Negative electrode material for non-aqueous electrolyte secondary battery and preparation method thereof

A non-aqueous electrolyte and negative electrode material technology, which is applied in the direction of secondary batteries, battery electrodes, negative electrodes, etc., can solve the problems of unstable solid electrolyte interface film and large expansion effect of silicon-based negative electrode materials, and achieve controllable size and improved Conductive ion conduction performance, the effect of improving the interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Next, the preparation method of the negative electrode material is described, and the negative electrode material is prepared as follows:

[0028] S1: Evenly disperse the binder, carbon nanomaterials, silicon-based materials, and fast ion conductor materials in a solvent to make a slurry;

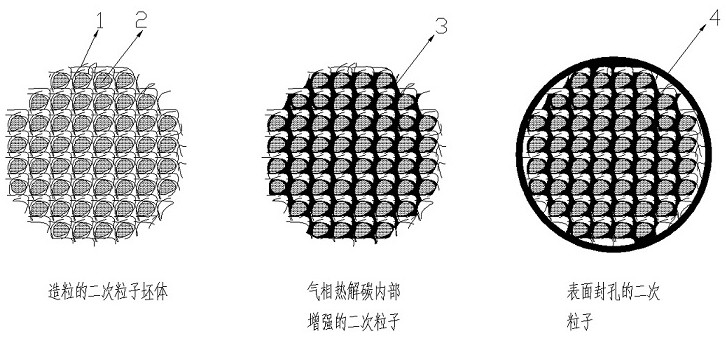

[0029] S2: Spray granulating the above slurry to obtain a secondary particle green body in which the silicon particles are connected and isolated by the carbon nanomaterial coated with the fast ion conductor layer;

[0030] S3: sintering the product of step S2 under a protective atmosphere, and then performing vapor phase infiltration deposition to obtain porous secondary particles reinforced by pyrolytic carbon;

[0031] S4: Surface coating the product of step S3 to obtain the negative electrode material.

[0032] In a preferred embodiment, the mass percentages of the substances in the slurry are: 0.5-3% of the binder, 1-10% of the carbon nanomaterial, 80%-90% of the silicon-based ...

Embodiment 1

[0040] Disperse 60g of carbon nanotubes in water with a solid content of 2%, add 230g of 10% HF aqueous solution and 290g of 10% LiOH aqueous solution, and disperse and coat LiF on the surface of carbon nanotubes; after fully stirring, Then add 1kg of SiO powder (tested by the above method that the expansion rate of SiO in a fully charged state is 135%), and finally add 20g of phenolic resin and stir evenly to make a slurry with a solid content of about 25%.

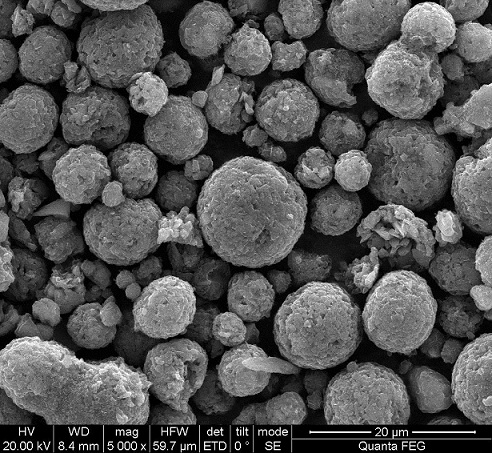

[0041] The spray granulation equipment is used for granulation, the air inlet temperature is 250 degrees, and the outlet air temperature is 90 degrees to obtain the granulated secondary particle body.

[0042] The granulated secondary particle green body was sintered at 900°C, and the heating rate was 5°C / min. After sintering, 6L / min of hydrogen-nitrogen mixed gas and 0.6L / min of acetylene were continued to be introduced, and the gas was deposited at 900°C for 3 hours to make the gas Pyrolytic carbon is generated in the ...

Embodiment 2

[0047] The other steps are the same as in Example 1, the difference is that the SiO in Example 1 is replaced by Li-doped SiO powder, the measured expansion rate of the Li-doped SiO powder in a fully charged state is 105%, and the spray granulation is adjusted Temperature and spray rate, the porosity of the secondary particles was measured to be 58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com