Lithium ion battery negative electrode composite material and preparation method thereof

A lithium-ion battery and composite material technology, which is applied in the field of lithium-ion battery negative electrode composite materials and its preparation, can solve problems such as restricting the effective application of red phosphorus negative electrodes, high energy consumption by mechanical ball milling, and unfavorable mass production, etc. The effect of electrical conductivity, low cost, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

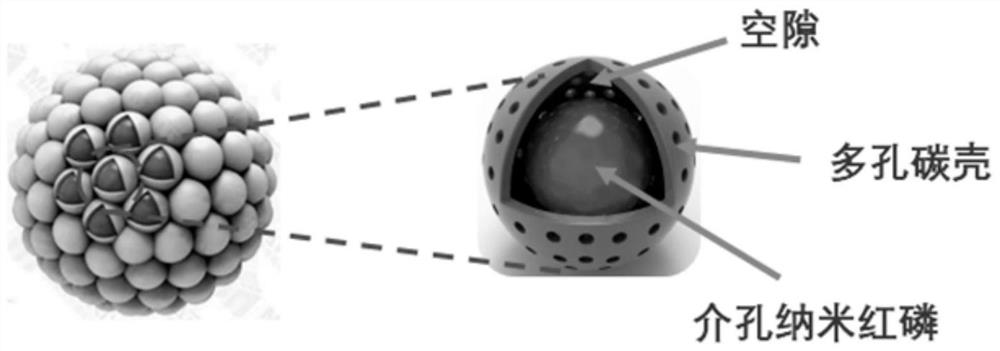

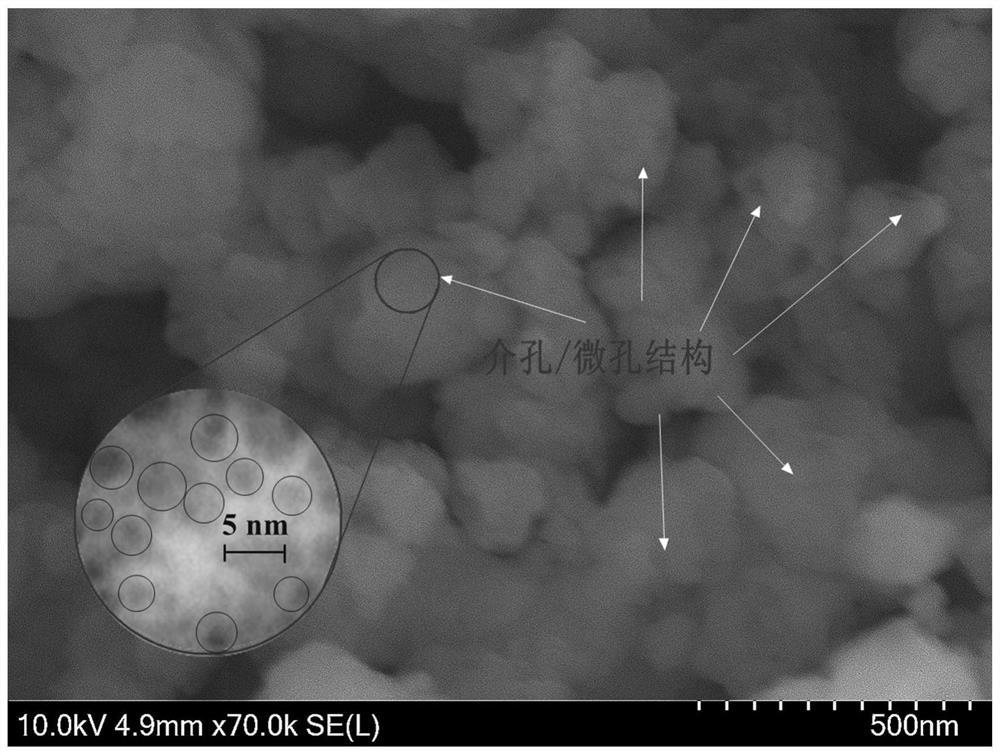

[0026] A porous carbon-coated mesoporous red phosphorus composite material, such as figure 1 As shown, the composite material is composed of multiple spherical nano-scale red phosphorus@carbon primary particles superimposed into micron-scale spherical secondary particles. The nano-scale red phosphorus@carbon primary particle is a carbon layer uniformly coated on the surface of the nano-red phosphorus particle The carbon layer has a porous structure, the nano red phosphorus particles have a mesoporous structure, and there is a gap microstructure between the carbon layer and the nano red phosphorus particles. Its preparation method is as follows:

[0027] Grind 400 mg of micron-sized red phosphorus for 20 minutes, put it into a closed reactor, add 25 mL of propylenediamine and 5 mL of ethylene glycol, and ultrasonicate for 30 minutes; put it in a constant temperature box for 24 hours at 200 ° C, cool to room temperature after the reaction, and let it stand , centrifugation, was...

Embodiment 2

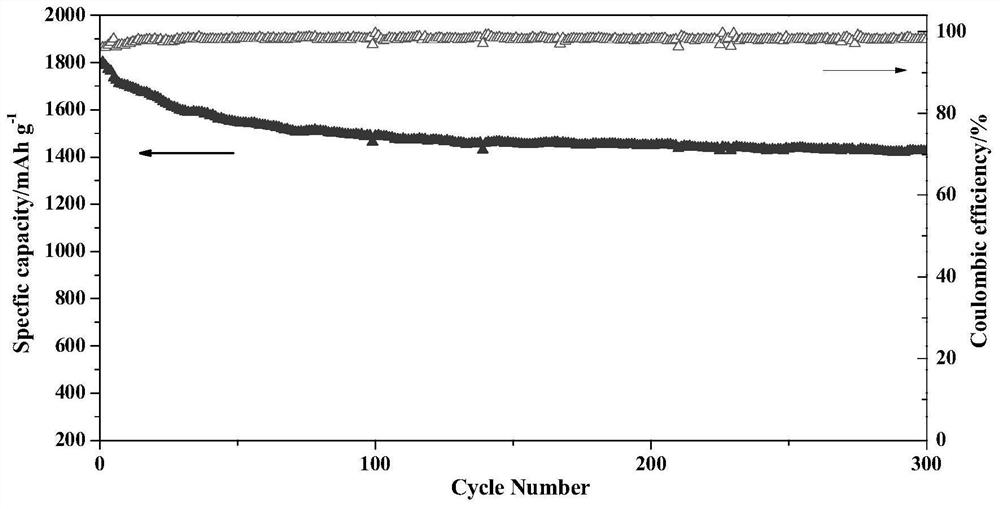

[0030] Same as the above Example 1, the difference is that its preparation method is as follows: take 400mg of micron-sized red phosphorus and grind it for 20min, put it into a closed reactor, add 25mL of butanediamine and 5mL of propylene glycol, and sonicate for 30min; put it in a constant temperature box at 250°C React for 12 hours. After the reaction, cool to normal temperature, let stand, centrifuge, and dry to obtain mesoporous nano red phosphorus particles. Mix 300mg of nano-red phosphorus particles with 250mg of glucose and 2.5mg of nickelocene, and emulsify through high-speed shearing to prepare an emulsion; the emulsion is spray-dried (200°C) to obtain a material precursor; the precursor is placed in a nitrogen-filled The porous carbon-coated mesoporous nano-red phosphorus composite material A2 was obtained by treating in a closed quartz tube at 350°C for 2 hours. The content of red phosphorus in the composite material was determined to be about 75%. The composite ma...

Embodiment 3

[0032] Grind 400mg of micron-sized red phosphorus for 20 minutes, put it into a closed reactor, add 25mL of hexamethylenediamine and 5mL of ethylene glycol, and sonicate for 30 minutes; put it in a thermostat for 36 hours at 150°C, cool to room temperature after the reaction, and let it stand , centrifuging and drying to obtain mesoporous nanometer red phosphorus particles. Mix 300mg of nano-red phosphorus particles with 350mg of polypyrrole and 7mg of ferrocene, and emulsify through high-speed shearing to prepare an emulsion; the emulsion is spray-dried (120°C) to obtain a material precursor; the precursor is placed in a nitrogen-filled The porous carbon-coated mesoporous nano-red phosphorus composite material A3 was obtained by treating in a closed quartz tube at 300°C for 8 hours. The content of red phosphorus in the composite material was determined to be 75%. The composite material was smeared to prepare an electrode, which was assembled with a lithium sheet to form a hal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com