Grating coupling type Ge series near-infrared waveguide detector and preparation method thereof

A grating coupling and near-infrared technology, which is applied in the fields of semiconductor devices, photovoltaic power generation, and final product manufacturing, can solve the problems of low photodetection efficiency of photodetectors, low detector coupling efficiency, and excessive dark current, and achieve high photoelectricity. Conversion efficiency and photostability, high-response silicon-based integration, solving the effect of low coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with specific embodiments, but the embodiments of the present invention are not limited thereto.

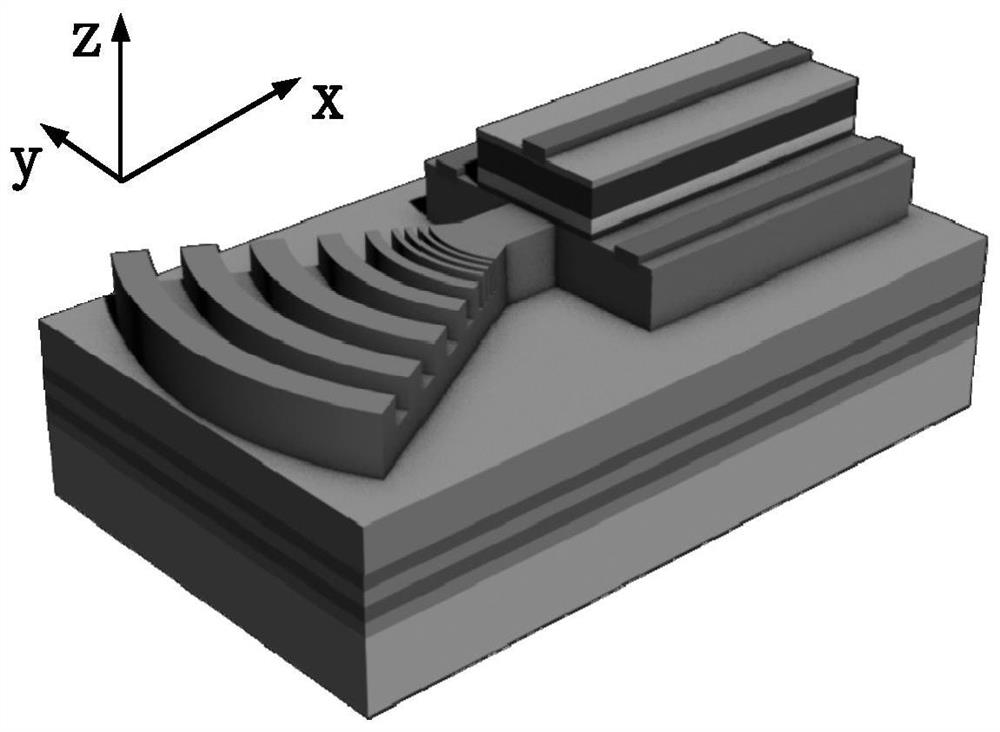

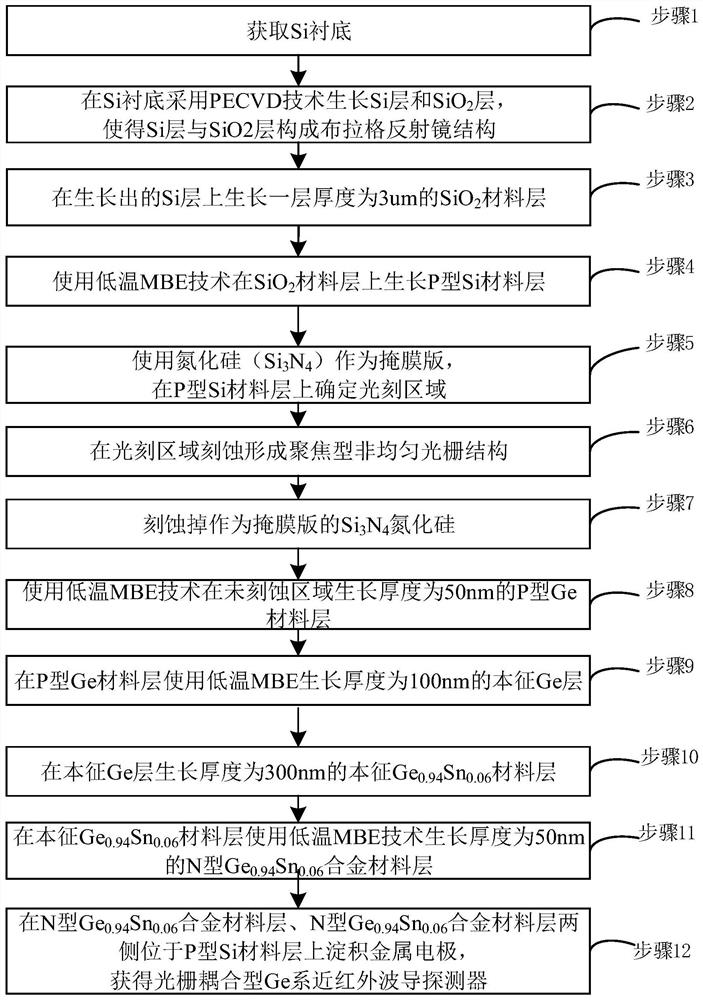

[0052] like figure 1 As shown, a grating-coupled Ge-based near-infrared waveguide detector of the present invention includes:

[0053] The Si substrate, the Si layer and the SiO forming the Bragg mirror structure arranged in order from top to bottom 2 layer, SiO 2 Material layer and P-type Si material layer;

[0054] Focused non-uniform grating structure etched in the etched region on the P-type Si material layer;

[0055] Among them, the focusing non-uniform grating structure is in the shape of a fan ring. In the focusing non-uniform grating structure, the grating is gradually sparse from the inner ring of the fan ring to the outer ring, and the connection between the inner ring of the fan ring and the unetched area presents a cylindrical shape;

[0056] The P-type Ge material layer, the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com