Sargassum fusiforme polysaccharide with remarkable anti-photoaging activity and application thereof

A hijiki polysaccharide, anti-photoaging technology, applied in the direction of organic active ingredients, medical preparations containing active ingredients, applications, etc., can solve the problems of unfavorable absorption and utilization, insignificant efficacy, and large molecular weight of polysaccharides, and achieve easy operation , Increase the content of hydroxyproline, increase the effect of total sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

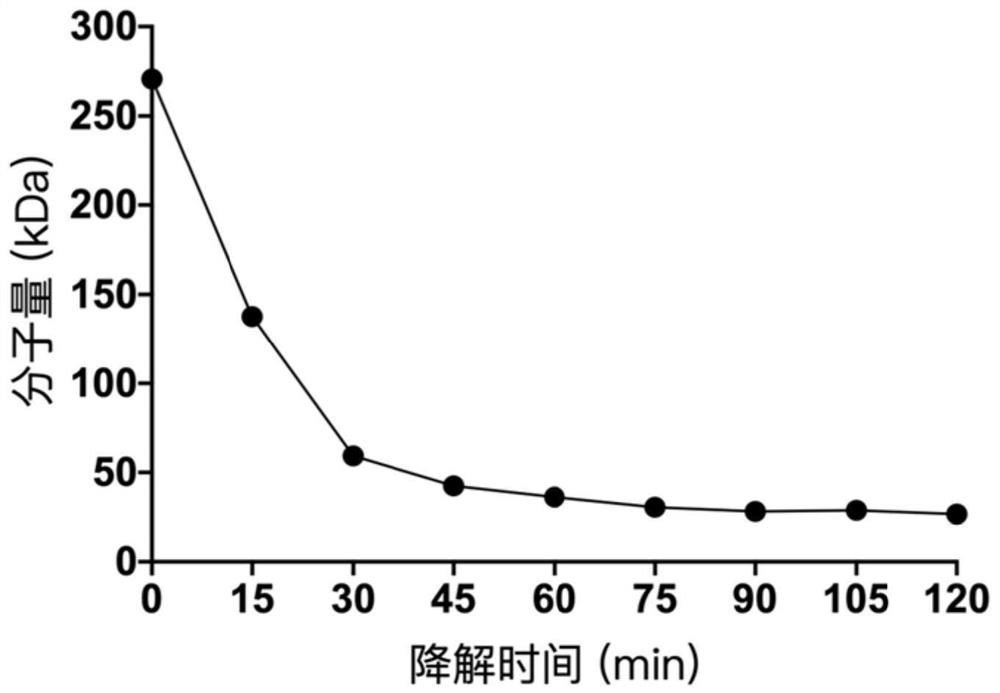

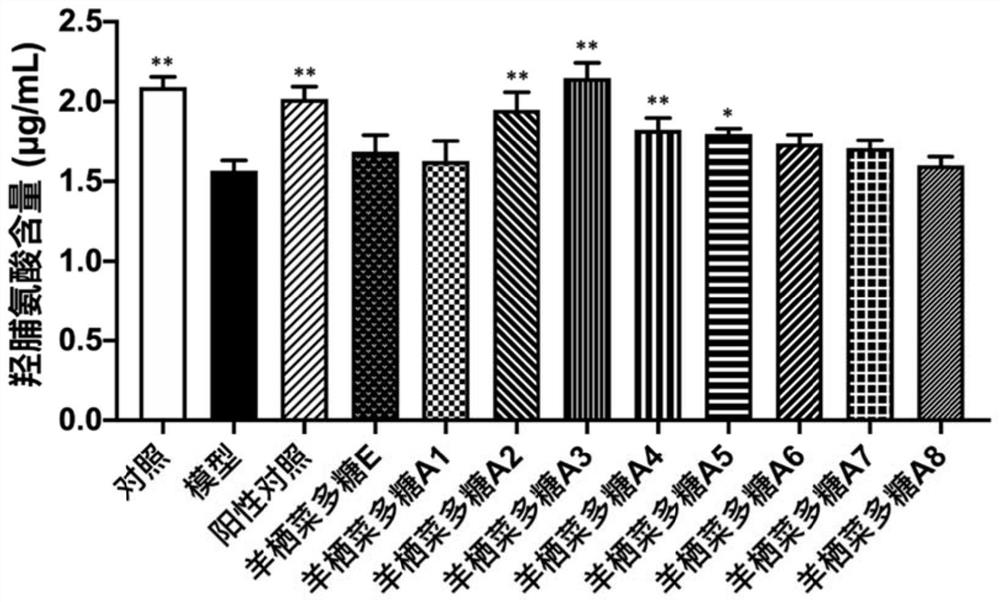

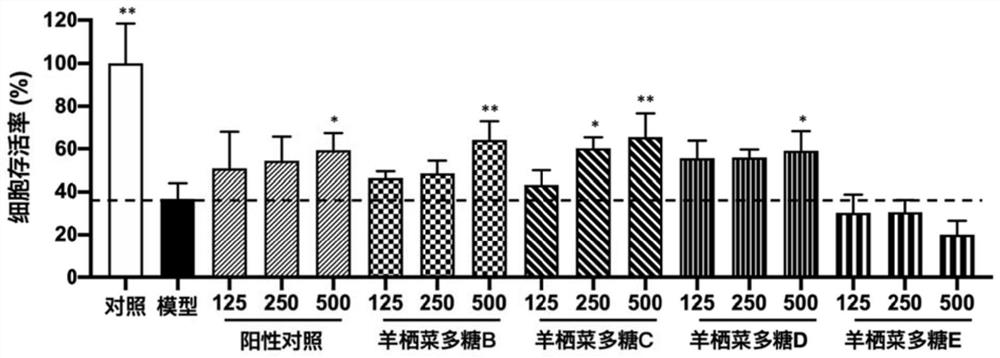

[0031] A hijiki degraded polysaccharide, the preparation method of which is as follows:

[0032] (1) Raw material pretreatment: Use a low-temperature vibrating cell-level ultrafine pulverizer to pulverize the washed and dried hijiki for 10 minutes, set the temperature at -20°C to obtain hijiki superfine powder, and pass through 60 meshes Sieve; weigh 100g of hijiki superfine powder, add 400mL of ethanol with a volume fraction of 95%, reflux three times in a slightly boiling state for a total of 5h, collect the precipitate, and dry to obtain pretreated hijiki powder.

[0033] (2) Extraction of the crude polysaccharide of Hijiki: adding the Hijiki powder into pure water according to the mass volume ratio of 1:50g / mL in step (1) to obtain the Hijiki aqueous solution; The crude polysaccharides of Chickweed, the extraction temperature is 100°C, the extraction time is 4h, the extract is filtered to remove residue, the filtrate is evaporated and concentrated, 95% ethanol is slowly adde...

Embodiment 2

[0036] A hijiki degraded polysaccharide, the preparation method of which is as follows:

[0037] (1) Raw material pretreatment: Use a low-temperature vibrating cell-level ultrafine pulverizer to pulverize the washed and dried hijiki for 5 minutes, set the temperature at -17°C to obtain hijiki superfine powder, and pass through 60 meshes Sieve; weigh 100 g of hijiki superfine powder, add 400 mL of ethanol with a volume fraction of 95%, reflux three times in a slightly boiling state for a total of 4 hours, collect the precipitate, and dry to obtain pretreated hijiki powder.

[0038] (2) Extraction of hijiki crude polysaccharides: adding the hijiki powder into pure water according to the mass volume ratio of 1:40g / mL in step (1) to obtain the hijiki aqueous solution; ultrasonically assisted extraction of hijiki crude polysaccharides For polysaccharides, the hijiki polysaccharide aqueous solution was placed in a cell ultrasonic breaker, ultrasonicated for 40 minutes at a power of ...

Embodiment 3

[0041] A hijiki degraded polysaccharide, the preparation method of which is as follows:

[0042] (1) Raw material pretreatment: Use a low-temperature vibrating cell-level ultrafine pulverizer to pulverize the washed and dried hijiki for 10 minutes, set the temperature at -20°C to obtain hijiki superfine powder, and pass through 60 meshes Sieve; weigh 100g of hijiki superfine powder, add 400mL of ethanol with a volume fraction of 95%, reflux three times in a slightly boiling state for a total of 5h, collect the precipitate, and dry to obtain pretreated hijiki powder.

[0043] (2) Extraction of the crude polysaccharide of Hijiki: adding the Hijiki powder into pure water according to the mass volume ratio of 1:50g / mL in step (1) to obtain the Hijiki aqueous solution; The crude polysaccharides of Chickweed, the extraction temperature is 100°C, the extraction time is 4h, the extract is filtered to remove residue, the filtrate is evaporated and concentrated, 95% ethanol is slowly ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com