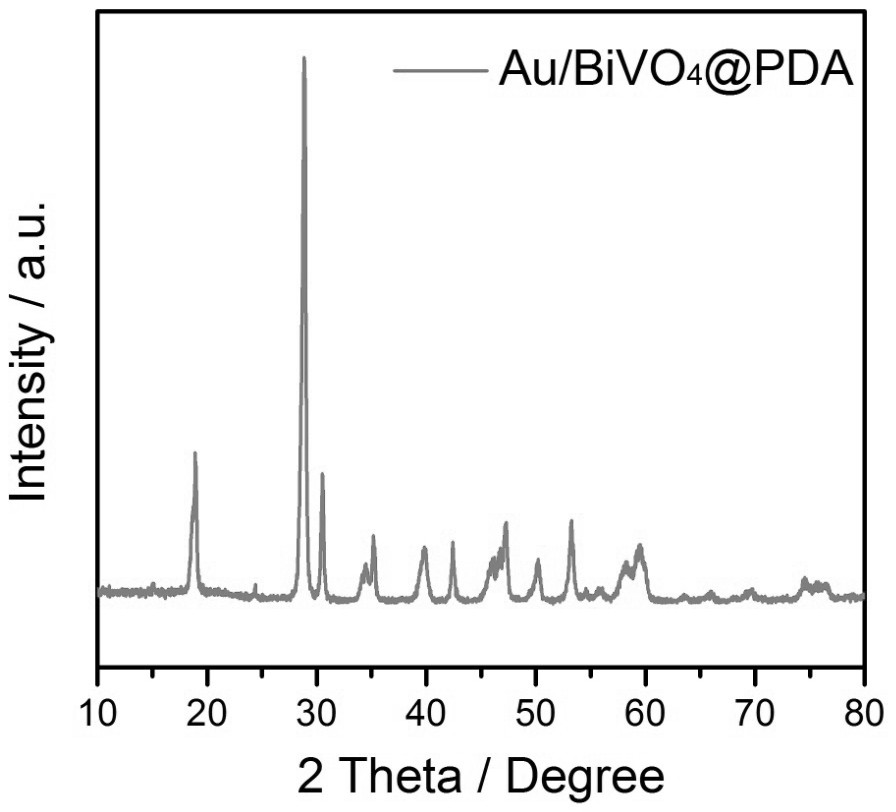

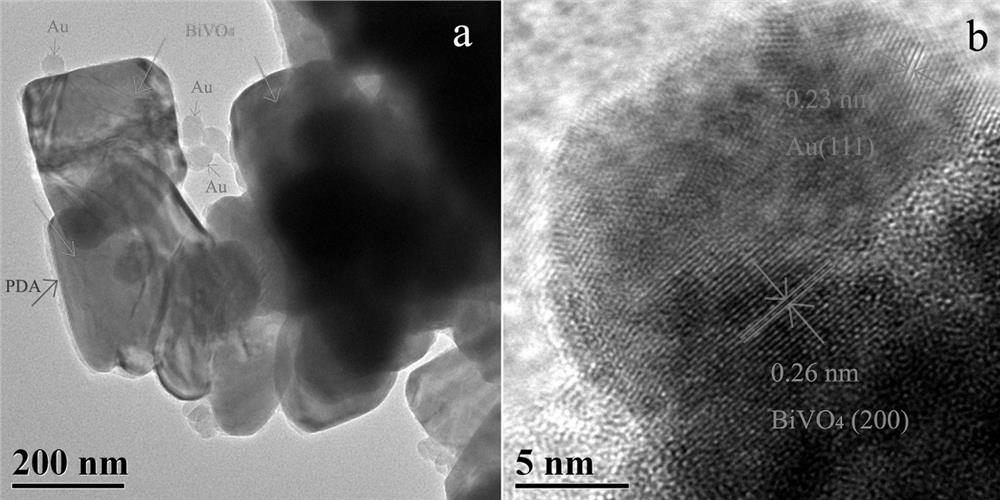

Preparation method of precious metal nanoparticle-loaded 2D bismuth vanadate@PDA core-shell structure composite material

A nanoparticle, core-shell structure technology is applied in the field of organic-inorganic nanocomposite material preparation to achieve the effects of degrading harmful pollutants, being environmentally friendly and simple to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Two-dimensional BiVO 4 The preparation steps of nanosheets are as follows:

[0032] Step a: bismuth salt and sodium dodecylbenzenesulfonate (SDBS) are dissolved in nitric acid solution to obtain solution A according to the molar ratio: bismuth salt: sodium dodecylbenzenesulfonate (SDBS)=1:0.72, Stir for 2h;

[0033] Step b: According to the molar ratio of vanadium-containing compound and bismuth salt: vanadium-containing compound: bismuth salt=1:1, add vanadium-containing compound into NaOH aqueous solution to obtain solution B;

[0034] Step c: Add solution B obtained in step b to solution A obtained in step a, then slowly add an appropriate amount of 2M NaOH aqueous solution, adjust the pH to 6.5, and stir for 2 hours to obtain a uniform suspension;

[0035] Step d: Add the solution obtained in step c into a 50 mL stainless steel reactor lined with polytetrafluoroethylene, keep it at 160 °C for 3 h, separate, wash and dry the obtained product to obtain a two-dimensi...

Embodiment 1

[0043] Two-dimensional BiVO 4 The preparation steps of nanosheets are as follows:

[0044] Step A: Take 1 mmol of Bi(NO 3 ) 3 • 5H 2 O (0.485 g) and 0.72 mmol SDBS (0.250 g) were dissolved in 10 mL of 4M nitric acid to obtain a homogeneous solution;

[0045] Step B: 1 mmol of NH 4 VO 3 (0.117 g) was dissolved in 10 mL of 2M NaOH aqueous solution;

[0046] Step C: Add the solution obtained in step B to the solution obtained in step A, then slowly add an appropriate amount of 2M NaOH aqueous solution, adjust the pH to 6.5, and stir to obtain a uniform suspension;

[0047] Step D: Add the solution obtained in step C into a 50mL stainless steel reaction kettle lined with polytetrafluoroethylene, keep at 160°C for 3h, wash and centrifuge the obtained product alternately with deionized water and absolute ethanol for several times, and then 100°C Drying at lower temperature for 8h, two-dimensional BiVO 4 Nanosheet samples.

[0048] BiVO 4 The preparation steps of @PDA core-...

Embodiment 2

[0055] Two-dimensional BiVO 4 The preparation steps of nanosheets are as follows:

[0056] Step A: Take 1 mmol of Bi(NO 3 ) 3 • 5H 2 O (0.485 g) and 0.72 mmol SDBS (0.250 g) were dissolved in 10 mL of 4M nitric acid to obtain a homogeneous solution;

[0057] Step B: 1 mmol of NH 4 VO 3 (0.117 g) was dissolved in 10 mL of 2M NaOH aqueous solution;

[0058] Step C: Add the solution obtained in step B to the solution obtained in step A, then slowly add an appropriate amount of 2M NaOH aqueous solution, adjust the pH to 6.5, and stir to obtain a uniform suspension;

[0059] Step D: Add the solution obtained in step C into a 50mL stainless steel reaction kettle lined with polytetrafluoroethylene, keep at 160°C for 3h, wash and centrifuge the obtained product alternately with deionized water and absolute ethanol for several times, and then 100°C Drying at lower temperature for 8h, two-dimensional BiVO 4 Nanosheet samples.

[0060] BiVO 4 The preparation steps of @PDA core-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com