Multifunctional graphene foam and preparation method thereof

A multi-functional, olefin foam technology, applied in the field of graphene, can solve the problems of thick foam products, limited gas volume, discontinuity, etc., and achieve the effects of good performance stability, simple process and single structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

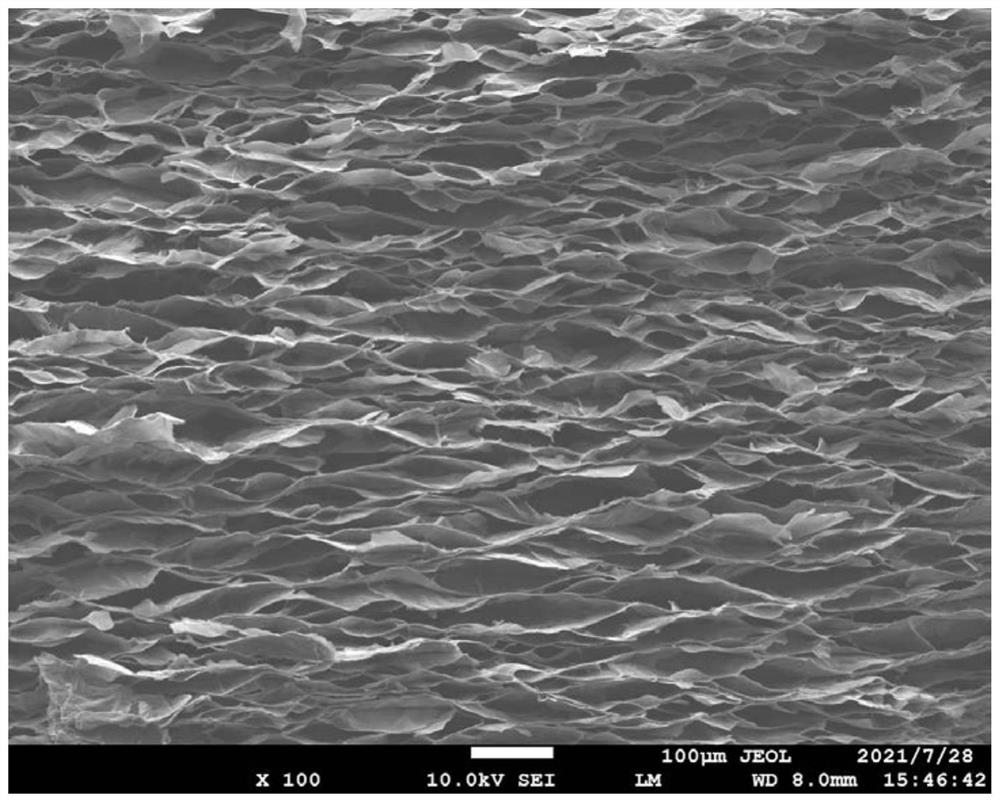

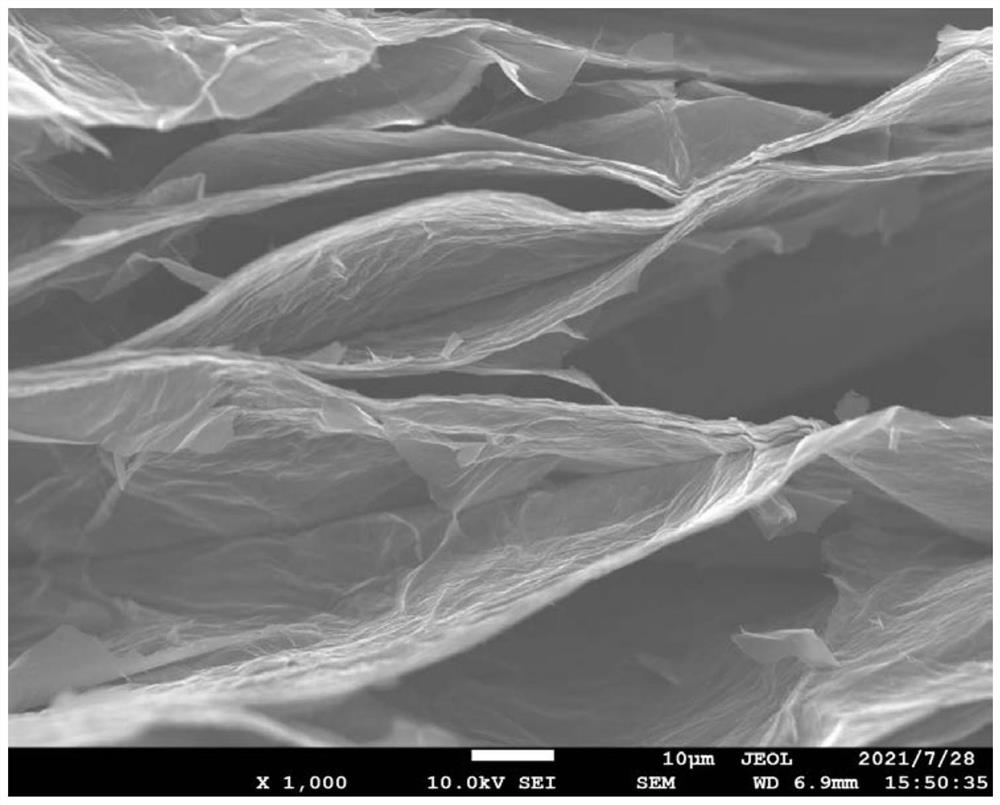

[0030] A graphene oxide coating film with a carbon-to-oxygen ratio of 1.4 (purchased from Yunnan Yuntian Morui Technology Co., Ltd.) was placed in a reaction vessel with an ultrasonic vibration function, hydrazine hydrate was selected as the reaction solution, and the graphene oxide coating film was mixed with The volume ratio of the hydrazine hydrate solution is 1:3; the reaction temperature is kept constant at 40°C, and the working power of the ultrasonic vibration is set to 2000W, and the graphene foam in a relatively wet state is obtained by the reaction. Subsequently, it was placed in a microwave oven, and the working power was set to 60kW. After 3 minutes, a dry graphene foam with a thickness of about 7mm was obtained. After sequentially undergoing high-temperature carbonization at 1200°C and graphitization at 2800°C, as figure 1 As shown in the low-magnification SEM image, the intact porous structure in the graphene foam can be seen, and the pore size distribution is 60...

Embodiment 2

[0032]A graphene oxide coating film with a carbon-to-oxygen ratio of 1.4 (purchased from Yunnan Yuntian Morui Technology Co., Ltd.) was placed in a container containing a hydrazine hydrate reaction solution. During the reaction, magnetic stirring was provided to disturb the solution, and the reaction temperature was kept constant at 40 ℃, the graphene foam in a relatively wet state is obtained by reaction. Subsequently, it was placed in a microwave oven, and the microwave frequency was set to 60kW. After 3 minutes, a dry graphene foam with a thickness of about 5 mm was obtained. After sequentially undergoing high-temperature carbonization at 1200°C and graphitization at 2800°C, as Figure 4 As shown, the microstructure observed by scanning electron microscopy can see a partially intact porous structure, and there is no obvious crosslinking between graphene layers at some positions. This is due to the inconsistency of the overall fluidity of the reaction solution due to magnet...

Embodiment 3

[0034] The graphene oxide coating film material with a carbon-to-oxygen ratio of 2.0 was placed in a reaction vessel with an ultrasonic vibration function, hydrazine hydrate was selected as the reaction solution, and the reaction temperature was kept constant at 60°C to obtain a graphene foam in a relatively wet state. Subsequently, it was placed in a microwave oven, and the microwave frequency was set to 80kW. After 2 minutes, a dry graphene foam with a thickness of about 11mm was obtained. After sequentially undergoing high-temperature carbonization at 1200°C and graphitization at 2800°C, the pore size is 50 μm to 160 μm; the graphene layers are cross-linked to form a network, and effective electrical and heat conduction channels are formed between the pores. The measured thermal conductivity of graphene foam is 145W / m K, and the conductivity can reach 5.5*10 5 S / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size distribution | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com