Preparation method of modified lithium ion battery diaphragm

A lithium-ion battery, modified technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems that limit the application of diaphragms, achieve good cycle stability, improve electrical conductivity, and good electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of Nanodiamond Modified Commercial PP Diaphragm

[0032] The nano-diamond powder is heated to 500° C. under a hydrogen atmosphere in a vacuum chamber (99.99% hydrogen, passing through the chamber at 50 sccm), and cooled to room temperature under hydrogen flow;

[0033] Dissolve 0.005g of hydrogenated nano-diamond powder in 4ml of ethanol solution, and obtain NDs colloidal solution after ultrasonication for 1 hour;

[0034] The NDs colloidal solution was coated on the commercial polypropylene separator, and after being placed in the air for a week, the NDs-modified PP separator material was obtained, which was recorded as sample 2#, and the ordinary PP separator was recorded as comparative sample 1#.

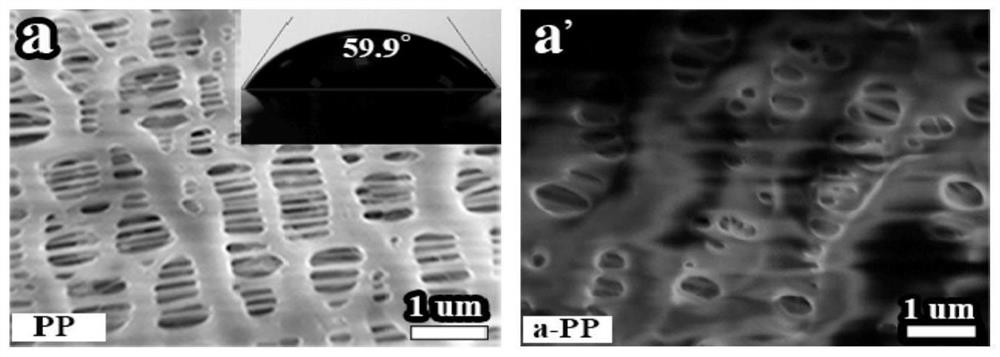

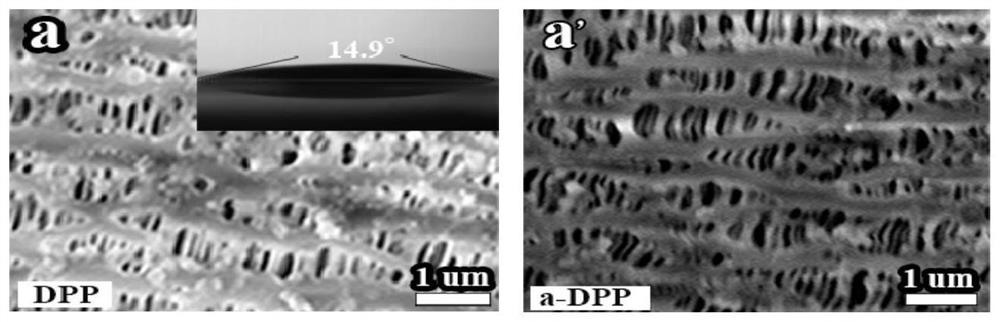

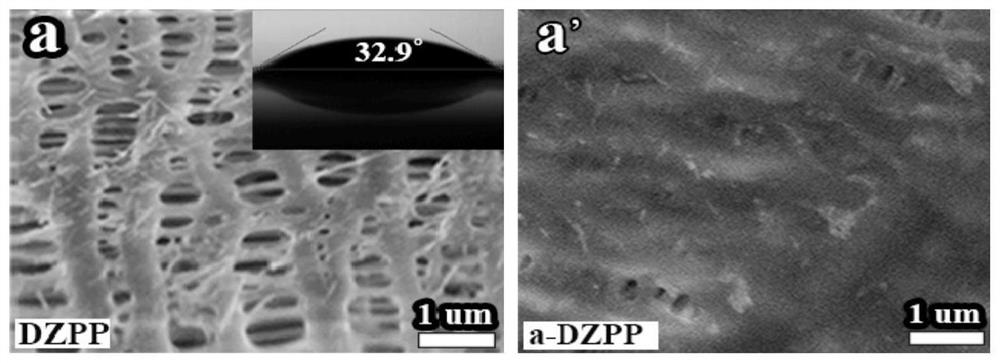

[0035] The scanning electron micrographs of samples 1# and 2# are shown in figure 1 with figure 2 , in the figure a represents before cycle, a' represents after cycle, the TEM images of adsorbed particles on the DPP separator are shown in Figure ...

Embodiment 2

[0037] Example 2: Preparation of Nanodiamond / Zinc Carbonate Modified Commercial Polypropylene Diaphragm

[0038] 1) Take Zn(AC) at a molar ratio of 2.4:2:4:1 2 2H 2 O, CTAB (cetyltrimethylammonium bromide), NaOH and EDA (ethylenediamine), are dissolved in ethanol respectively to obtain respective ethanol solutions;

[0039] 2) The ethanol solution of CTAB, NaOH and EDA was dropped into the Zn(AC) 2 2H 2 In the ethanol solution of O, stir while adding dropwise, gradually form a light yellow precipitate;

[0040] 3) adding nano-diamonds to the solution of step 2) and continuing to stir for 30 minutes, the amount of nano-diamonds is Zn(AC) 2 2H 2 0.5wt% of O, the suspension was moved to an autoclave, heated at 180°C for 8h, the supernatant was discarded, the precipitate was taken out, and the nano-diamond / zinc oxide composite material ZnO / NDs was obtained after drying;

[0041] 4) Dissolve 0.01g of ZnO / NDs powder in 4ml of ethanol solution, and obtain ZnO / NDs colloidal solu...

Embodiment 3

[0045] Example 3: Use PP, DPP, DZPP separators as lithium-ion battery components.

[0046] The lithium ion battery negative electrode is composed of 80wt% graphite material (active material), 10wt% binder (polyvinylidene fluoride, PVDF) and 10wt% conductive agent carbon black. The three were mixed and ground for 0.5h, then put into a container, and a certain amount of 1-methyl-2-pyrrolidone (NMP, solvent) was added into the container, and then placed on a magnetic stirrer and stirred at a constant speed for 6h, so that the mixture became a viscous fluid. Copper foil is used as a current collector, and the above-mentioned mixed viscous material is coated on the copper foil, and the coating density must be uniform. The temperature of the vacuum drying oven was set at 120° C., and the above-mentioned copper foil smear was taken and placed in the drying oven. After timing for 12 hours, it was taken out for use. The prepared copper foil smear is cut into several electrode discs wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com