Columnar copper array current collector and preparation method and application thereof

A current collector and array technology, which is applied in the field of columnar copper array current collectors and its preparation, can solve the problem that the gaps in the holes are difficult to be fully utilized, and achieve the effects of easy large-scale processing, short time consumption, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of copper microrod array current collector, concrete steps are:

[0041] S1. Ultrasonic cleaning of 400 μm thick copper foil with deionized water to remove surface impurities;

[0042] S2. Conduct femtosecond laser processing experiments in an air environment; the copper foil is processed by a femtosecond pulse laser machine with a pulse width of 800fs and a wavelength of 532nm. The frequency is 200kHz, the power is 8w, the scanning interval is 40μm, and the scanning speed is 30mm / s;

[0043] S3, putting the copper foil treated in S2 into 1mol / L hydrochloric acid solution for 6 hours, removing the oxide layer on the surface, and cleaning the copper foil with deionized water and absolute ethanol successively;

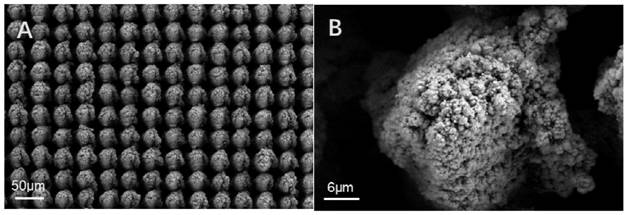

[0044] Through the above treatment, the copper microrod array current collector is obtained. Its scanning electron microscope pictures are as figure 2 As shown, their structural features at the micrometer scale and submicrometer scale are show...

Embodiment 2

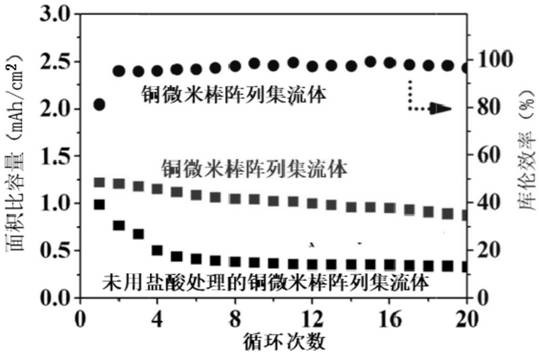

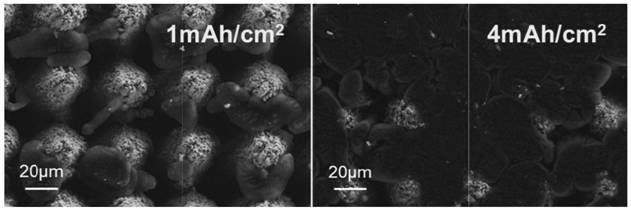

[0054] With the copper microrod array current collector that makes in embodiment 1 as lithium metal negative electrode current collector, with the LiTFSI / LiNO that dissolves in DME / DOL 3 As the electrolyte, a button cell was assembled with lithium metal as the counter electrode and the charge and discharge test was carried out. After 1mAh / cm respectively 2 、4mAh / cm 2 After the lithium metal is deposited, its scanning electron microscope picture is as follows Figure 5 As shown, lithium metal is deposited between the pillars in the form of bulk, without the formation of lithium dendrites. The first Coulombic efficiencies of the battery are 81.1% and 93.6%, respectively, considering that the design capacity of the current collector is 5mAh / cm 2 , it can be seen that the matching degree between the actual capacity and the design capacity significantly affects its first Coulombic efficiency. When the area specific capacity is 4mAh / cm 2 , the battery can perform more than 80 s...

Embodiment 3

[0058] A layer of nanoscale Au was plated on the surface of the same copper array current collector as in Example 1, and the same battery assembly and electrochemical tests were performed. The first Coulombic efficiency of the battery can be further improved, up to 97.4%. Compared with the copper microrod array current collector, the overpotential of charge and discharge after gold plating can be reduced from 50mV to 20mV, such as Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com