Hydrogenation catalyst and preparation method and application thereof

A hydrogenation catalyst and catalyst technology are applied in catalytic reactions, chemical instruments and methods, preparation of organic compounds, etc., to achieve the effects of improving catalytic activity, increasing loading rate, and high reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Hydrogenation catalyst preparation:

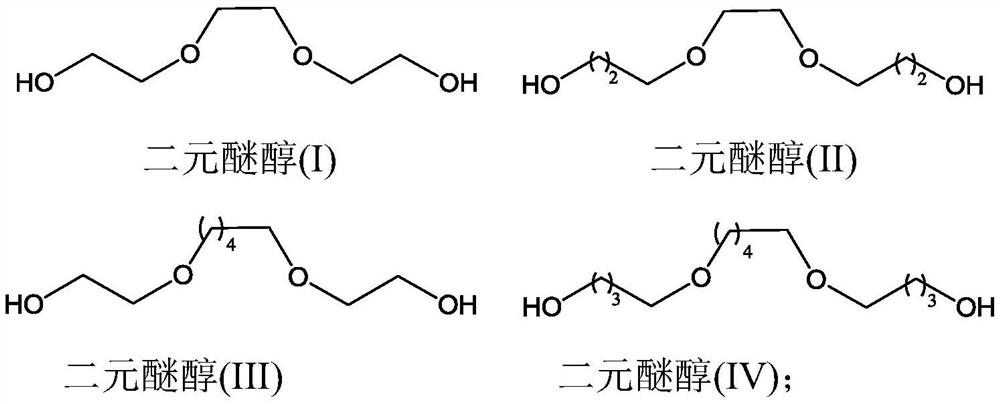

[0050]a. 200g chloromethylated polystyrene resin, 10g dibasic ether alcohol (I), 1000g toluene, 100g 20wt% sodium hydroxide aqueous solution were mixed and then refluxed and stirred for 3 hours, cooled to room temperature and suction filtered, and deionized Washed 3 times with water until there is no chloride ion, heated and dried at 70°C for 5 hours under 10KPa vacuum to obtain hydrogenation catalyst precursor B1.

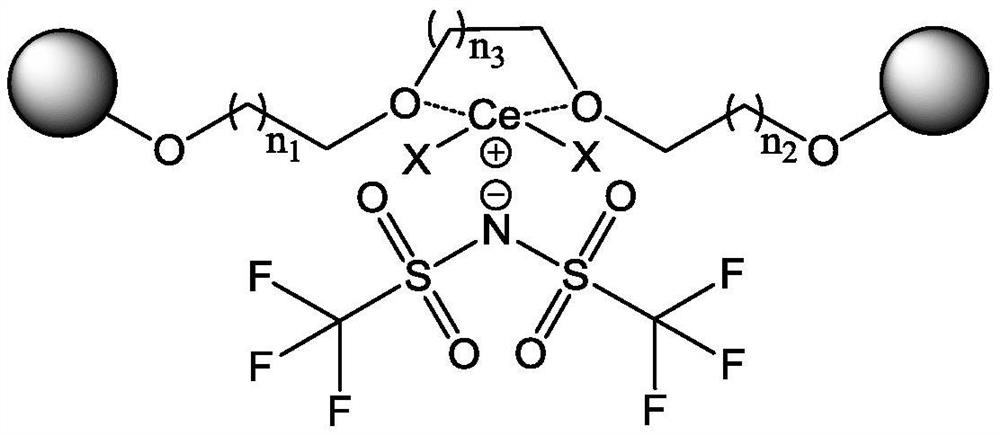

[0051] b. Mix 200g of catalyst precursor B1, 4g of cerium chloride, 4g of bistrifluoromethanesulfonyl imide, 40g of cesium carbonate and 1200g of dichloromethane, then reflux and stir for 2 hours, cool to room temperature and filter with deionized Wash with water three times, heat and dry at 80°C for 6 hours under 20KPa vacuum to obtain hydrogenation catalyst a.

[0052]

[0053] (2) Catalyst activity evaluation:

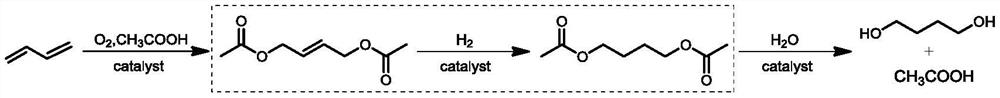

[0054] Add 80g of 1,4-diacetoxybutene, 200g of xylene, and 10g of the above-mentioned catalyst in...

Embodiment 2-4

[0057] The preparation and activity evaluation of the hydrogenation catalyst were carried out according to the steps of Example 1, and the corresponding preparation parameters and activity evaluation results are shown in Tables 1-3.

[0058] Table 1 Catalyst precursor B preparation conditions

[0059]

[0060] Table 2 catalyst preparation conditions

[0061]

[0062] Table 3 Catalyst b-d catalytic activity evaluation

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com