Fishpond for aquaculture by utilizing marsh

An aquaculture, fish pond technology, applied in fish farming, application, water aeration and other directions, can solve the problems of limited return to the field, high pollution concentration, poisoning and death, etc., to save bait, good benefits, and promote growth. effect of reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

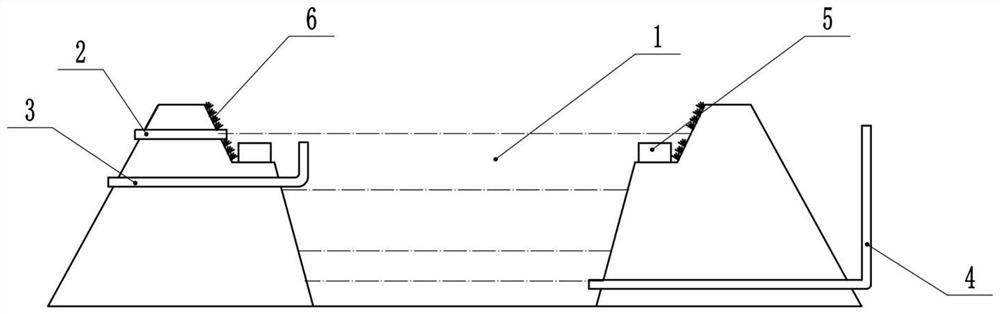

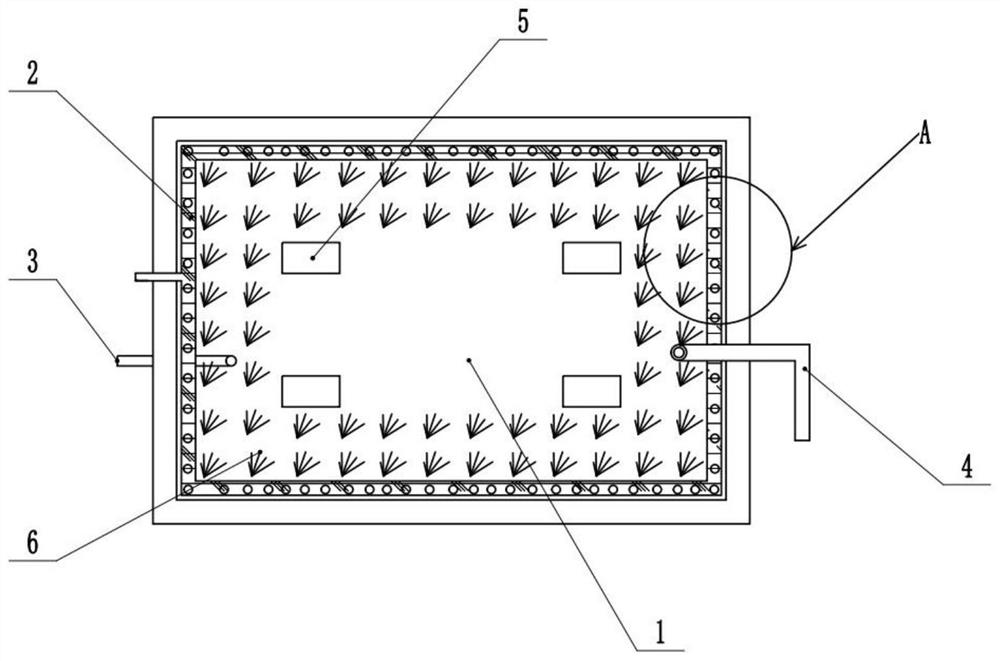

[0021] The embodiment is basically as attached figure 1 , figure 2 and image 3 Shown: a fishpond using swamp aquaculture, please refer to figure 1 Include the following steps:

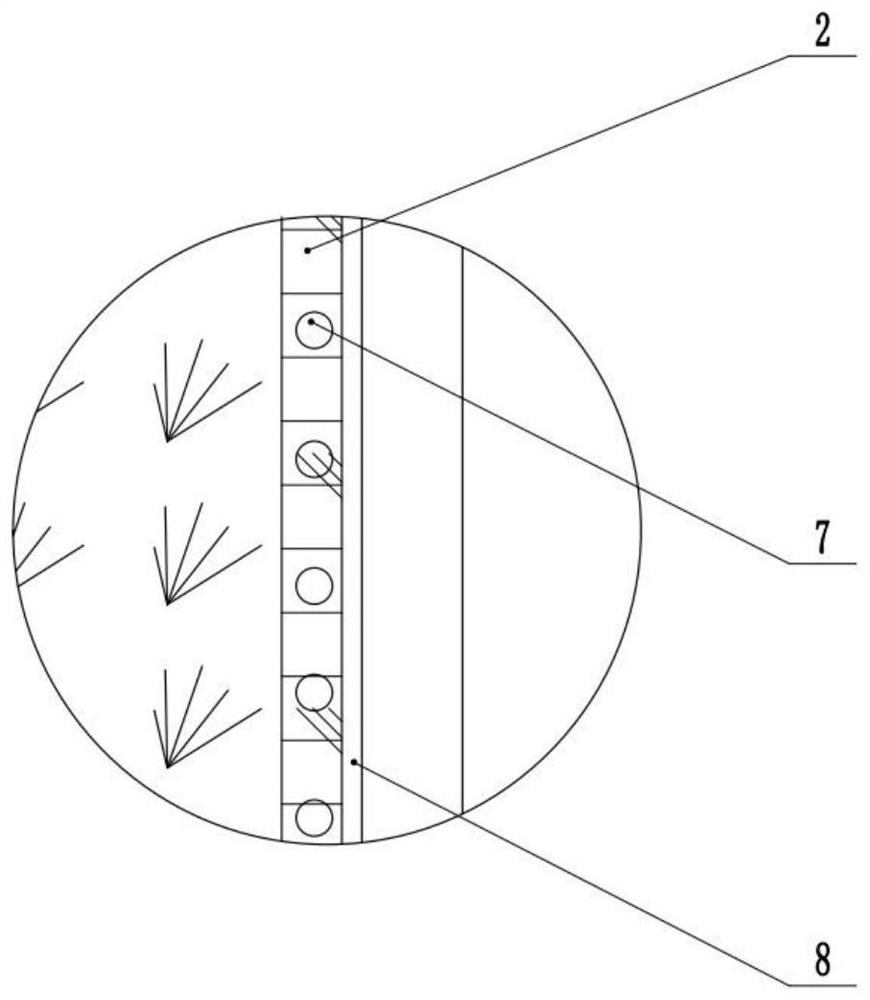

[0022] 1) Prefabricate a fish pond. The location of the fish pond needs to be located in a mild climate, good lighting conditions, and non-polluting area; The water level adjustment discharge pipe to control the water level, the bottom of the fish pond is equipped with a drainage pipe, and a multifunctional aeration device is installed in the fish pond. The water drip irrigation pipe has a drip hole every 50cm long, and the drip irrigation pipe is covered with a layer of slow-wetting cloth, and the biogas slurry flowing out of the drip irrigation pipe through the biogas slurry infiltrates evenly into the soil layer of the hybrid pennisetum planted on the downhill surface of the drip irrigation through the slow-wetting cloth , After the soil in the soil layer and the root system of hybrid penniset...

Embodiment 2

[0029] A marsh-grass-fish oxidation pond structure, comprising the following steps:

[0030] 1) A fish pond 1 is prefabricated, and the location of the fish pond 1 needs to be located in a mild climate, good lighting conditions, and a non-polluting area; One side of the fish pond 1 is provided with a discharge pipe 3 for controlling the water level, the bottom of the fish pond 1 is provided with a drain pipe 4, an aeration device 5 is installed in the fish pond 1, and a hybrid is planted on the downhill surface of the biogas slurry inlet drip irrigation pipe 2 inside the pond ridge. Pennisetum 6;

[0031] The oxidation pond has an area of 1.7 mu and a water storage capacity of 2300m 3 ~2600m 3 After the water is filled, the biogas slurry starts to enter, and the multifunctional shallow aeration device 5 is turned on to cultivate plankton and aerobic microorganisms in the water;

[0032] 2) The biogas slurry is continuously fed into the fish pond 1 through the biogas slurr...

Embodiment 3

[0037] A marsh-grass-fish oxidation pond structure, comprising the following steps:

[0038] 1) A fish pond 1 is prefabricated, and the location of the fish pond 1 needs to be located in a mild climate, good lighting conditions, and a non-polluting area; One side of the fish pond 1 is provided with a discharge pipe 3 for controlling the water level, the bottom of the fish pond 1 is provided with a drain pipe 4, an aeration device 5 is installed in the fish pond 1, and a hybrid is planted on the downhill surface of the biogas slurry inlet drip irrigation pipe 2 inside the pond ridge. Pennisetum 6;

[0039] The area of the oxidation pond is 2.0 mu, and the water storage capacity is 2600m 3 ~3000m 3 After the water is filled, the biogas slurry starts to enter, and the multifunctional shallow aeration device 5 is turned on to cultivate plankton and aerobic microorganisms in the water;

[0040] 2) The biogas slurry is continuously fed into the fish pond 1 through the biogas slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com