Preparation method of integrally formed inductor

An inductance and integrated technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of difficult separation of powder, backward powder grading technology, poor precision, etc., to achieve uniform density and ensure surface insulation effect, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing an integrally formed inductor is characterized in that:

[0030] Step 1: Material selection, according to the requirements of the operating frequency (0.1-20MHz), inductance value, power loss, RDC and Isat of the inductance device, select ultra-fine carbonyl iron powder, iron silicon, iron silicon chromium, iron nickel, iron cobalt, etc. The soft magnetic powder is used as the basic powder of the integrated inductor;

[0031] Step 2: Screening, screening soft magnetic powder with a certain particle size distribution through screening mechanism 1 and powder grading technology;

[0032] Step 3: In-situ coating, growing a nano-scale magnetic oxide layer with insulating properties on the surface of the powder through in-situ coating technology;

[0033] Step 4: Coating resin, uniformly coating thermosetting heat-resistant insulating resin on the surface of the powder;

[0034] Step 5: Two-way die floating pressing, preparing an integrally formed ind...

Embodiment 1

[0037] The in-situ insulation coating technology in steps 3 and 4 is as follows: pour the powder into the prepared reaction solution, and stir the powder evenly at a certain temperature; grow a high-insulation soft magnetic oxide film in situ on the surface of the powder , and then the powder is separated, rinsed with a solvent, and then the binder solution is added to the powder, and dried, so that the binder is evenly coated on the surface of the powder.

Embodiment 2

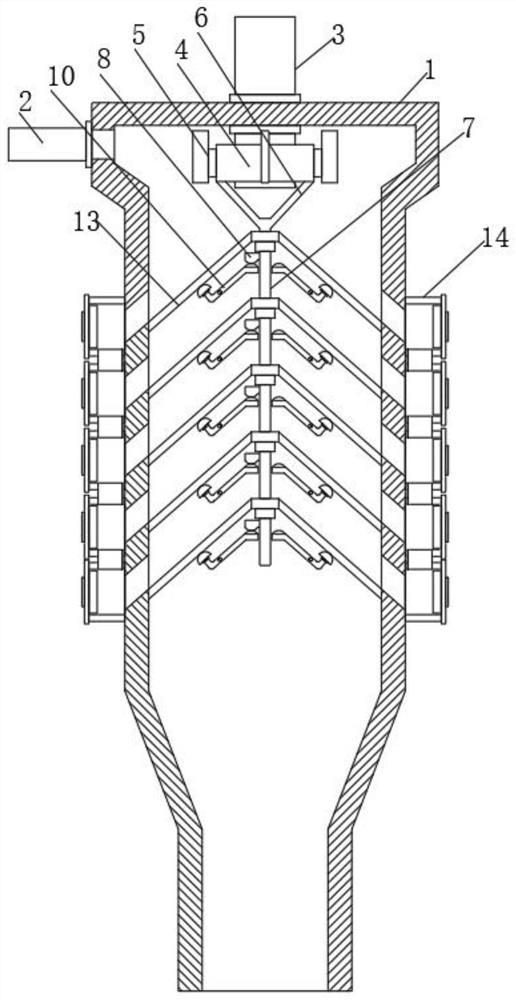

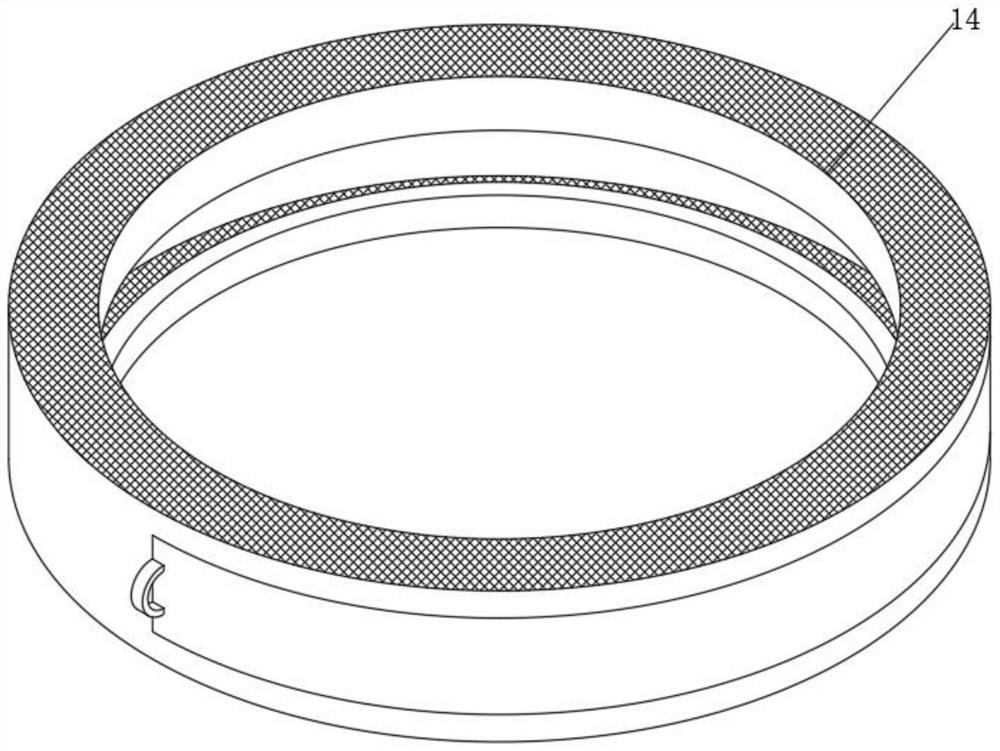

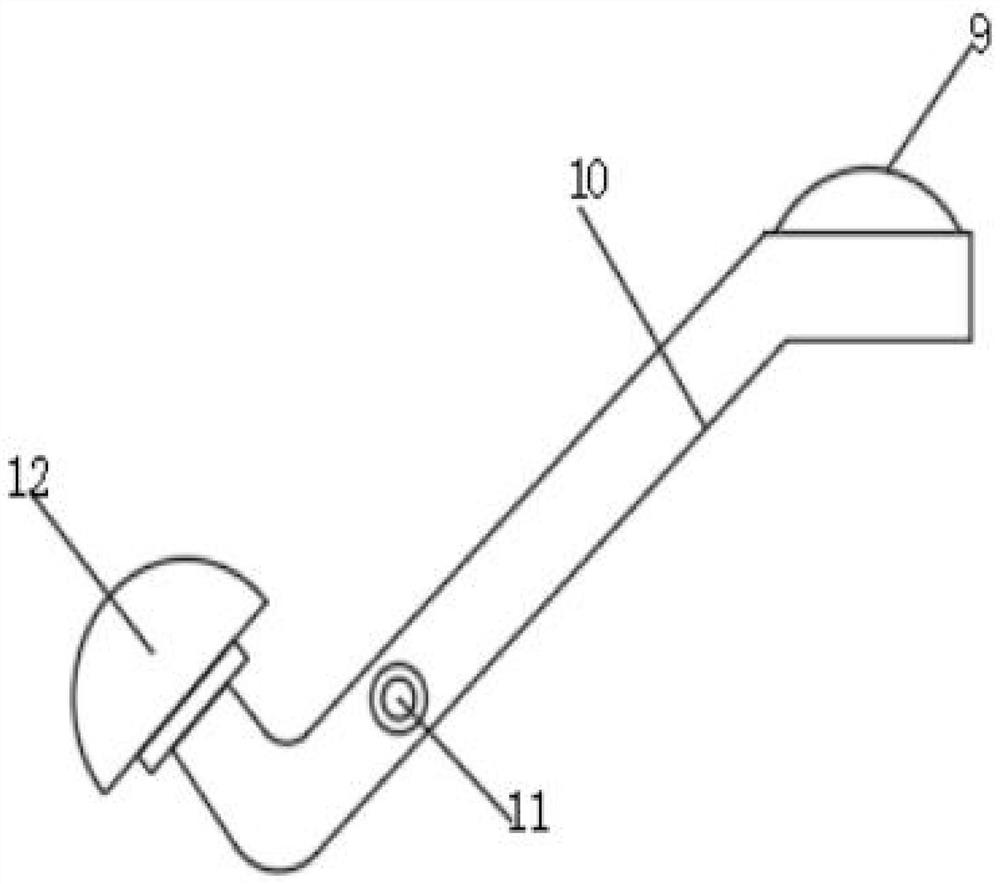

[0039] Please focus on Figure 1-3 , including the screening device 1 in step 2, the input end of the screening mechanism 1 is connected to the feed port 2, the top of the 1 is fixed with the air outlet 3, and the bottom end of the air outlet 3 is provided with a connecting ring 4 with the inside of the screening mechanism 1 The outer wall of the rotating fan blade 5 is fixed, the bottom end of the connecting ring 4 is fixed with a connecting frame 6, the bottom end of the connecting frame 6 is equipped with a rotating rod 7, the outer wall of the rotating rod 7 is fixed with a rotating hammer 8, and the bottom end of the rotating hammer 8 A connecting hammer 9 is connected, the bottom end of the connecting hammer 9 is provided with a connecting rod 10, the inside of the connecting rod 10 is connected with a rotating shaft 11, one end of the rotating shaft 11 is provided with a vibrating hammer 12, and the outer wall of the vibrating hammer 12 is connected with a screen 13 , T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com