Surface modification enhanced gypsum powder as well as preparation method and application thereof

A surface modification and gypsum powder technology, which is applied in the field of gypsum powder, can solve the problems of low flexural strength and limit the application of gypsum powder, and achieve excellent comprehensive performance, short initial setting and setting time, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

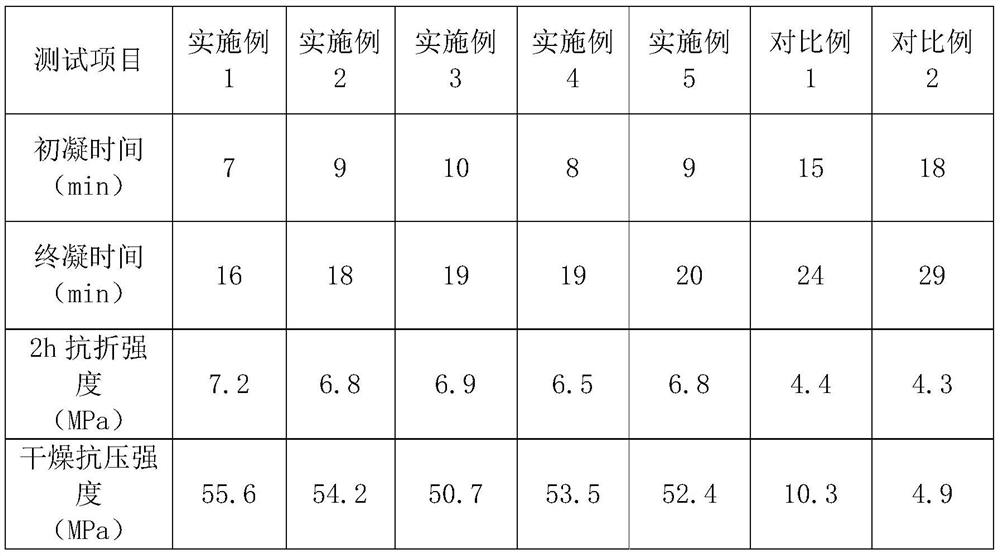

Examples

Embodiment 1

[0022] A surface-modified and enhanced gypsum powder, taking 100kg of α-gypsum as an example, the raw materials used and their quality are as follows:

[0023] α-gypsum 100kg

[0024] Fine sand 35kg

[0025] Redispersible latex powder 2kg

[0026] Cellulose ether 3kg

[0027] Coupling agent 3kg

[0028] Water reducer 0.3kg

[0029] Retarder 0.6kg

[0030] Enhancer 0.5kg;

[0031] In this embodiment, the particle size range of the fine sand is 0.6-0.8 mm; the redispersible latex powder is a copolymer of vinyl acetate and ethylene, prepared by the following method: vinyl acetate and ethylene monomer Under the action of polyvinyl alcohol as a protective glue, the mother emulsion is obtained by emulsion polymerization, and then spray-dried; the cellulose ether is carboxymethyl cellulose ether; the coupling agent is a titanate coupling agent The water-reducing agent adopts polycarboxylate water-reducer, and the water-reducing rate of the polycarboxylate water-reducer is 25%;...

Embodiment 2

[0034] A surface-modified and enhanced gypsum powder, taking 100kg of α-gypsum as an example, the raw materials used and their quality are as follows:

[0035] α-gypsum 100kg

[0036] Fine sand 40kg

[0037] Redispersible latex powder 3kg

[0038] Cellulose ether 1kg

[0039] Coupling agent 2kg

[0040] Water reducer 0.1kg

[0041] Retarder 0.3kg

[0042] Enhancer 0.4kg;

[0043] In this embodiment, the particle size range of the fine sand is 0.6-0.8 mm; the redispersible latex powder is a copolymer of vinyl acetate and ethylene, prepared by the following method: vinyl acetate and ethylene monomer Under the action of polyvinyl alcohol as a protective glue, the mother emulsion is obtained by emulsion polymerization, and then spray-dried; the cellulose ether is ethyl cellulose sulfonate; the coupling agent is titanate coupling agent; the water reducer adopts polycarboxylate water reducer, and the water reducing rate of the polycarboxylate water reducer is 25%; the retarde...

Embodiment 3

[0046] A surface-modified and enhanced gypsum powder, taking 100kg of α-gypsum as an example, the raw materials used and their quality are as follows:

[0047] α-gypsum 100kg

[0048] Fine sand 38kg

[0049] Redispersible latex powder 2kg

[0050] Cellulose ether 2kg

[0051] Coupling agent 4kg

[0052] Water reducer 0.2kg

[0053] Retarder 0.9kg

[0054] Enhancer 0.2kg;

[0055] In this implementation, the particle size range of the fine sand is 0.6-0.8 mm; the redispersible latex powder is a copolymer of vinyl acetate and ethylene, prepared by the following method: vinyl acetate and ethylene monomer Under the action of polyvinyl alcohol as a protective glue, the mother emulsion is obtained by emulsion polymerization, and then spray-dried; the cellulose ether is hydroxypropyl methyl cellulose ether; the coupling agent is titanate coupling agent; the water-reducing agent adopts polycarboxylate water-reducer, and the water-reducing rate of the polycarboxylate water-reducer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com