Universal method for preparing nitrogen-doped graphene by recycling metal salt through 3d printing

A nitrogen-doped graphene, 3D printing technology, applied in the fields of environmental materials and energy, can solve the problems of high sintering temperature, harmful etching conditions, non-recyclable templates, etc., achieve uniform shrinkage, reduce experimental risks, and flexible structure selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

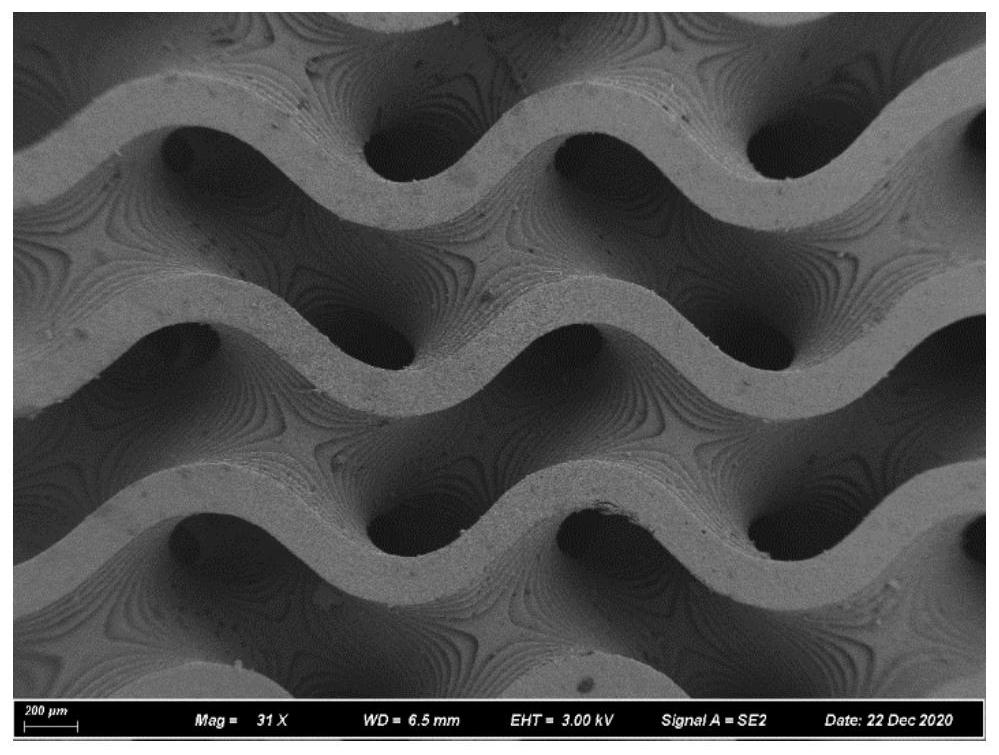

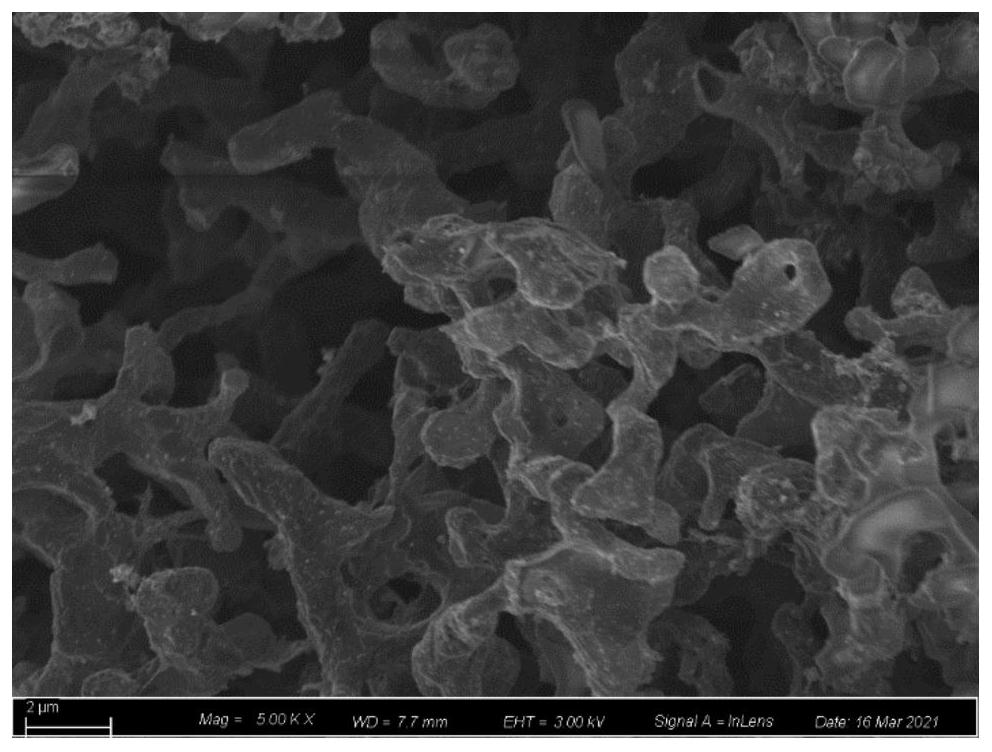

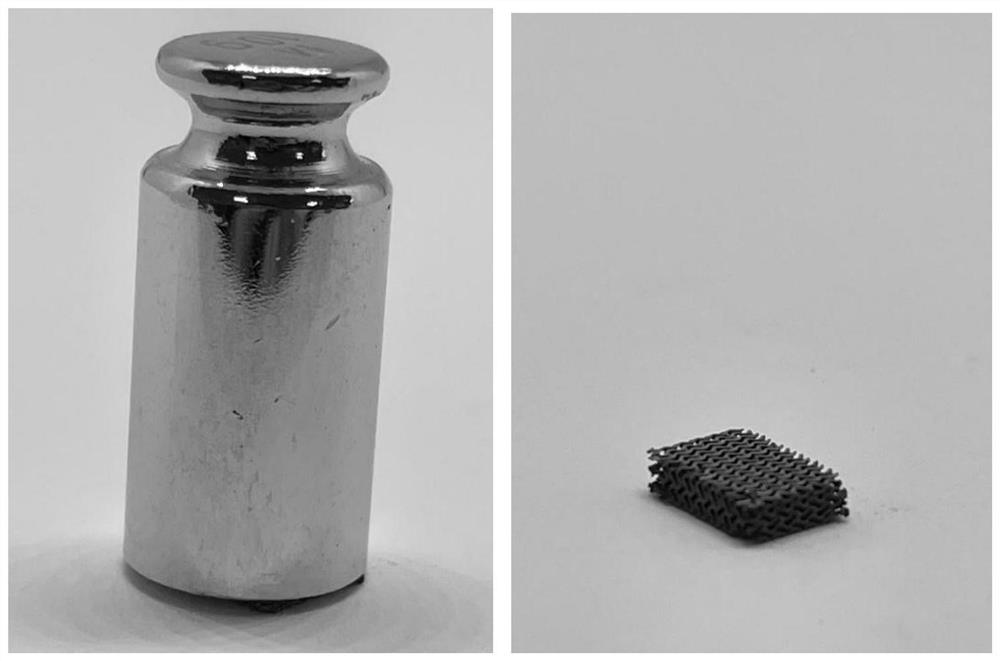

[0032] Fabrication of graphene foams templated with metallic nickel. With 56g nickel sulfate, 3mL Variquat CC 42NS, 22ml hexanediol diacrylate, 3ml ethoxylated trimethylolpropane triacrylate, 0.5g diphenyl-(2,4,6-trimethylbenzyl Acyl)phosphine, mixed and stirred at room temperature for 24 hours. A uniform nickel sulfate resin is obtained. Afterwards, it was designed into a double helix structure using digital light processing technology and printed out. Finally, the structure was sintered in a muffle furnace at 1100 °C for 5 hours. A nickel oxide template was prepared. Afterwards, the nickel oxide template is first reduced to a metal nickel template by using an argon-hydrogen mixed gas at 600° C. for ten hours to keep warm. Subsequently, using chemical deposition, pyrrole was used as a carbon source and nitrogen source, after 40 minutes of heat preservation at 800°C, it was rapidly cooled to room temperature, and the metal nickel template was removed with dilute acid. The...

example 2

[0034] Fabrication of graphene foam templated with metallic cobalt. With 58g cobalt sulfate, 3mL Variquat CC 42NS, 22ml hexanediol diacrylate, 3ml ethoxylated trimethylolpropane triacrylate, 0.5g diphenyl-(2,4,6-trimethylbenzyl Acyl)phosphine, mixed and stirred at room temperature for 24 hours. A homogeneous cobalt sulfate resin is obtained. Afterwards, it was designed into a double helix structure using digital light processing technology and printed out. Finally, the structure was sintered in a muffle furnace at 1100 °C for 5 hours. A cobalt oxide template was prepared. Afterwards, the cobalt oxide template is first reduced to a metal cobalt template by using an argon-hydrogen mixed gas at 600° C. for ten hours at a temperature of 10 hours. Subsequently, using chemical deposition, pyrrole was used as the carbon source and nitrogen source, after being kept at 800°C for 40 minutes, it was rapidly cooled to room temperature, and the metal cobalt template was removed with di...

example 3

[0036] Fabrication of graphene foams templated with metallic iron. With 28g ferric sulfate nonahydrate, 3mL Variquat CC 42NS, 11ml hexanediol diacrylate, 1.5ml ethoxylated trimethylolpropane triacrylate, 0.5g diphenyl-(2,4,6-trimethyl benzoyl) phosphine, mixed and stirred at room temperature for 24 hours. A uniform iron sulfate resin is obtained. Afterwards, it was designed into a double helix structure using digital light processing technology and printed out. Finally, the structure was sintered in a muffle furnace at 800 °C for 5 hours. Iron oxide templates were prepared. Afterwards, the iron oxide template is first reduced to a metal iron template by using an argon-hydrogen mixed gas at 600° C. for ten hours to keep it warm. Subsequently, using chemical deposition, pyrrole was used as the carbon source and nitrogen source, after being kept at 800°C for 40 minutes, it was rapidly cooled to room temperature, and the metal iron template was removed with dilute acid. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com