Chromium-free passivation method for active metal

An active metal, chromium-free passivation technology, applied in the field of metal manganese anti-corrosion, can solve problems such as unsatisfactory passivation effect, excessive sulfur content, unqualified products, etc., to improve passivation effect, reduce sulfur content, reduce The effect of drug dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

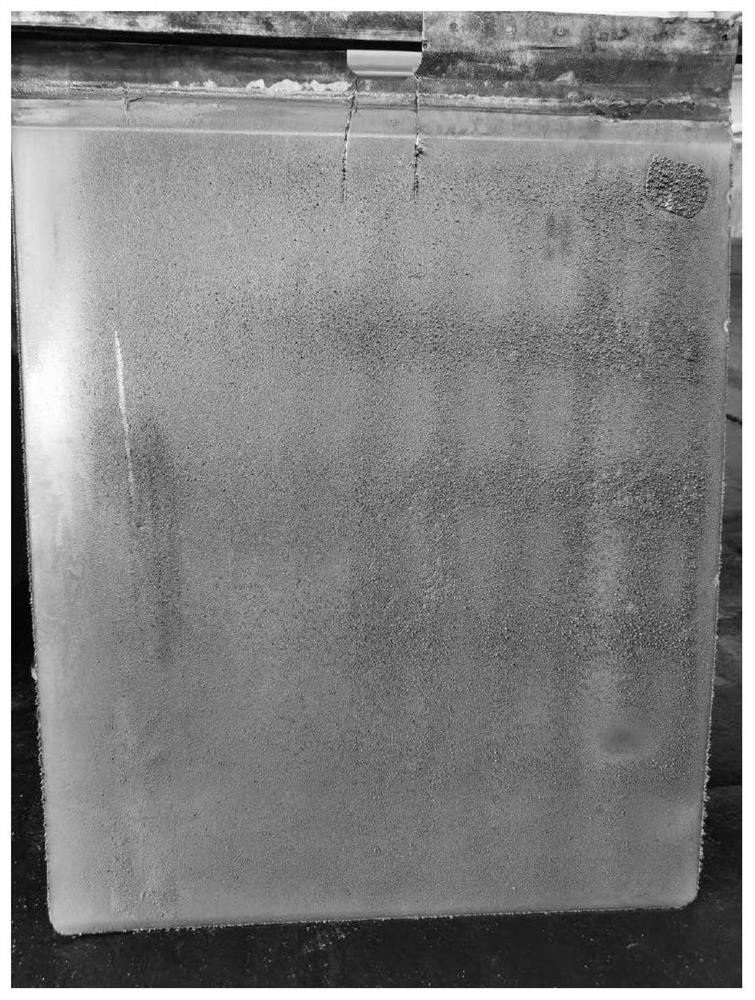

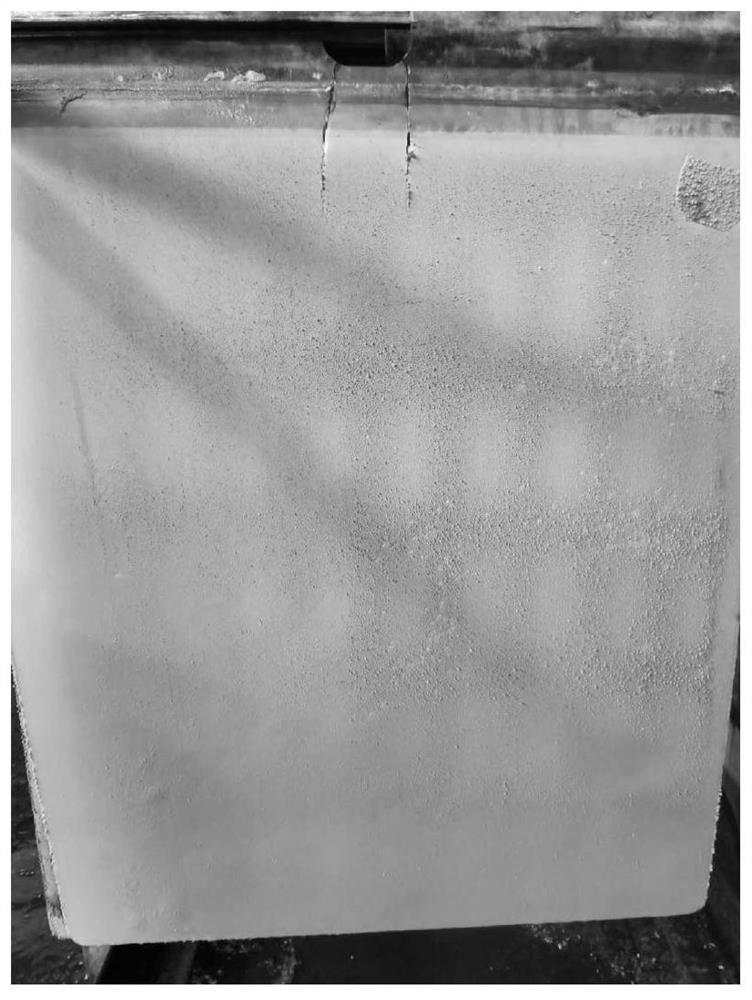

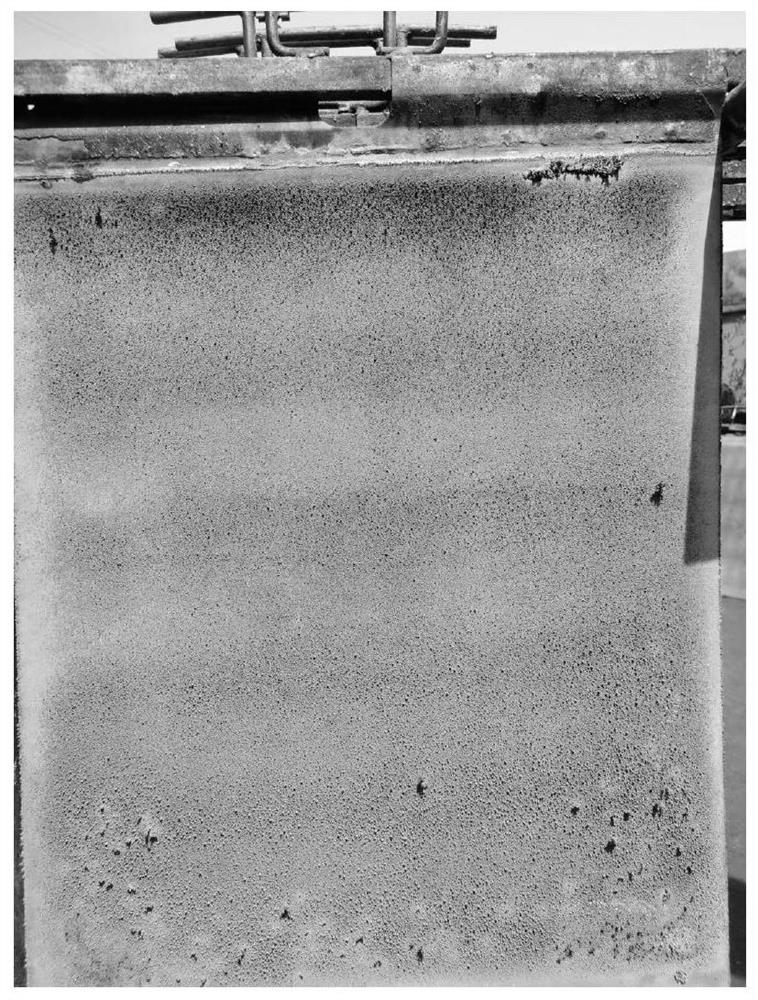

Image

Examples

Embodiment 1

[0054] First, an electrolytic manganese product is prepared in a diaphragm tank by electrolysis: stainless steel is used as a cathode plate, and a lead-silver alloy plate is used as an anode plate. Electrolysis conditions: ammonium sulfate 110g / L, manganese sulfate 76.9g / L, selenium dioxide 0.05g / L catholyte, catholyte pH is about 6.8-7.0, current density is 350A / m2, electrolysis temperature is 38°C, prepared Electrolytic manganese product, the prepared electrolytic manganese product is used for subsequent passivation experiment evaluation.

[0055] The passivation steps are:

[0056] Step (1): first use an aerator to aerate the electrolytic manganese in water for 10 minutes. XPS data shows that the Mn element on the surface of the electrolytic manganese is mainly +2 valence, and the +2 valence accounts for more than 90% of the surface.

[0057] Step (2): Passivation

[0058] Put the aluminum-based chromium-free passivator in the passivation tank, the main component of the a...

Embodiment 2

[0096] The production and preparation conditions of the electrolytic manganese metal product are the same as in Example 1. The passivator used in Example 2 is an aluminum-based chromium-free passivator (same as Example 1), the pH of the passivation solution is 3.5-4.0, and the passivation time is 2.0 min. Continuous production of electrolytic manganese, monitoring of acid consumption during passivation. The test shows that after the electrolytic manganese is produced out of the tank, the electrolytic manganese is first strengthened with an aerator for 10 minutes, then passivated with an aluminum-based chromium-free passivation solution for 2.0 minutes, taken out, and dried to obtain a passivated metal manganese product. According to this technical scheme, for every ton of electrolytic manganese produced, the passivation acid consumption is about 0.18Kg98%H 2 SO 4 . The Mn content of electrolytic manganese products is >99.9%, and the S content is 0.013%. The electrochemical...

Embodiment 3

[0102] The production and preparation conditions of the electrolytic manganese metal product are the same as in Example 1. The passivator used in Example 3 is an aluminum-based chromium-free passivator (same as Example 1), the pH of the passivation solution is 3.5-4.0, and the passivation time is 2.0 min. Continuous production of electrolytic manganese, monitoring of acid consumption during passivation. The test shows that after the electrolytic manganese is produced out of the tank, the electrolytic manganese is first strengthened with an aerator for 3.0 minutes, then passivated with an aluminum-based chromium-free passivation solution for 2.0 minutes, taken out, and dried to obtain passivated metal manganese products . According to this technical scheme, for every ton of electrolytic manganese produced, the passivation acid consumption is about 0.26Kg98%H 2 SO 4 . The Mn content of electrolytic manganese products is >99.9%, and the S content is 0.018%. The electrochemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Self-corrosion current | aaaaa | aaaaa |

| Self-corrosion current | aaaaa | aaaaa |

| Self-corrosion current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap