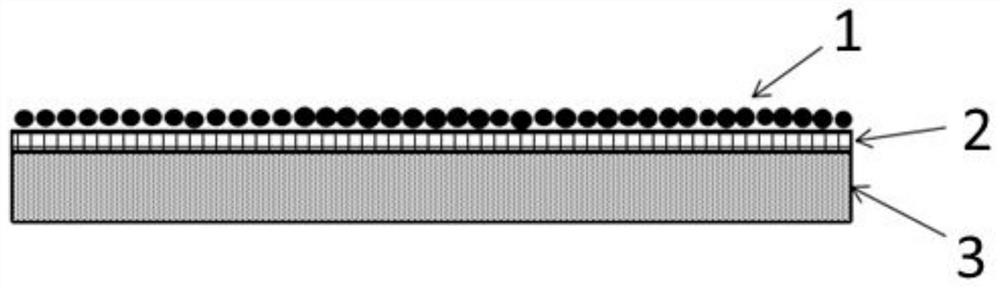

Environment-friendly coating with high corrosion resistance and preparation method thereof

A high-corrosion-resistant, environmentally-friendly coating technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of reduced corrosion resistance, poor closed cells, easy cracking, etc., to improve corrosion resistance, increase surface tension, and firmness enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

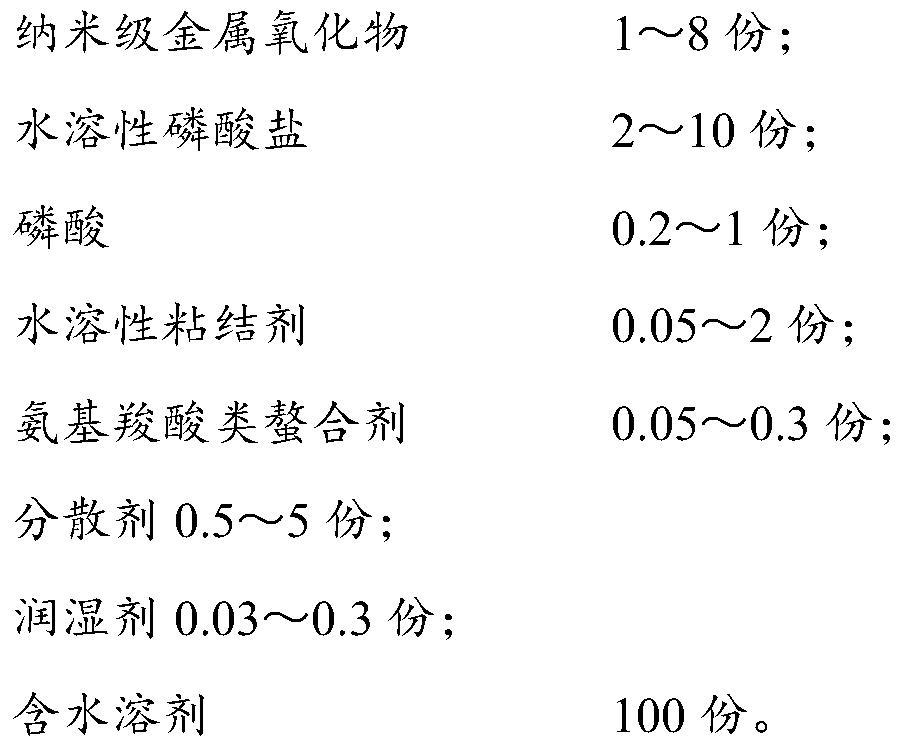

[0056] Inject quantitative pure water into the stirred tank, add 10% methanol in the pure water mass ratio to the pure water to obtain a water-containing methanol solvent, add 2% sodium tripolyphosphate in the solvent mass ratio to the solvent Add the phosphoric acid of 0.2% of the mass ratio of the solvent to the solvent, add sodium hexametaphosphate of 0.5% of the mass of the solvent to the solvent, stir and disperse with the first stirring speed of 100rpm and the first duration of 15min; Nanoscale MnO accounting for 1% by mass of the solvent 2 , stir and disperse with the second stirring speed of 1000rpm and the second duration of 60min; add 0.05% EDTA in the solvent mass ratio to the solvent, and add the nano-scale MnO in the solvent 2 For the acrylic water-based binder with a mass ratio of 5%, add sodium lauryl sulfate accounting for 0.03% of the solvent mass ratio to the solvent, and stir and disperse with the third stirring speed of 100rpm and the third duration of 15mi...

Embodiment 2

[0058] Inject quantitative pure water in the stirred tank, add the methanol that accounts for pure water mass ratio 30% to pure water, obtain the methanol solvent containing water, add the sodium tripolyphosphate that accounts for solvent mass ratio 10% in solvent, to Add 1% phosphoric acid in the solvent mass ratio to the solvent, add 5% sodium lauryl sulfate to the solvent, stir and disperse with the first stirring speed of 300rpm and the first duration of 30min; Add the nanoscale CeO that accounts for solvent mass ratio 8% 2 , stir and disperse with the second stirring speed of 2000rpm and the second duration of 90min; add NTA accounting for 0.3% of the solvent mass ratio in the solvent, and add accounting for nano-scale CeO in the solvent 2 For the polyvinyl alcohol water-based binder with a mass ratio of 20%, add polyoxyethylene alkylphenol ether accounting for 0.3% of the solvent mass ratio to the solvent, and stir and disperse with the third stirring speed of 300rpm and...

Embodiment 3

[0060] Inject quantitative pure water in the stirring tank, add the methanol that accounts for pure water mass ratio 20% to pure water, obtain the methanol solvent containing water, add the sodium tripolyphosphate that accounts for solvent mass ratio 5% in solvent, to Add 0.5% of phosphoric acid in the solvent mass ratio to the solvent, add 3% sodium hexametaphosphate in the solvent mass ratio to the solvent, stir and disperse with the first stirring speed of 200rpm and the first duration of 25min; Nanoscale CeO accounting for 5% by mass of the solvent 2 , stir and disperse with the second stirring speed of 1500rpm and the second duration of 75min; add 0.15% EDTA in the solvent mass ratio to the solvent, and add the nano-scale CeO in the solvent 2 For an acrylic water-based binder with a mass ratio of 12%, add polyether-modified polyorganosiloxane with a mass ratio of 0.15% to the solvent, and stir and disperse at a third stirring speed of 200rpm and a third duration of 25min;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com