Molybdenum disulfide/graphene composite heterojunction and preparation method thereof

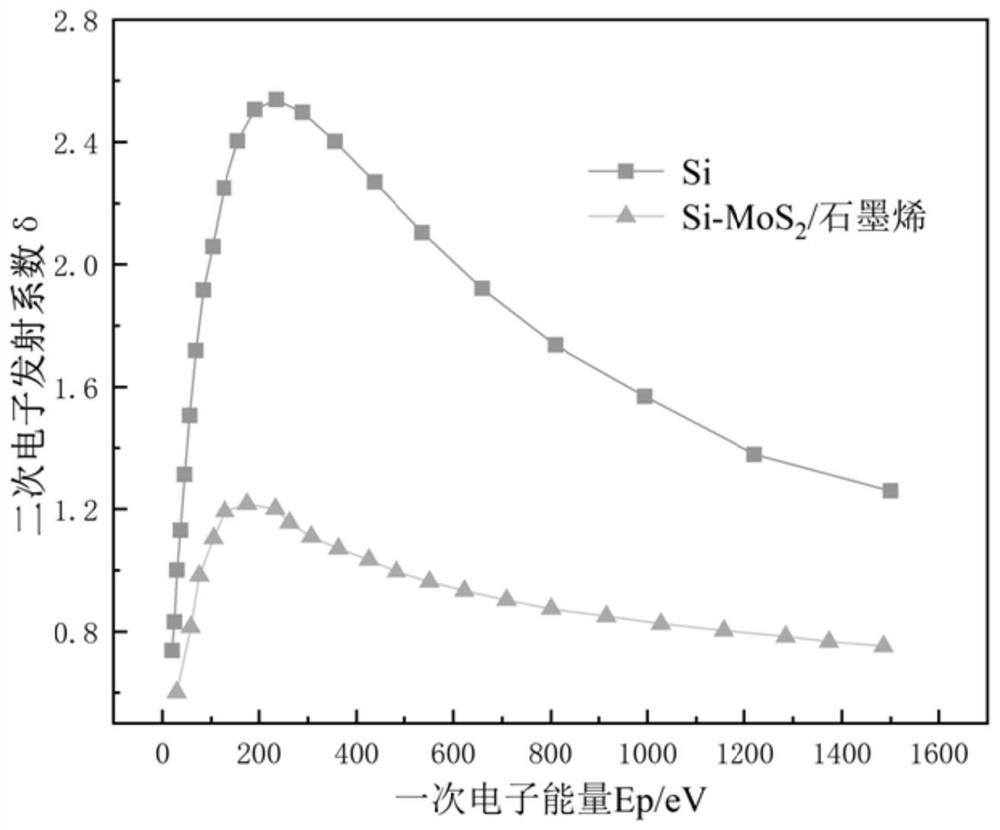

A graphene composite, molybdenum disulfide technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve problems such as poor adhesion, reduce poor stability, improve crystal quality, and reduce costs wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

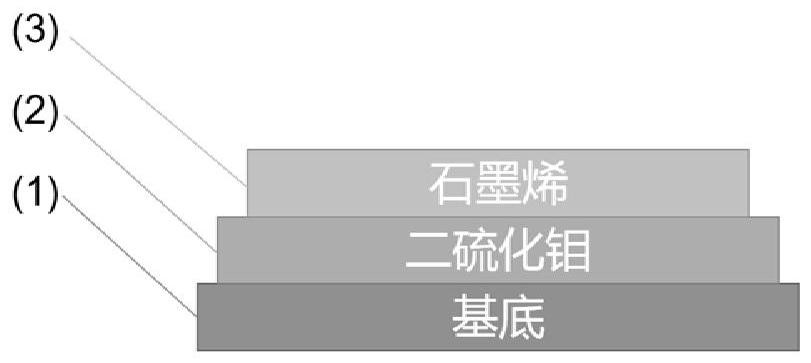

[0034] The object of the present invention is to provide a kind of magnetron sputtering preparation MoS 2 / Graphene composite heterojunction method to suppress micro-discharge effect.

[0035] Step 1: The substrate is ultrasonically cleaned with acetone and alcohol for 20 minutes respectively to remove the adsorption on the surface of the substrate, and blown dry with nitrogen. On the surface of the substrate 1, a molybdenum disulfide buffer layer is deposited on the substrate 1 by means of radio frequency magnetron sputtering molybdenum disulfide target. The working pressure in the cavity is 4Pa, and the thickness of the deposited molybdenum disulfide buffer layer is 10nm;

[0036] Step 2: close the argon gas valve, stop feeding the argon gas with a flow rate of 25 sccm, and feed methane into the coating chamber with a flow rate of 30 sccm, so that the working pressure in the coating chamber is 7Pa, and the thickness of the deposited graphene is 15nm;

[0037] Step 3: Perform...

Embodiment 2

[0039] The object of the present invention is to provide a kind of magnetron sputtering preparation MoS 2 / Graphene composite heterojunction method to suppress micro-discharge effect.

[0040] Step 1: The substrate is ultrasonically cleaned with acetone and alcohol for 20 minutes respectively to remove the adsorption on the surface of the substrate, and blown dry with nitrogen. On the surface of the substrate 1, a molybdenum disulfide buffer layer is deposited on the substrate 1 by radio frequency magnetron sputtering molybdenum disulfide target. The working pressure in the cavity is 10Pa, and the thickness of the deposited molybdenum disulfide buffer layer is 10nm;

[0041] Step 2: close the argon gas valve, stop feeding the argon gas with a flow rate of 30 sccm, and feed methane into the coating chamber with a flow rate of 50 sccm, so that the working pressure in the coating chamber is 10 Pa, and the thickness of the deposited graphene is 15 nm;

[0042] Step 3: Perform hi...

Embodiment 3

[0044] The object of the present invention is to provide a kind of magnetron sputtering preparation MoS 2 / Graphene composite heterojunction method to suppress micro-discharge effect.

[0045] Step 1: The substrate is ultrasonically cleaned with acetone and alcohol for 20 minutes respectively to remove the adsorption on the surface of the substrate, and blown dry with nitrogen. On the surface of the substrate 1, a molybdenum disulfide buffer layer is deposited on the substrate 1 by using radio frequency magnetron sputtering molybdenum disulfide target mode. The working pressure in the cavity is 1Pa, and the thickness of the deposited molybdenum disulfide buffer layer is 10nm;

[0046] Step 2: close the argon gas valve, stop feeding the argon gas with a flow rate of 10 sccm, and feed methane into the coating chamber with a flow rate of 20 sccm, so that the working pressure in the coating chamber is 1Pa, and the thickness of the deposited graphene is 15nm;

[0047] Step 3: Per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com