Laser-assisted positive electrode interface layer construction method

A laser-assisted, interface layer technology, applied in the direction of positive electrodes, laser welding equipment, structural parts, etc., can solve the problems of limited thermal stability of pole pieces, unfavorable commercial applications, difficult to apply pole pieces, etc., to avoid interface side effects. Reaction, avoid high temperature heating process, the effect of fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

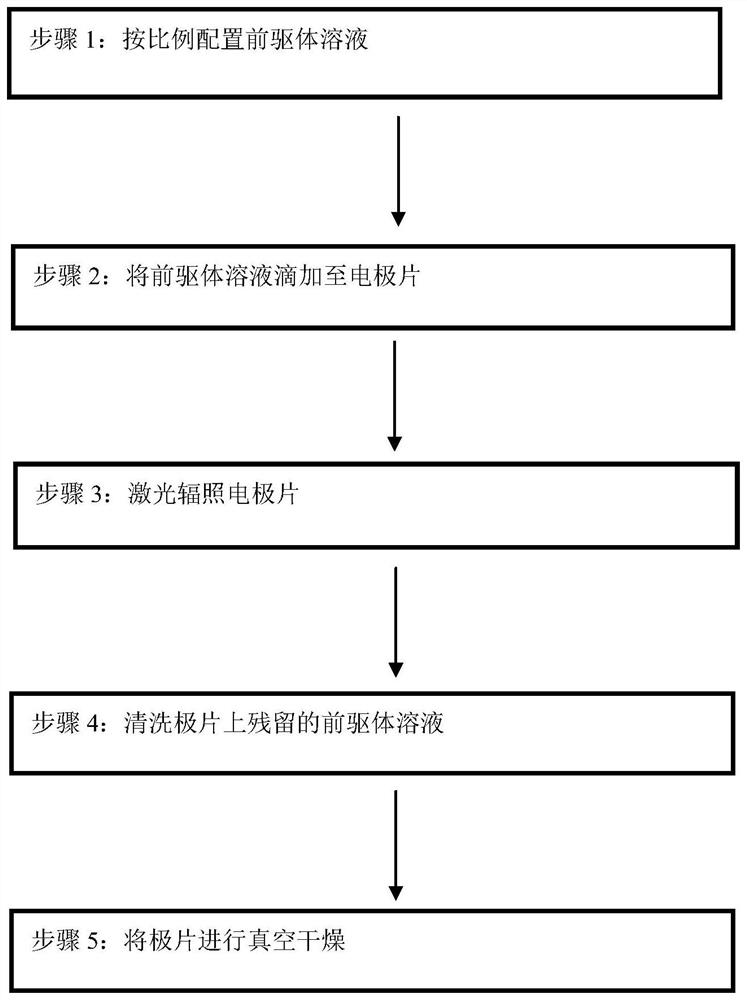

[0036] Step 1, configuring the precursor solution, the volume ratio of tris(trimethylsilane) phosphate to solvent DEC is 10%;

[0037] Step 2. Add 40 μL cm of the precursor solution dropwise to the positive electrode -2 ;

[0038] Step 3. Irradiate the pole piece with pulsed laser, the laser power is 40mJ cm -2 , the frequency is 50HZ, and the irradiation time is 4 minutes;

[0039] Step 4, using diethyl carbonate (DEC) to clean the remaining precursor solution on the pole piece;

[0040] Step 5, vacuum-drying the pole piece obtained in step 4 at 60°C;

[0041] Charge and discharge performance test:

[0042] Put the positive electrode sheet obtained in Example 1 of the present invention in a glove box filled with high-purity argon gas, with water and oxygen concentrations less than 0.1ppm, and use metal lithium sheet as the negative electrode, according to the negative electrode shell, lithium sheet, electrolyte, positive electrode sheet, steel Sheets, shrapnel, and the a...

Embodiment 2

[0047] Step 1, configuring the precursor solution, the volume ratio of tris(trimethylsilane) phosphate to solvent DEC is 20%;

[0048] Step 2. Add 1 mL of precursor solution dropwise to the positive electrode. -2 ;

[0049]Step 3. Irradiate the pole piece with pulsed laser, the laser power is 50mJ cm -2 , the frequency is 60HZ, and the irradiation time is 10 minutes;

[0050] Step 4, using diethyl carbonate (DEC) to clean the remaining precursor solution on the pole piece;

[0051] Step 5, vacuum-drying the pole piece obtained in step 4 at 70°C;

Embodiment 3

[0053] Step 1, configuring the precursor solution, the volume ratio of tris(trimethylsilane) borate to solvent DEC is 2%;

[0054] Step 2. Add 20 μL cm of the precursor solution dropwise to the positive electrode -2 ;

[0055] Step 3. Irradiate the pole piece with pulsed laser, the laser power is 200mJ cm -2 , the frequency is 20HZ, and the irradiation time is 2 minutes;

[0056] Step 4, using diethyl carbonate (DEC) to clean the remaining precursor solution on the pole piece;

[0057] Step 5, vacuum-drying the pole piece obtained in step 4 at 120°C;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com