Preparation method of high-rate lithium iron phosphate positive electrode material

A cathode material, lithium iron phosphate technology, applied in the field of preparation of high-rate lithium iron phosphate cathode materials, can solve the problems of uneven particles, large material particles, etc., and achieve the effect of good rate performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh first. First weigh 25g of anhydrous ferric phosphate, 6.3g of lithium carbonate, 2.64g of glucose, 0.32g of PEG2000, and 0.25g of titanium dioxide, and disperse the above materials in 5.3g of deionized water, ball mill for 2h, and then transfer to Put into the sand mill, the D50 particle size of the sand mill is controlled at 100-200 nm, so that the iron source, lithium source, carbon source, metal ion dopant and other raw materials are fully mixed evenly, and then centrifugal spray drying is used to obtain a light yellow precursor powder. Put the precursor in a graphite sagger, sinter at high temperature under the protection of nitrogen atmosphere, the sintering cycle is 18-20h, the holding temperature during sintering is 650-700°C, cool naturally, and then pulverize through jet mill, and get high rate after removing iron Lithium iron phosphate cathode material.

Embodiment 2

[0040] Weigh first. First weigh 25g of anhydrous ferric phosphate, 6.3g of lithium carbonate, 3.8g of sucrose, 0.78g of PEG2000, and 0.25g of titanium dioxide, and disperse the above materials in 5.3g of deionized water, ball mill for 2h, and then transfer to Put into the sand mill, the D50 particle size of the sand mill is controlled at 100-200 nm, so that the iron source, lithium source, carbon source, metal ion dopant and other raw materials are fully mixed evenly, and then centrifugal spray drying is used to obtain a light yellow precursor powder. Put the precursor in a graphite sagger, sinter at high temperature under the protection of nitrogen atmosphere, the sintering cycle is 18-20h, the holding temperature during sintering is 650-700°C, cool naturally, and then pulverize through jet mill, and get high rate after removing iron Lithium iron phosphate cathode material.

[0041] Example 2

[0042]Weigh first. First weigh 25g of anhydrous iron phosphate, 6.3g of lithiu...

Embodiment 3

[0044] Weigh first. First weigh 25g of anhydrous iron phosphate, 6.3g of lithium carbonate, 5.68g of glucose, 0.32g of PEG2000, and 0.31g of zirconium dioxide, and disperse the above raw materials in 5.3g of deionized water, ball mill for 2h, and then Turn to sand milling, control the D50 particle size of sand milling at 100-200 nm, fully mix raw materials such as iron source, lithium source, carbon source, metal ion dopant, etc., and then use centrifugal spray drying to obtain light yellow precursor body powder. Put the precursor in a graphite sagger, sinter at high temperature under the protection of nitrogen atmosphere, the sintering cycle is 18-20h, the holding temperature during sintering is 650-700°C, cool naturally, and then pulverize through jet mill, and get high rate after removing iron Lithium iron phosphate cathode material.

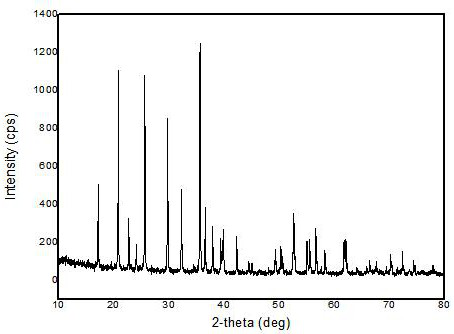

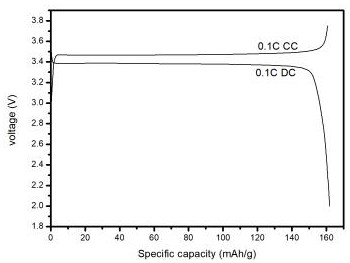

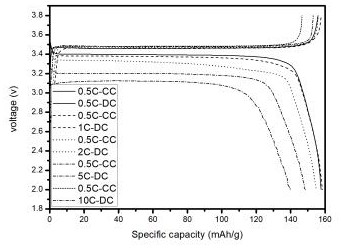

[0045] The lithium iron phosphate material prepared in Example 1 was characterized by a Japanese Rigaku X-ray powder diffractometer (XRD)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com