Low-temperature silver paste and heterojunction battery

A technology of silver paste and low temperature, applied in the direction of circuits, electrical components, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of battery components scrapped, easy to tear, etc., to improve welding tension, increase wettability, The effect of lowering the interface barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

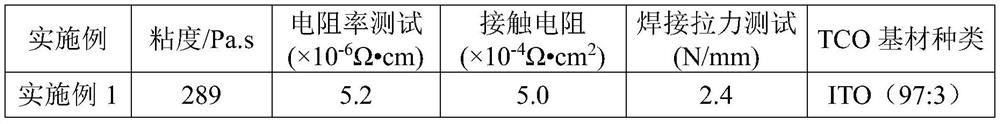

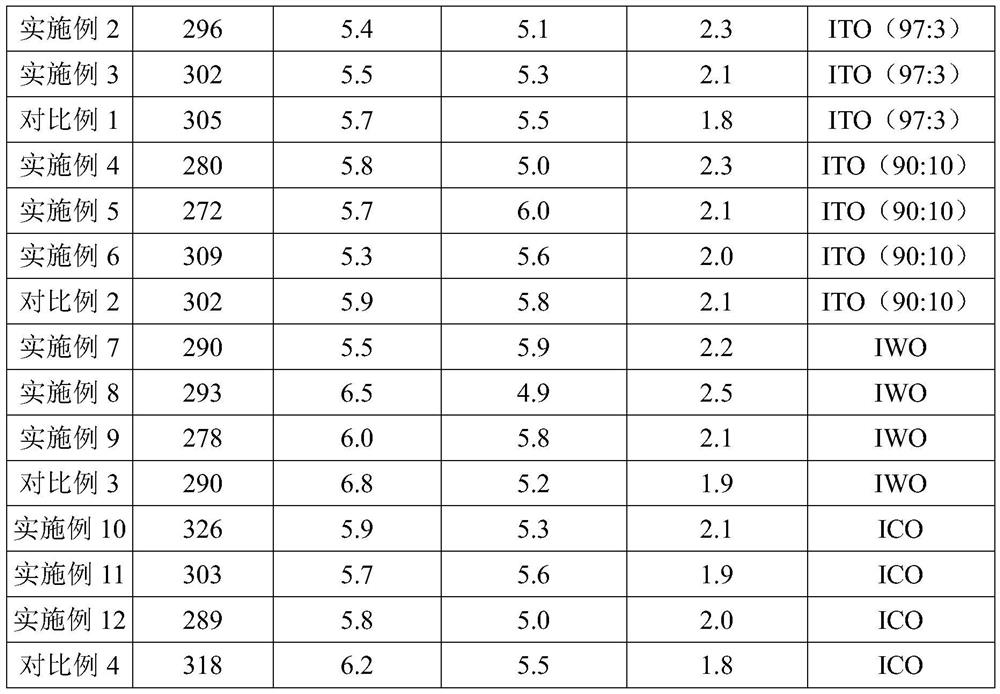

Examples

Embodiment 1

[0038] This embodiment provides a kind of low temperature silver paste, by weight, the low temperature silver paste includes:

[0039] 40 parts of flaky silver powder (average particle size 2μm, tap density 4.6g / cm 3 ), 52 parts of spherical silver powder (average particle size 0.1μm, tap density 1.6g / cm 3 ), 2 parts of silver-indium alloy (diameter is 100nm, length is 1μm, silver content is 70wt%, indium content is 30wt%), 2 parts of resorcinol formaldehyde epoxy resin (as polyphenol type glycidyl ether epoxy resin ), 1 part diglycidylhydantoin (as heterocyclic glycidyl epoxy resin), 2.5 parts polybutadiene resin (as crack growth inhibitor), 2 parts diethylene glycol butyl ether (as solvent ), 0.3 parts of isopropyl tris(dodecylbenzenesulfonyl) titanate, 0.2 parts of boron trifluoride-monoethylamine complex (as a curing agent). Wherein, the number average molecular weight of resorcinol formaldehyde epoxy resin and diglycidyl hydantoin is controlled at 800-1200.

Embodiment 2

[0041] This embodiment provides a kind of low temperature silver paste, by weight, the low temperature silver paste includes:

[0042] 45 parts of flaky silver powder (average particle size 5μm, tap density 5g / cm 3 ), 45 parts of spherical silver powder (average particle size 1μm, tap density 2g / cm 3 ), 1 part of silver-indium alloy (diameter is 200nm, length is 2μm, silver content is 80wt%, indium content is 20wt%), 1.5 parts of resorcinol formaldehyde epoxy resin (as polyphenol type glycidyl ether epoxy resin ), 1 part of 5,5-dimethylhydantoin epoxy resin (as a heterocyclic glycidyl epoxy resin), 2.5 parts of polybutadiene resin (as a crack growth inhibitor), 1.5 parts of diethylene glycol butadiene Ether (as a solvent), 0.3 parts of isopropyl tris(dioctylpyrophosphate acyloxy) titanate, 0.3 parts of boron trifluoride-monoethylamine complex (as a curing agent). Among them, the number average molecular weight of resorcinol formaldehyde epoxy resin and 5,5-dimethylhydantoin ...

Embodiment 3

[0044] This embodiment provides a kind of low temperature silver paste, by weight, the low temperature silver paste includes:

[0045] 50 parts of flake silver powder (average particle size 10μm, tap density 4.8g / cm 3 ), 38 parts of spherical silver powder (average particle size 3μm, tap density 1.6g / cm 3 ), 4 parts of silver-indium alloy (diameter is 500nm, length is 3μm, silver content is 90wt%, indium content is 10wt%), 2.5 parts of resorcinol formaldehyde epoxy resin (as polyphenol type glycidyl ether epoxy resin ), 1.6 parts of 5,5-dimethylhydantoin epoxy resin (as a heterocyclic glycidyl epoxy resin), 2.5 parts of polybutadiene resin (as a crack growth inhibitor), 1.5 parts of diethylene glycol butyl Ether (as a solvent), 0.2 parts of isopropyl tris(dioctyl phosphate acyloxy) titanate, 0.2 parts of boron trifluoride-monoethylamine complex (as a curing agent). The number average molecular weight of resorcinol formaldehyde epoxy resin and 5,5-dimethylhydantoin epoxy resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com