SIS derivative-modified waterborne polyurethane-epoxy resin and preparation method thereof

A water-based polyurethane and epoxy resin technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor anti-sag performance and insufficient flexibility, and achieve good anti-sag performance and bending resistance, The effect of high crosslink density and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

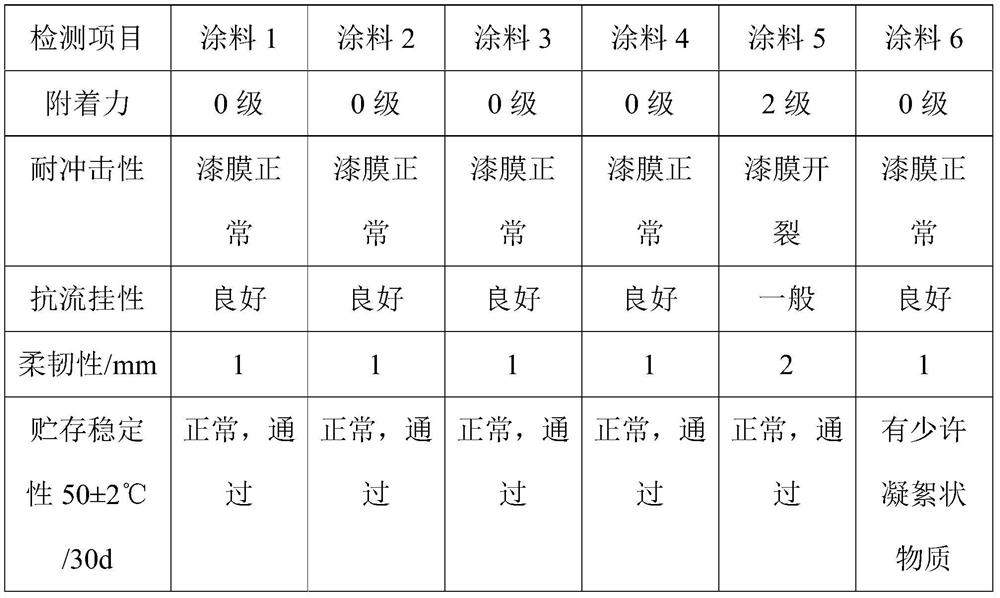

Examples

Embodiment 1

[0023] A SIS derivative modified water-based polyurethane-epoxy resin, which consists of: 50.0 parts of toluene diisocyanate, 15.0 parts of epoxy resin, 8.0 parts of SIS derivatives, 0.5 parts of benzoyl peroxide, poly 45.0 parts of carbonate diol, 2.5 parts of butylene glycol, 6.0 parts of dimethylol propionic acid, 2.5 parts of hydroxyethyl acrylate, 0.06 parts of dibutyltin dilaurate, 40.0 parts of acetone, 16.0 parts of ethyl acetate, triethyl 6.5 parts of amine, 4.0 parts of polyvinyl alcohol, 250.0 parts of deionized water.

[0024] A kind of preparation method of SIS derivative modified waterborne polyurethane-epoxy resin in the present embodiment, comprises the following steps:

[0025] a), in the titration tank, according to the weight of the formula, the SIS derivative and benzoyl peroxide are dissolved in ethyl acetate to obtain the mixed solution I;

[0026] b) In a four-port reactor, add polycarbonate diol, butanediol, and dimethylol propionic acid in sequence ac...

Embodiment 2

[0031] A SIS derivative modified water-based polyurethane-epoxy resin, which consists of: 70.0 parts of isophorone diisocyanate, 20.0 parts of epoxy resin, 10.0 parts of SIS derivatives, 0.7 parts of benzoyl peroxide in parts by weight 60.0 parts of polytetrahydrofuran diol, 4.0 parts of 1,4-cyclohexanedimethanol, 7.5 parts of dimethylolpropionic acid, 3.0 parts of hydroxyethyl acrylate, 0.07 parts of dibutyltin dilaurate, 50.0 parts of acetone, acetic acid 20.0 parts of ethyl ester, 5.5 parts of ammonia water, 5.0 parts of polyvinyl alcohol, 350.0 parts of deionized water.

[0032] A kind of preparation method of SIS derivative modified waterborne polyurethane-epoxy resin in the present embodiment, comprises the following steps:

[0033] a), in the titration tank, according to the weight of the formula, the SIS derivative and benzoyl peroxide are dissolved in ethyl acetate to obtain the mixed solution I;

[0034] b) In the four-port reactor, add polytetrahydrofuran diol, 1,4...

Embodiment 3

[0039] A waterborne polyurethane-epoxy resin modified by SIS derivatives, which consists of 60.0 parts of hexamethylene diisocyanate, 10.0 parts of epoxy resin, 7.5 parts of SIS derivatives, and 0.5 parts of benzoyl peroxide in parts by weight. 60.0 parts of polycaprolactone diol, 6.0 parts of neopentyl glycol, 6.0 parts of dimethylolpropionic acid, 3.0 parts of hydroxyethyl acrylate, 0.05 parts of dibutyltin dilaurate, 40.0 parts of acetone, ethyl acetate 15.0 parts, 9.5 parts of dimethylethanolamine, 5.0 parts of polyvinyl alcohol, and 300.0 parts of deionized water.

[0040] A kind of preparation method of SIS derivative modified waterborne polyurethane-epoxy resin in the present embodiment, comprises the following steps:

[0041] a), in the titration tank, according to the weight of the formula, the SIS derivative and benzoyl peroxide are dissolved in ethyl acetate to obtain the mixed solution I;

[0042] b) In the four-port reactor, add polycaprolactone diol, neopentyl g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap