Method for preparing high-performance polypyrrole/silver selenide/nylon flexible composite thermoelectric thin film

A technology of thermoelectric thin film and silver selenide, which is applied in the manufacture/processing of thermoelectric devices, and the materials of thermoelectric device junction leads, etc., can solve the problems of non-flexibility and limit the application of flexible thermoelectric materials, and achieve the optimization of flexibility and enhancement of phonons Scattering, conductivity enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

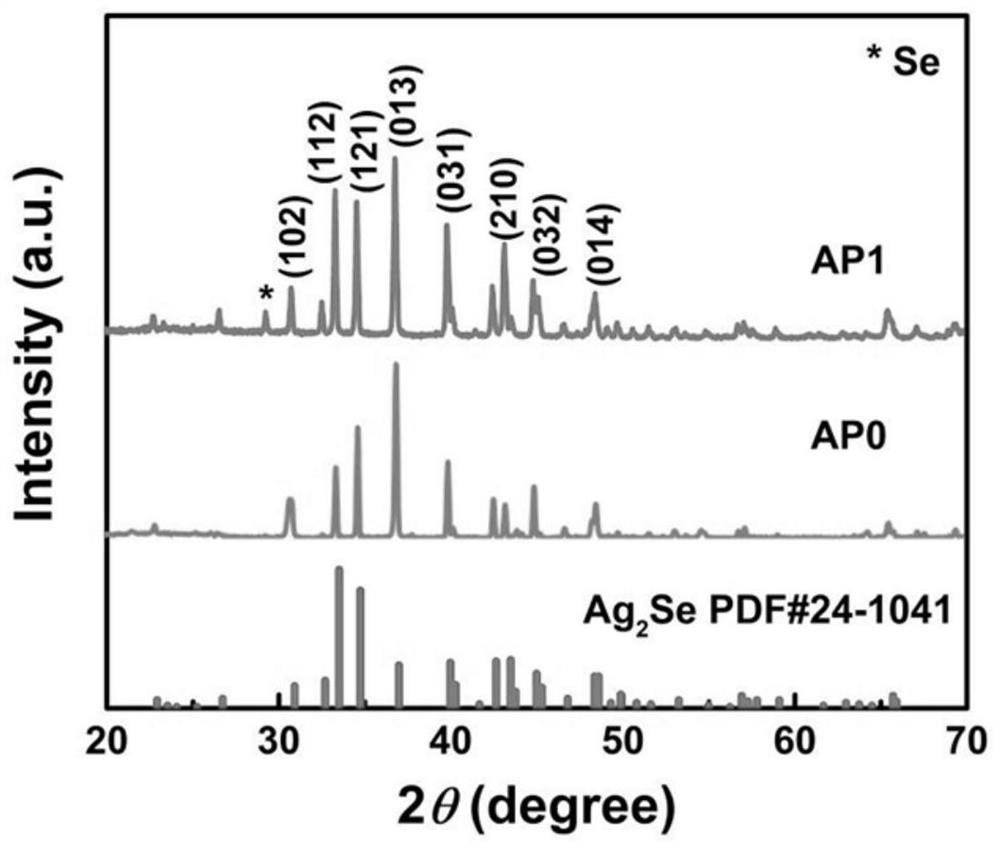

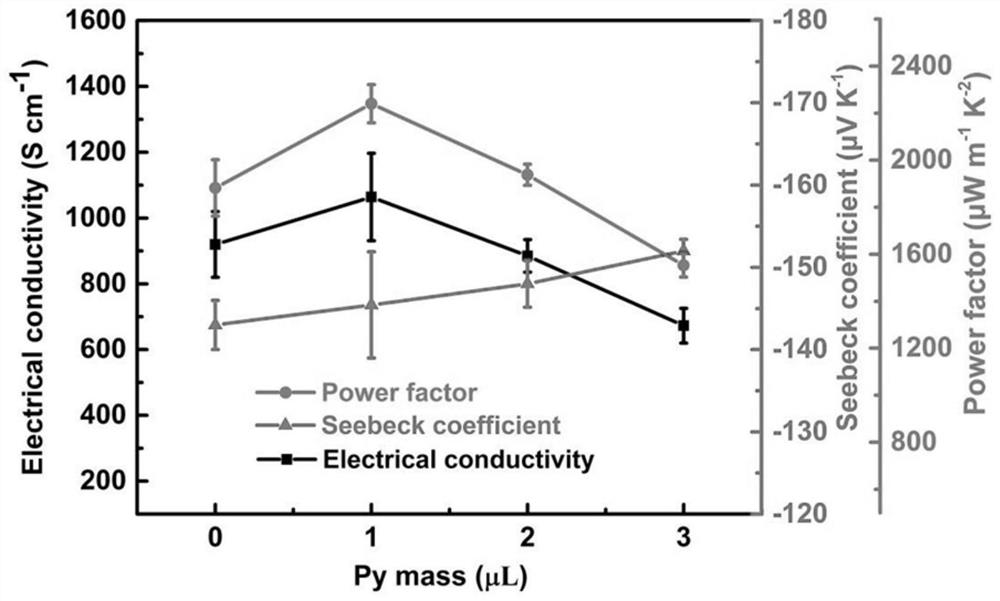

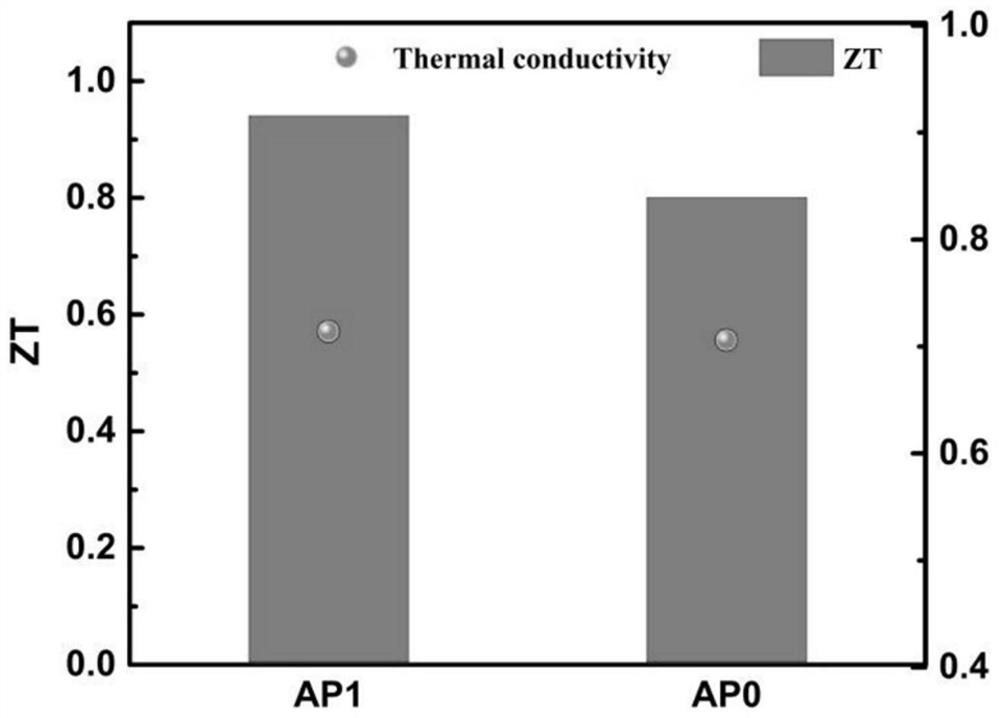

[0039] A method for preparing high-performance silver selenide / polypyrrole / nylon flexible composite thermoelectric film, the method disperses 0.5mmol selenium nanowires in 100mL ethylene glycol solution, 0.17g silver nitrate (adding amount meets silver nitrate and selenium nanometer The molar ratio of the line is 2:1) into the beaker, after stirring at 40°C for 2 hours, add 1 μL of pyrrole monomer and sonicate for 30 minutes, and add the oxidant ammonium persulfate (the addition amount meets the molar ratio of pyrrole monomer and ammonium persulfate to be 1: 5), the purpose of adding ammonium persulfate is to polymerize the pyrrole monomer into polypyrrole in situ. Stir at room temperature for 20 minutes, centrifuge at a speed of 4000r / min, extract the resulting black precipitate, and alternately add deionized water and absolute ethanol to wash at a speed of 4000r / min for 3 minutes to remove impurities. The black target product was dispersed in 30ml of absolute ethanol and ult...

Embodiment 2

[0047] A method for preparing high-performance silver selenide / polypyrrole / nylon flexible composite thermoelectric film, the method disperses 0.5mmol selenium nanowires in 100mL ethylene glycol solution, 0.17g silver nitrate (adding amount meets silver nitrate and selenium nanometer The molar ratio of the line is 2:1) into the beaker, stirred at 40°C for 2 hours, then added 2 μL of pyrrole monomer and ultrasonicated for 30 minutes, and added the oxidant ammonium persulfate (the addition amount met the molar ratio of pyrrole and ammonium persulfate to be 1:5) , The purpose of adding ammonium persulfate is to polymerize pyrrole monomers into polypyrrole in situ. Stir at room temperature for 20 minutes, centrifuge at a speed of 4000r / min, extract the resulting black precipitate, and alternately add deionized water and absolute ethanol to wash at a speed of 4000r / min for 3 minutes to remove impurities. The black target product was dispersed in 30ml of absolute ethanol and ultrason...

Embodiment 3

[0049] A method for preparing high-performance silver selenide / polypyrrole / nylon flexible composite thermoelectric film, the method disperses 0.5mmol selenium nanowires in 100mL ethylene glycol solution, 0.17g silver nitrate (adding amount meets silver nitrate and selenium nanometer The molar ratio of the line is 2:1) into the beaker, stirred at 40°C for 2 hours, then added 3 μL of pyrrole monomer and sonicated for 30 minutes, and added the oxidant ammonium persulfate (the amount added should meet the molar ratio of pyrrole and ammonium persulfate to be 1:5) The purpose of adding ammonium persulfate is to polymerize pyrrole monomers into polypyrrole in situ. Stir at room temperature for 20 minutes, centrifuge at a speed of 4000r / min, extract the resulting black precipitate, and alternately add deionized water and absolute ethanol to wash at a speed of 4000r / min for 3 minutes to remove impurities. The black target product was dispersed in 30ml of absolute ethanol and ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com