Preparation method and application of self-repairing high-temperature-resistant polyurethane elastomer

A polyurethane elastomer, self-healing technology, applied in the field of self-healing polymer material synthesis, polyurethane elastomer, can solve the problems of polyurethane piston damage, low wear resistance, temperature rise in the wear pump, etc., to overcome damage and high hardness , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

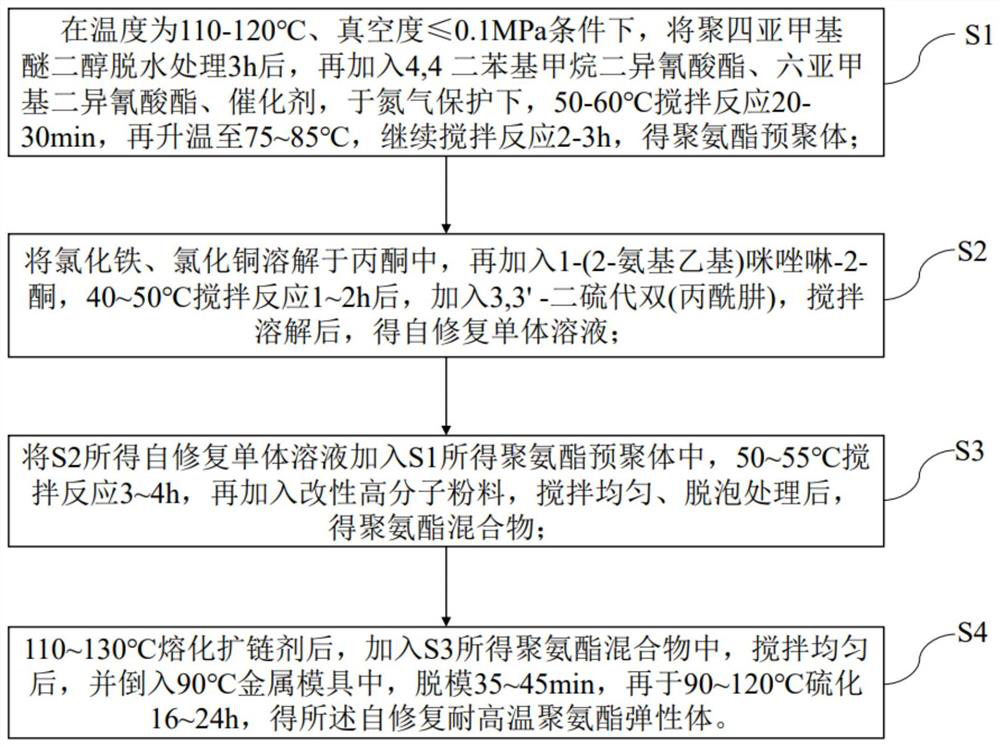

Method used

Image

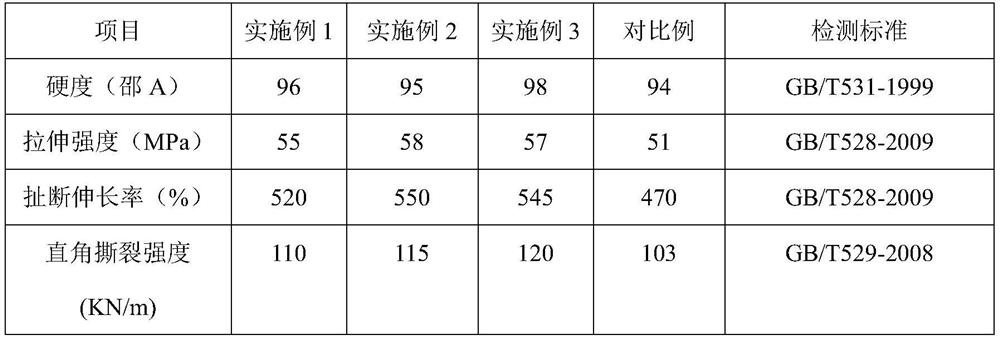

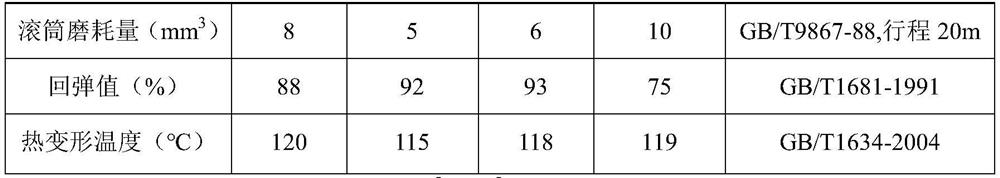

Examples

Embodiment 1

[0027] A preparation method of self-healing high temperature resistant polyurethane elastomer, comprising the following steps:

[0028] S1: Grind the aramid fiber into particles with a particle size of 10 μm, and then add it to a phosphoric acid solution with a mass concentration of 50% at a ratio of 1g / 1mL. After stirring and dispersing, heat up to 100°C for 15 minutes, filter, and then Wash with distilled water until neutral to obtain modified aramid fiber;

[0029] S2: Weigh 55 parts of polytetramethylene ether glycol, 20 parts of 4,4 diphenylmethane diisocyanate, 20 parts of hexamethylene diisocyanate, 3,3'-dithiobis (Propionylhydrazide) 2 parts, 1-(2-aminoethyl) imidazolin-2-one 1 part, ferric chloride 0.2 parts, copper chloride 0.2 parts, acetone 20 parts, 3,3'-dichloro- 9 parts of 4,4'-diaminodiphenylmethane, 0.2 parts of dibutyltin dilaurate, 2 parts of modified aramid fiber;

[0030] S3: At a temperature of 110°C and a vacuum degree of ≤0.1MPa, dehydrate polytetrame...

Embodiment 2

[0035] A preparation method of self-healing high temperature resistant polyurethane elastomer, comprising the following steps:

[0036] S1: Grind the modified ultra-high molecular weight polyethylene into particles with a particle size of 50 μm, and then add it to potassium dichromate, concentrated sulfuric acid with a mass fraction of 98%, and water at a ratio of 1 g / 1.25 mL. 2:10 mass ratio of the mixed solution prepared, 25 ℃ room temperature stirring treatment for 40min, after filtration, and then washed with distilled water until neutral, that is, modified ultra-high molecular weight polyethylene;

[0037] S2: Weigh 60 parts of polytetramethylene ether glycol, 25 parts of 4,4 diphenylmethane diisocyanate, 20 parts of hexamethylene diisocyanate, 3,3'-dithiobis (Propionylhydrazide) 3 parts, 1-(2-aminoethyl) imidazolin-2-one 1.5 parts, ferric chloride 0.3 parts, copper chloride 0.3 parts, acetone 25 parts, hydroquinone-bis(β-hydroxy 14 parts of ethyl) ether, 0.25 part of di...

Embodiment 3

[0043] A preparation method of self-healing high temperature resistant polyurethane elastomer, comprising the following steps:

[0044] S1: Grind aramid fiber into particles with a particle size of 10-100 μm, then add it to a phosphoric acid solution with a mass concentration of 50% at a ratio of 1g / 1.5mL, stir and disperse, heat up to 120°C for 60 minutes, and filter After that, it is washed with distilled water to neutrality, and the modified aramid fiber is obtained;

[0045] S2: Weigh 65 parts of polytetramethylene ether glycol, 30 parts of 4,4 diphenylmethane diisocyanate, 25 parts of hexamethylene diisocyanate, 3,3'-dithiobis (propionylhydrazide) 4 parts, 1-(2-aminoethyl) imidazolin-2-one 2 parts, ferric chloride 0.4 parts, copper chloride 0.4 parts, acetone 30 parts, 3,3'-dichloro- 18 parts of 4,4'-diaminodiphenylmethane, 0.3 parts of triethylamine, 4 parts of modified aramid fiber;

[0046] S3: Under the conditions of temperature 110-120°C and vacuum degree ≤0.1MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com