Preparation method of oil-resistant and static-conductive anti-corrosive coating added with modified graphene

An anti-corrosion coating and graphene technology, applied in anti-corrosion coatings, conductive coatings, polyether coatings, etc., can solve problems such as bulk accumulation, easy agglomeration, and unbalanced surface charge of nano-graphene powders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

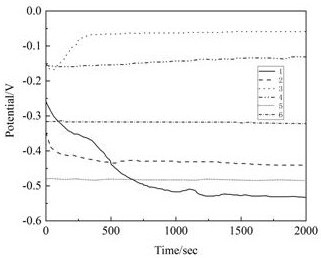

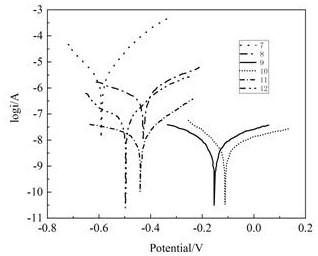

Image

Examples

Embodiment 1

[0026] First, in parts by weight, phenoxy resin 48, trioctyl trimellitate 16, epoxy soybean oil 6, stearyl benzoylmethane 1, OP-10 surfactant 2, phenoxy resin selection GabrielPKHH , Solvent: 73 parts of a mixed solvent of methyl ethyl ketone and glycol ether with a volume ratio of 1:1, the drying temperature of phenoxy resin is 90° C., and the drying time is 24 hours. Extruder, screw diameter, 40mm, gradual compression type, compression ratio, 3:1, speed, 20rpm, aspect ratio, 18:1, number of die holes, 2, furnace wire heating, pressure regulator temperature adjustment, Feeding port, water cooling, the head is equipped with a filter plate and a filter screen, the middle and front of the feed section are at 110°C, 190°C, 220°C, 200°C, and the feed area is water-cooled. The ingredients are weighed separately according to the prescription, and the phenoxy resin and other raw materials are fully stirred. Granulation: Extrude strands and cut into pellets. In the stirred tank equi...

Embodiment 2

[0028] Phenoxy resin slurry and fluorinated graphene oxide are the same as in Example 1. First, preparation of phenoxy resin emulsion: phenoxy resin emulsion is obtained by emulsifying and mixing 9% water-soluble silicone, 0.5% defoamer, 50% phenoxy resin slurry, and the rest is water, and the sum of each component is 100%; The specific emulsification and mixing method is: add water-soluble silicone, antifoaming agent and water into the emulsifier, under stirring, then add the preheated phenoxy resin slurry in a thin line, and fully stir to obtain phenoxy resin Resin emulsion; secondly, preparation of cross-linking solution: in parts by mass, mix 0.2 parts of sodium fluorosilicate, 2 parts of cross-linking agent, 14 parts of modified graphene, and 84 parts of water, heat up to 65°C and stir evenly Disperse for 20 minutes to obtain the cross-linking liquid; then, mixing before the use of the coating: according to the mass ratio, the phenoxy resin emulsion obtained in step 1: cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com