Oxygen carrier coal catalytic pyrolysis hydrogen production reaction device and oxygen carrier coal catalytic pyrolysis hydrogen production method

A reaction device and coal-catalyzed technology, applied in the field of coal-to-hydrogen, can solve the problems of low removal efficiency, failure to reach high-purity level, low hydrogen content, etc., to reduce equipment investment and production costs, good application prospects, and energy utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

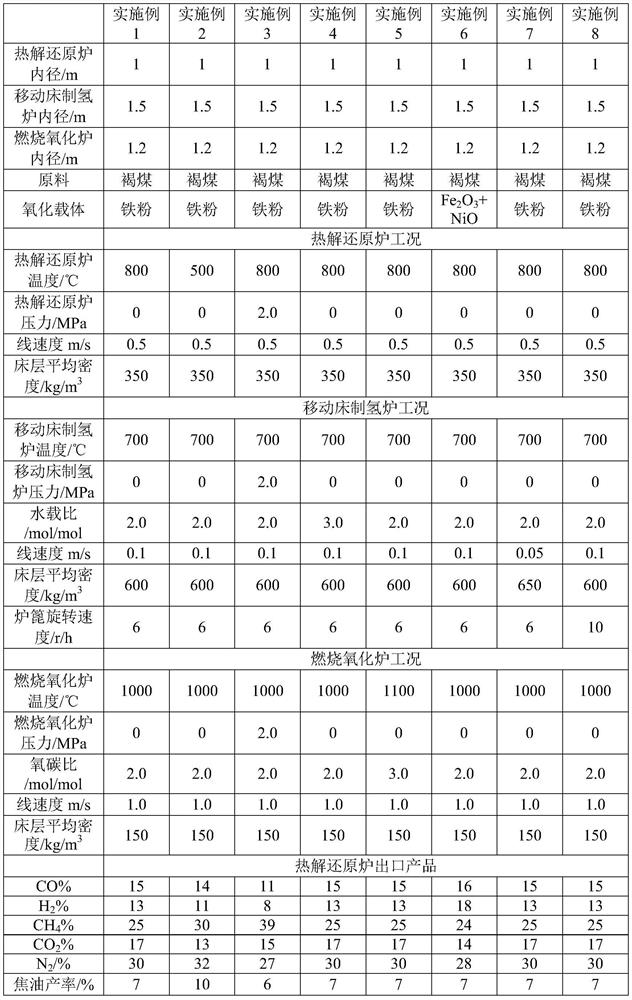

Embodiment 1

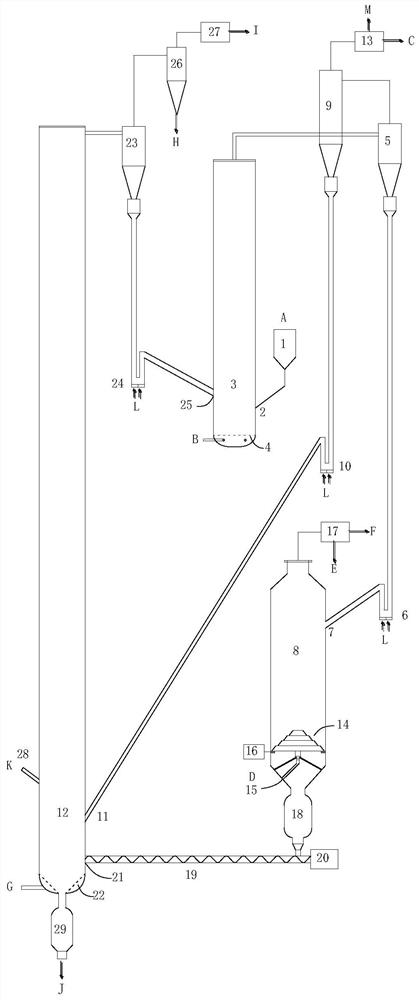

[0074] A new oxygen carrier coal catalytic pyrolysis hydrogen production reaction device, the inner diameter of the lower space of the pyrolysis reduction furnace 3 is 1.0m, the height is 10m, the height of the raw material inlet 2 is located at 3 / 10 of the height of the pyrolysis reduction furnace 3, and the moving bed hydrogen production furnace 8 The inner diameter is 1.5m, and the height is 6m. The combustion oxidation furnace 12 has an inner diameter of 1.2m, and a height of 30m.

[0075] Inner Mongolia lignite is selected as the raw material and fed into the pyrolysis reduction furnace 3 from the raw material inlet 2. The oxidation carrier is iron powder, and the inert agent B nitrogen is introduced into the distributor of the reduction furnace to mix and contact with the oxidation carrier to carry out catalytic pyrolysis and reduction of the oxidation carrier. For the reaction, the pyrolysis reduction furnace 3 operates at a temperature of 800°C and operates at normal pr...

Embodiment 2

[0077] A new oxygen carrier coal catalytic pyrolysis hydrogen production reaction device, the inner diameter of the lower space of the pyrolysis reduction furnace 3 is 1.0m, the height is 10m, the height of the raw material inlet 2 is located at 3 / 10 of the height of the pyrolysis reduction furnace 3, and the moving bed hydrogen production furnace 8 The inner diameter is 1.5m, and the height is 6m. The combustion oxidation furnace 12 has an inner diameter of 1.2m, and a height of 30m.

[0078] Inner Mongolia lignite is selected as the raw material and fed into the pyrolysis reduction furnace 3 from the raw material inlet 2. The oxidation carrier is iron powder, and the inert agent B nitrogen is introduced into the distributor of the reduction furnace to mix and contact with the oxidation carrier to carry out catalytic pyrolysis and reduction of the oxidation carrier. For reaction, the pyrolysis reduction furnace 3 operates at a temperature of 500°C and operates at normal pressu...

Embodiment 3

[0080] A new oxygen carrier coal catalytic pyrolysis hydrogen production reaction device, the inner diameter of the lower space of the pyrolysis reduction furnace 3 is 1.0m, the height is 10m, the height of the raw material inlet 2 is located at 3 / 10 of the height of the pyrolysis reduction furnace 3, and the moving bed hydrogen production furnace 8 The inner diameter is 1.5m, and the height is 6m. The combustion oxidation furnace 12 has an inner diameter of 1.2m, and a height of 30m.

[0081] Inner Mongolia lignite is selected as the raw material and fed into the pyrolysis reduction furnace 3 from the raw material inlet 2. The oxidation carrier is iron powder, and the inert agent B nitrogen is introduced into the distributor of the reduction furnace to mix and contact with the oxidation carrier to carry out catalytic pyrolysis and reduction of the oxidation carrier. For reaction, the pyrolysis reduction furnace 3 operates at a temperature of 800°C and an operating pressure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com