Preparation method of selective emitter of crystalline silicon solar cell

A solar cell and selective technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve problems that are not conducive to increasing short-circuit current, increasing equipment operating costs, and increasing open-circuit voltage, so as to improve photoelectric conversion efficiency and facilitate industrial use , The effect of improving the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

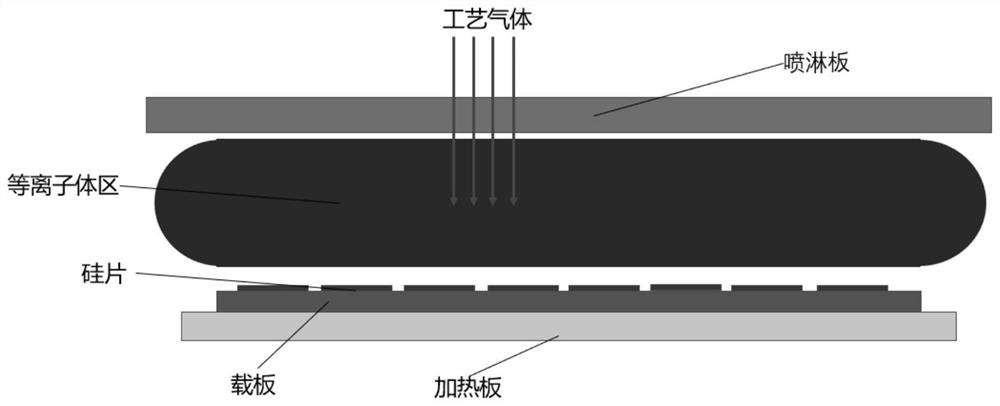

[0032] A method for preparing a selective emitter of a crystalline silicon solar cell. The selective emitter is prepared by borosilicate glass deposition, laser selective localized doping and high-temperature push junction technology, and the PECVD equipment and high-temperature annealing furnace used are Hunan Red Sunlight Technology Co., Ltd. PECVD equipment (such as figure 1 Shown) and high temperature annealing furnace, laser equipment is Wuhan Dier laser equipment, including the following steps:

[0033] (1) Prepare the doping concentration of boron atoms on the surface of the silicon substrate to be 1.3E 21 atoms / cm 3 The borosilicate glass film:

[0034](1.1) Place the carrier plate carrying the silicon substrate (n-type silicon wafer) in the reaction device (PECVD equipment), evacuate it to below 0.05mbar, and heat the reaction chamber (process chamber) until the temperature is 400°C, where the distance between parallel plates in the PECVD equipment (the distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com