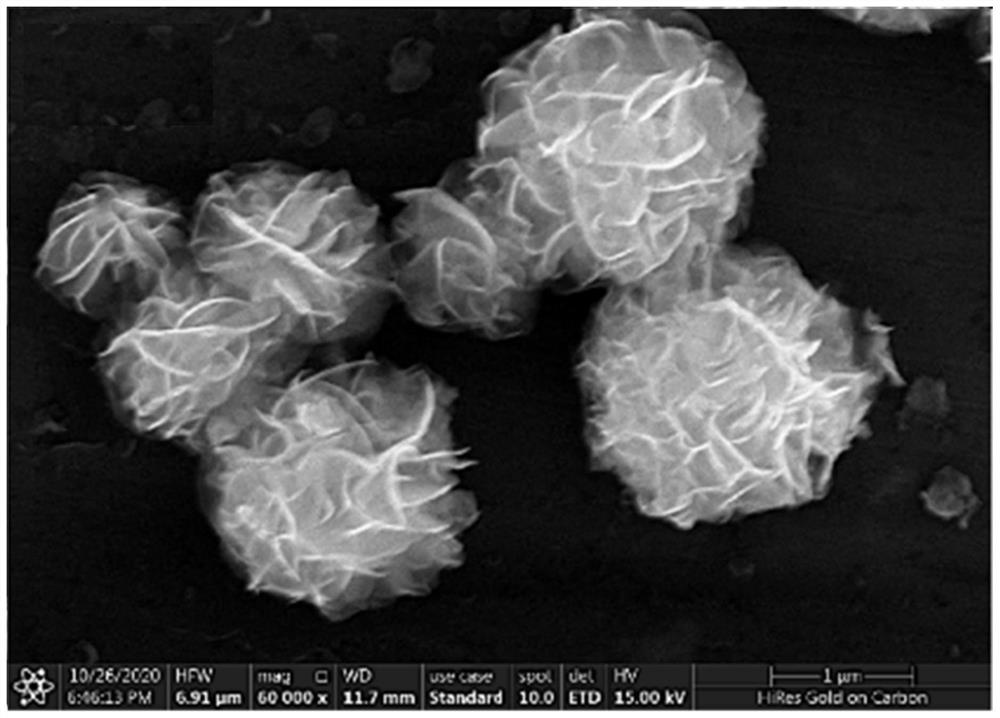

[0042] Step 3: Add 0.3g of sodium molybdate dihydrate and 0.4g of thiourea into 40mL of deionized water, and stir until dissolved to obtain a second reaction mixture;

[0043] Step 4, 0.1g of the sample NH obtained in Step 2 2 -MIL-101(Fe) was dispersed in the second reaction mixture obtained in step 3, stirred evenly and ultrasonically treated for 30 minutes; then, the mixture was transferred to a polytetrafluoroethylene autoclave, and reacted at 180°C for 24 hours. Cool to ro...

Embodiment 2

[0047] Step 1, take 4.16mmol FeCl 3 ·6H 2 0 and 2.05mmol 2-aminoterephthalic acid in a beaker, add 50mL solvent DMF and stir until dissolving to obtain the first reaction mixture;

[0048] Step 2. Transfer the first reaction mixture obtained in step 1 to a polytetrafluoroethylene autoclave (filling ratio 50%), react at 100°C for 20 hours, and after the reaction is completed, cool to room temperature, centrifuge and wash with water , dried at 50°C for 12 hours, and finally the sample NH 2 -MIL-101(Fe);

[0049] Step 3: Add 0.3g of sodium molybdate dihydrate and 0.5g of thiourea into 45mL of deionized water, and stir until dissolved to obtain a second reaction mixture;

[0050] Step 4, 0.1g of the sample NH obtained in Step 2 2 -MIL-101(Fe) was dispersed in the second reaction mixture obtained in step 3, stirred evenly and ultrasonically treated for 30 minutes; then, the mixture was transferred to a polytetrafluoroethylene autoclave, and reacted at 200°C for 20 hours. After ...

Embodiment 3

[0054] Step 1, take 4.16mmol FeCl 3 ·6H 2 0 and 2.47mmol 2-aminoterephthalic acid in a beaker, add 50mL solvent DMF and stir until dissolving to obtain the first reaction mixture;

[0055] Step 2. Transfer the first reaction mixture obtained in step 1 to a polytetrafluoroethylene autoclave (filling ratio 50%), react at 105°C for 22 hours, and after the reaction is completed, cool to room temperature, centrifuge and wash with water , dried at 50°C for 12 hours, and finally the sample NH 2 -MIL-101(Fe);

[0056] Step 3: Add 0.3g of sodium molybdate dihydrate and 0.6g of thiourea into 50mL of deionized water, and stir until dissolved to obtain a second reaction mixture;

[0057] Step 4, 0.1g of the sample NH obtained in Step 2 2 -MIL-101(Fe) was dispersed in the second reaction mixture obtained in step 3, stirred evenly and ultrasonically treated for 30 minutes; then, the mixture was transferred to a polytetrafluoroethylene autoclave, and reacted at 220°C for 25 hours. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com