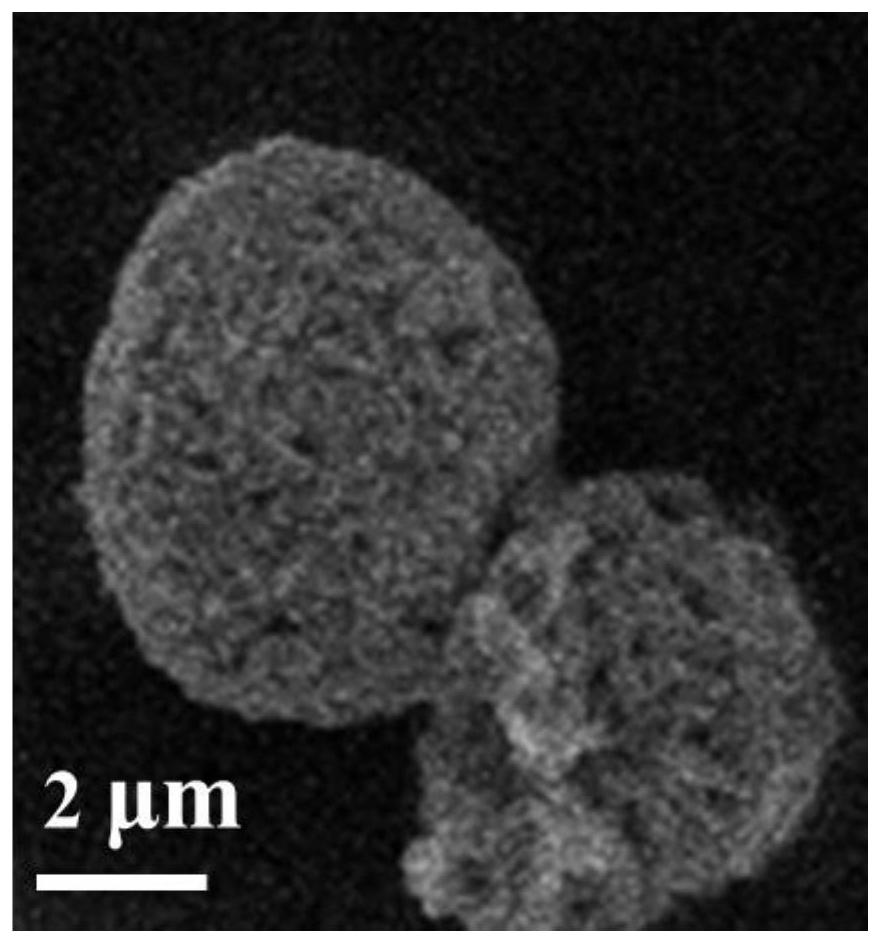

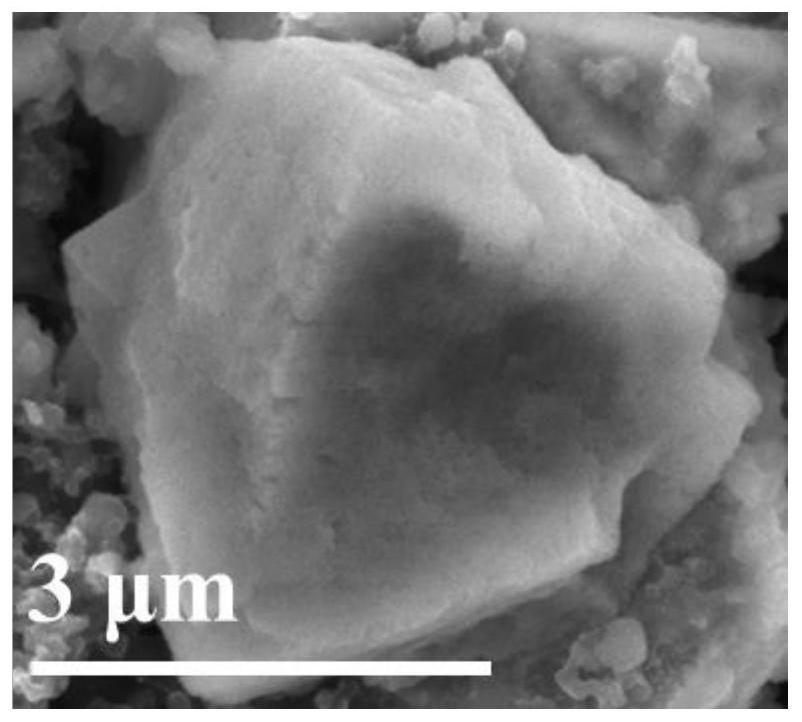

Preparation method of regenerated ternary positive electrode material of lithium nickel cobalt oxide battery

A cathode material, lithium nickel cobalt oxide technology, which is applied in the field of preparation of regenerated ternary cathode materials for nickel cobalt lithium batteries, can solve the problems of poor control of the particle size of the cathode, many side reactions, poor electrochemical performance, etc., and achieve excellent Electrochemical performance, preparation method is simple and easy to operate, and the effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

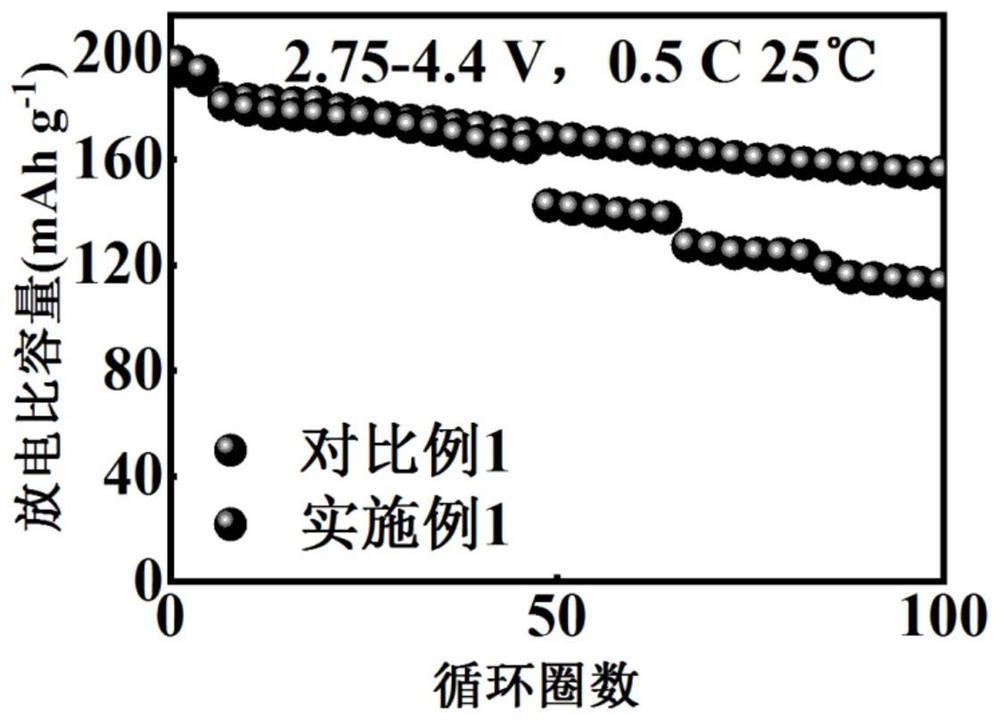

Embodiment 1

[0029] This embodiment includes the following steps:

[0030] (1) Soak and discharge the waste nickel-cobalt lithium battery in 2% sodium chloride solution for 20 hours, then dry and disassemble it, soak it in a sodium hydroxide solution with a concentration of 6mol / L for 1 hour, filter and wash to obtain black powder;

[0031] (2) Take 10 g of black powder (lithium nickel cobaltate active material), put the obtained black powder and iron powder in a mass ratio of 1:1 in a muffle furnace at 800°C for 8 hours;

[0032] (3) Get lithium nickel cobaltate active material 10g, then lithium nickel cobalt acid active material is dissolved in 4mol / L sulfuric acid, control filtrate pH to be 2, add 10L extraction agent, the component of extraction agent is volume fraction is 30% P204 and sulfonated kerosene with a volume fraction of 70%, the equilibration time is 15min, and back extraction with 5L 2mol / L sulfuric acid, the equilibration time is 15min, and the obtained solution is a mixed...

Embodiment 2

[0037] (1) Soak and discharge the waste nickel-cobalt lithium battery in 5% sodium chloride solution for 18 hours, then dry and disassemble it, soak it in a calcium hydroxide solution with a concentration of 8mol / L for 1.5 hours, filter and wash to obtain black powder ;

[0038] (2) Take 20 g of black powder (lithium nickel cobaltate active material), put the obtained black powder and iron powder in a mass ratio of 1:1.5 in a muffle furnace at 800°C for 6 hours;

[0039] (3) Get 20g of the lithium nickel cobalt oxide active material, then dissolve the lithium nickel cobalt oxide active material in 4mol / L nitric acid, control the pH of the filtrate to be 2, add 20L extractant, the component of the extractant is 30% by volume P507 and sulfonated kerosene with a volume fraction of 70%, the equilibration time is 15min, and then back-extracted with 10L 2mol / L sulfuric acid, the equilibration time is 15min, and the obtained solution is a mixed solution of nickel nitrate and cobalt n...

Embodiment 3

[0044] (1) Soak and discharge the waste nickel-cobalt lithium battery in 4% sodium chloride solution for 16 hours, then dry and disassemble it, soak it in an ammonia solution with a concentration of 5mol / L for 1.5 hours, filter and wash to obtain black powder;

[0045] (2) Take 10 g of black powder (lithium nickel cobaltate active material), and place the obtained black powder and sulfur powder in a tube furnace at 900° C. in an argon atmosphere at a mass ratio of 1:1.5 for 8 hours;

[0046] (3) Get lithium nickel cobaltate active material 10g, then lithium nickel cobalt acid active material is dissolved in 4mol / L nitric acid, control filtrate pH to be 2, add 10L extraction agent, the component of extraction agent is volume fraction is 30% P304 and sulfonated kerosene with a volume fraction of 70%, the equilibration time is 15min, and then back-extracted with 5L 2mol / L sulfuric acid, the equilibration time is 15min, and the obtained solution is a mixed solution of nickel nitrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com