Method for rapidly detecting the content of cyanide in white spirit brewing raw materials or distiller's yeast

A technology of cyanide and raw materials, which is applied in the field of liquor analysis and detection, can solve problems such as difficult application of cyanide determination, high requirements for instruments and equipment, difficulty in batching, and simple operation, so as to avoid pre-distillation treatment procedures, low requirements for instruments and equipment, and reduce The effect of matrix interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

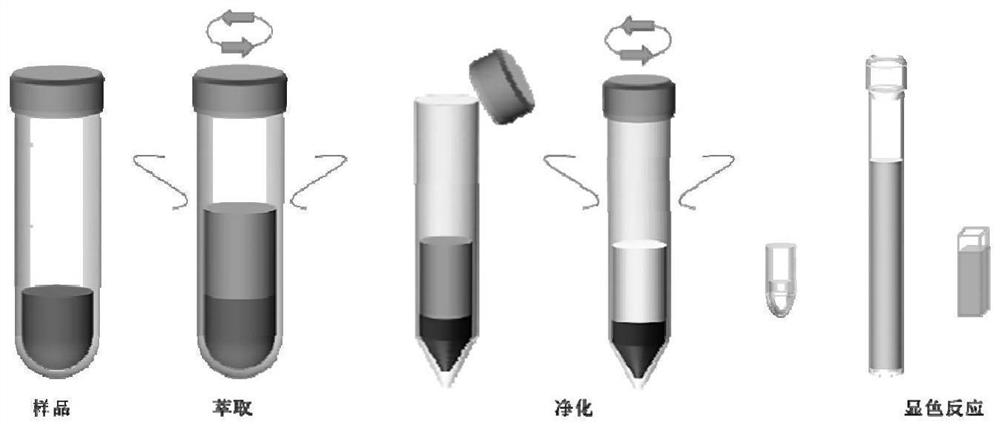

[0066] Embodiment 1 QuEChERS pretreatment of distiller's yeast

[0067] After crushing the koji pieces, pass through a 425μm standard sieve, accurately weigh 5g of koji powder into a 50mL plastic centrifuge tube, add 10mL of water to vortex and mix, soak for 30min, add 15mL of acetonitrile, ultrasonic for 15min, freeze at -20°C for 8min, put a Ceramic homogenizer, add 6.0g MgSO 4 , 1.5g NaOAc, shake and vortex immediately for 1min, then centrifuge at 5000r / min for 5min, draw (8mL) the supernatant until it contains 1200mg MgSO 4 , 400mg C 18 and 400mg GCB in a 15mL plastic centrifuge tube, vortex for 1min, centrifuge at 5000r / min for 5min, pipette 1mL of the supernatant into a 5mL EP tube, blow with nitrogen until nearly dry, add 5mL of 2g / L NaOH for colorimetric and spectroscopic analysis.

Embodiment 2

[0068] Embodiment 2 QuEChERS pretreatment of distiller's yeast

[0069] After crushing the koji pieces, pass through a 425μm standard sieve, accurately weigh 2g of koji powder into a 50mL plastic centrifuge tube, add 4mL of water to vortex and mix, soak for 15min, add 6mL of acetonitrile, sonicate for 8min, freeze at -20°C for 8min, put a Ceramic homogenizer, add 2.4g MgSO 4 , 0.6g NaOAc, shake and vortex immediately for 1min, then centrifuge at 5000r / min for 5min, draw (2mL) the supernatant to contain 300mg MgSO 4 , 100mg C 18 and 100mg GCB in a 15mL plastic centrifuge tube, vortex for 1min, centrifuge at 5000r / min for 5min, pipette 1mL supernatant into a 5mL EP tube, blow with nitrogen until nearly dry, add 5mL 2g / L NaOH for colorimetric and spectroscopic analysis.

Embodiment 3

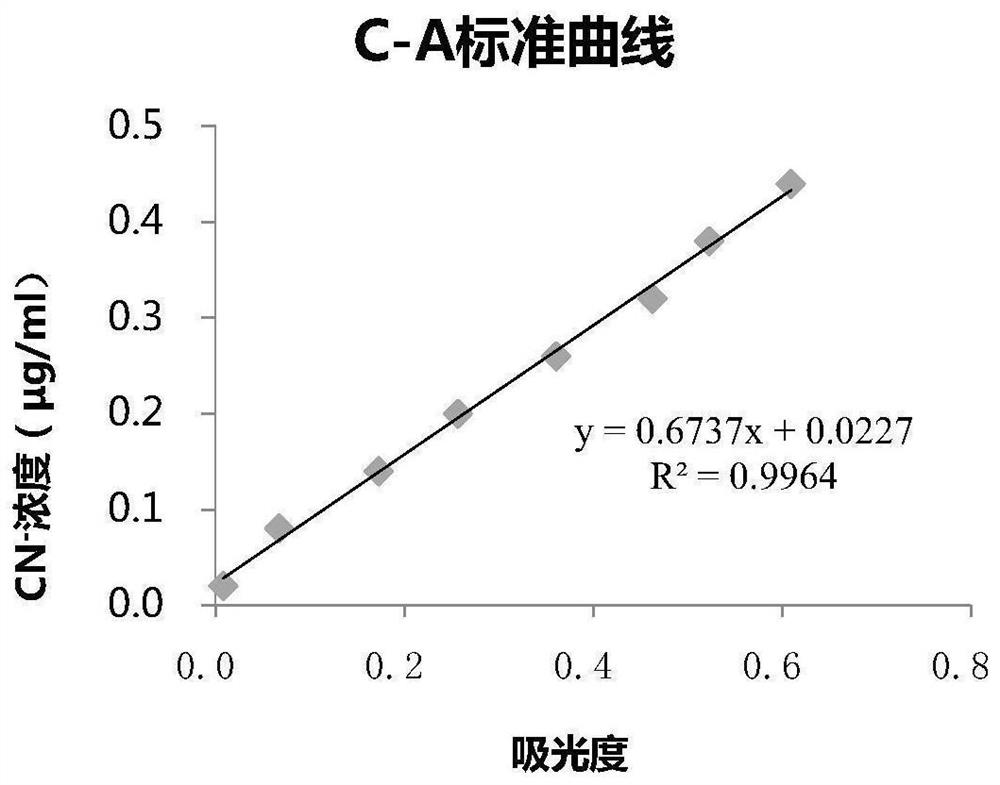

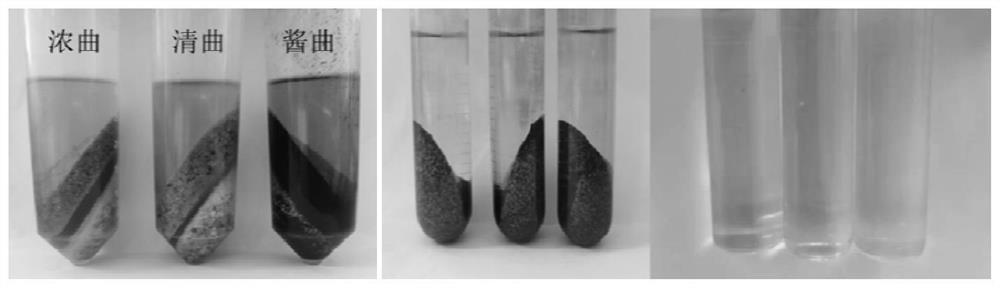

[0070] The mensuration of the cyanide of embodiment 3 liquor brewing koji

[0071] (1) According to the method of Example 1, QuEChERS pretreatment is carried out to Luzhou-flavored distiller's yeast (Nongqu 1), Fen-flavored distiller's yeast (Qingqu 1), and Maotai-flavored distiller's yeast (Jiangqu 1) respectively;

[0072] (2) Color development reaction: Take the samples of Luzhou-flavored koji, Fen-flavored koji, and Maotai-flavored koji treated in step (1) and transfer them to a 10mL stoppered colorimetric tube, add 2 drops of phenolphthalein indicator, and adjust with acetic acid solution. When the red color fades, adjust it to near red with 2g / L sodium hydroxide solution, then add 2mL phosphate buffer solution (if the room temperature is lower than 20°C, put it in a water bath at 25°C-30°C for 10min), then add 0.2mL chloramine T (Preparation) solution, shake well and let stand for 3min, add 2mL isonicotinic acid-barbituric acid solution, add water to the colorimetric tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com