Electrolyte for manufacturing electrolyte copper foil and application of electrolyte

A technology of electrolyte and copper foil, which is applied in electrolysis process, electroforming, etc., can solve the problems that copper foil cannot increase the tensile strength and elongation, and achieve the effects of inhibiting recrystallization rate, excellent mechanical properties, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

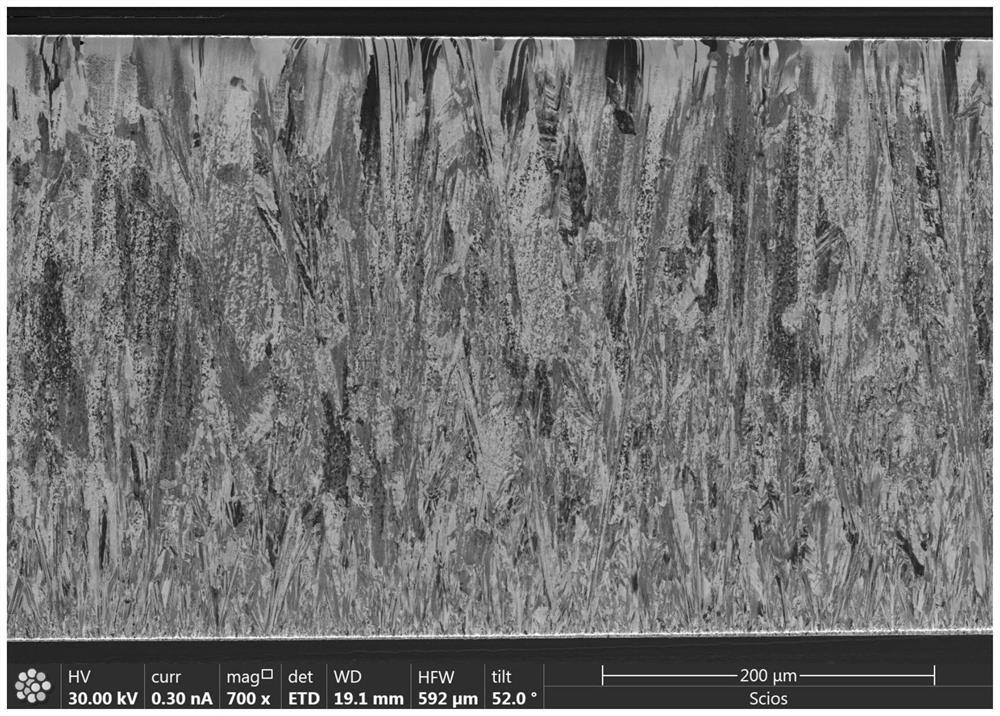

Image

Examples

Embodiment 1

[0072] This embodiment provides an electrolytic solution for copper foil manufacturing, the electrolytic solution comprising:

[0073] Copper ion 30g / L, sulfuric acid 30g / L, chloride ion 30ppm, inhibitor 50ppm, auxiliary agent 300ppm, pure water 250mL; among them, the inhibitor is gelatin with a coagulation value of 100 bloom, and the auxiliary agent is sodium polystyrene sulfonate with a molecular weight of 40,000 .

[0074] This embodiment provides a method for preparing copper foil using the above electrolyte, the method comprising:

[0075] (1) DC electroplating

[0076] a. Cathode pretreatment. The high-purity titanium plate is used as the cathode, and it undergoes the processes of alkali washing, pickling, and water washing in sequence.

[0077] b. DC plating. Immerse the titanium plate cathode and phosphorus copper anode (phosphorus content 0.05wt.%) in the above electrolytic solution, apply 300rpm mechanical stirring, and control the constant temperature of the pla...

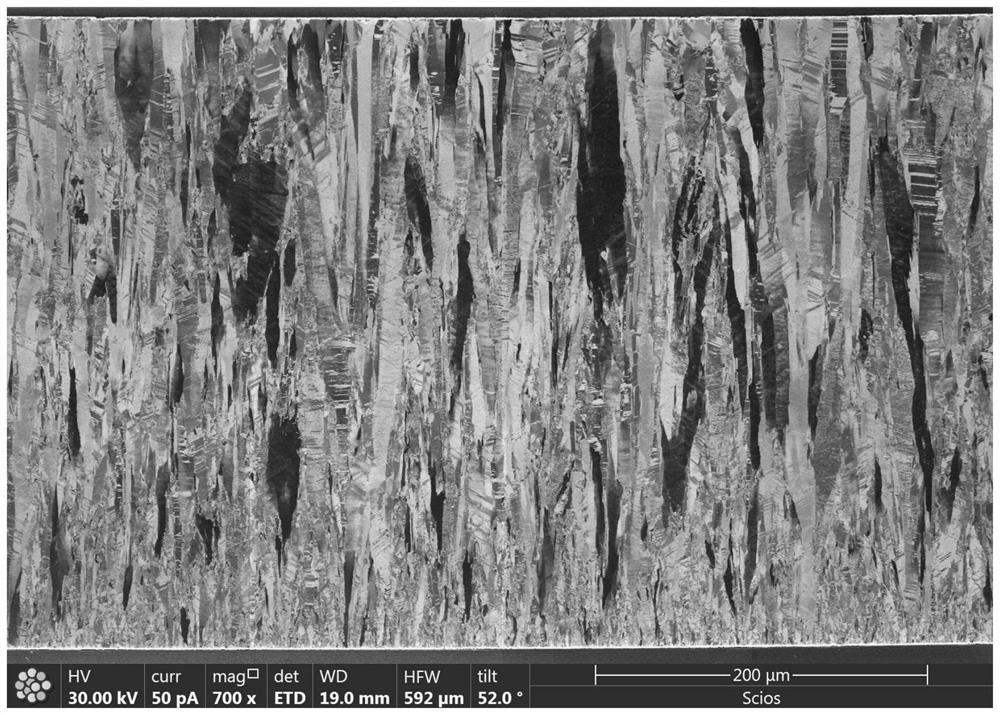

Embodiment 2

[0082] The difference between this embodiment and embodiment 1 is that the temperature of the annealing treatment in step (2) is 250°C.

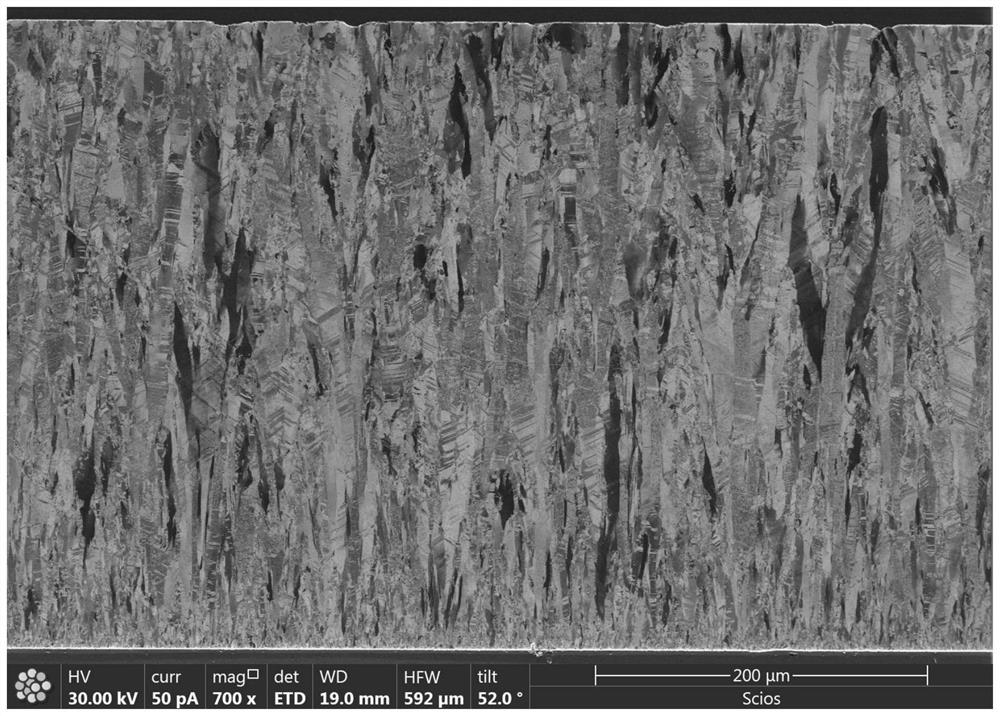

Embodiment 3

[0084] The difference between this embodiment and embodiment 1 is that the temperature of the annealing treatment in step (2) is 300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com