Silver nanowire-biological material composite transparent conductive film and preparation method and application thereof

A technology of transparent conductive films and biomaterials, applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve difficult silver nanowire electrodes, decomposition, devices Short circuit and other problems, to achieve the effect of environmental protection of the preparation process, improvement of oxidation resistance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of silver nanowire-biological material composite transparent conductive film, comprising the following steps:

[0038] 1), the preparation of silver nanowire solution and propolis solution:

[0039] Using the AgNWs solution as the precursor solution, adding isopropanol to dilute the silver nanowire dispersion, the silver nanowire ink (AgNWs solution) was finally obtained; the concentration of AgNWs was 2 mg / mL, and the solvent A was isopropanol;

[0040] The propolis was mixed with solvent B and ultrasonically uniform, the concentration of propolis was 10 mg / mL, the solvent B was absolute ethanol, and the insoluble impurities were filtered out by centrifugation to obtain a propolis solution.

[0041] 2), pretreatment of PET transparent film substrate:

[0042] PET film (thickness 125 μm) was ultrasonically cleaned with optical glass cleaner, deionized water, ethanol and acetone for 30 min, and then treated with UV / ozone at 45 W for 5 min to obtain ...

Embodiment 2

[0047] A preparation method of silver nanowire-biological material composite transparent conductive film, comprising the following steps:

[0048] 1), the preparation of silver nanowire solution and vitamin C solution:

[0049] Using the AgNWs solution as the precursor solution, adding isopropanol to dilute the silver nanowire dispersion, the silver nanowire ink (AgNWs solution) was finally obtained; the concentration of AgNWs was 5 mg / mL.

[0050]After vitamin C and solvent B are mixed, ultrasonically uniform, the concentration of vitamin C is 30 mg / mL, and the solvent B is absolute ethanol;

[0051] 2), pretreatment of PDMS transparent film substrate:

[0052] Treat the PDMS substrate with plasma for 60 s to obtain the pretreated substrate;

[0053] 3), Preparation of AgNWs / vitamin C composite transparent conductive film:

[0054] Use a scraper coater to scrape a layer of silver nanowire wet film on the pretreated substrate with a scraper, and cure it at 120°C for 20min t...

Embodiment 3

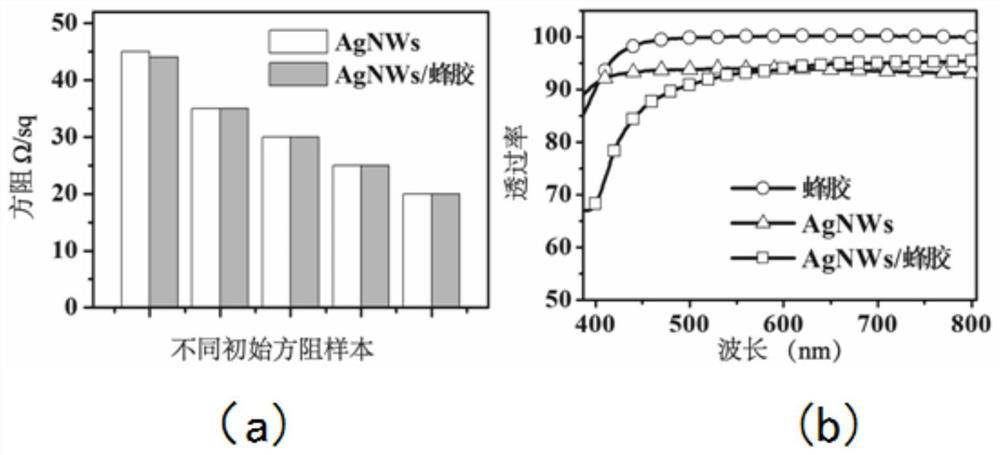

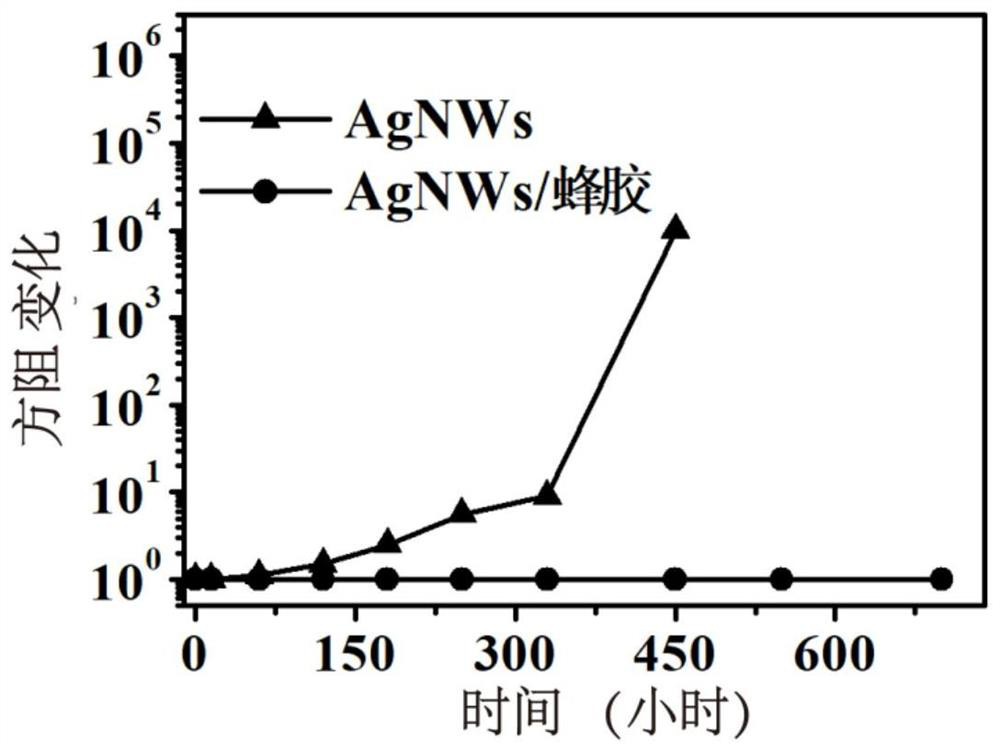

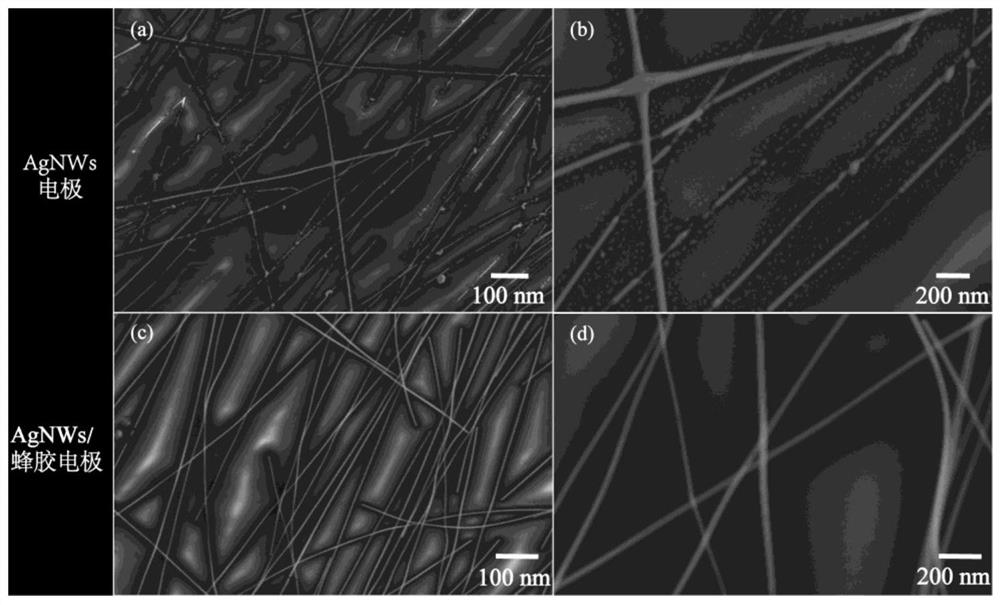

[0057] The AgNWs / propolis composite conductive film prepared in Example 1 was used as an example, and the AgNWs conductive film was prepared at the same time, and the properties of the two were compared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com