Reforming hydrogen production method, nano cuprous oxide-zinc oxide composite catalyst and preparation method and cyclic regeneration method of nano cuprous oxide-zinc oxide composite catalyst

A nano-cuprous oxide and composite catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve the potential safety hazards and loss of catalytic activity of hydrogen. , large consumption of hydrogen energy, etc., to achieve the effect of being environmentally friendly, easy to obtain, and avoiding oxidative deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention provides the preparation method of high-temperature self-activated nano-cuprous oxide-zinc oxide composite catalyst described in the above technical scheme, comprising the following steps:

[0060] mixing the rod-shaped zinc oxide and copper salt solution to obtain a zinc oxide-copper ion dispersion;

[0061] Mixing the stabilizer, reducing agent and water to obtain a stabilizer-reducing agent system;

[0062] The stabilizer-reductant system is added dropwise into the zinc oxide-copper ion dispersion liquid to perform a reduction reaction to obtain a high-temperature self-activating nano cuprous oxide-zinc oxide composite catalyst.

[0063] The invention can prepare the high-temperature self-activating nano-cuprous oxide-zinc oxide composite catalyst at normal temperature and pressure by using commercially available conventional reagent materials. The raw material cost is low, the production cycle is extremely short, and the preparation is simple. ...

Embodiment 1

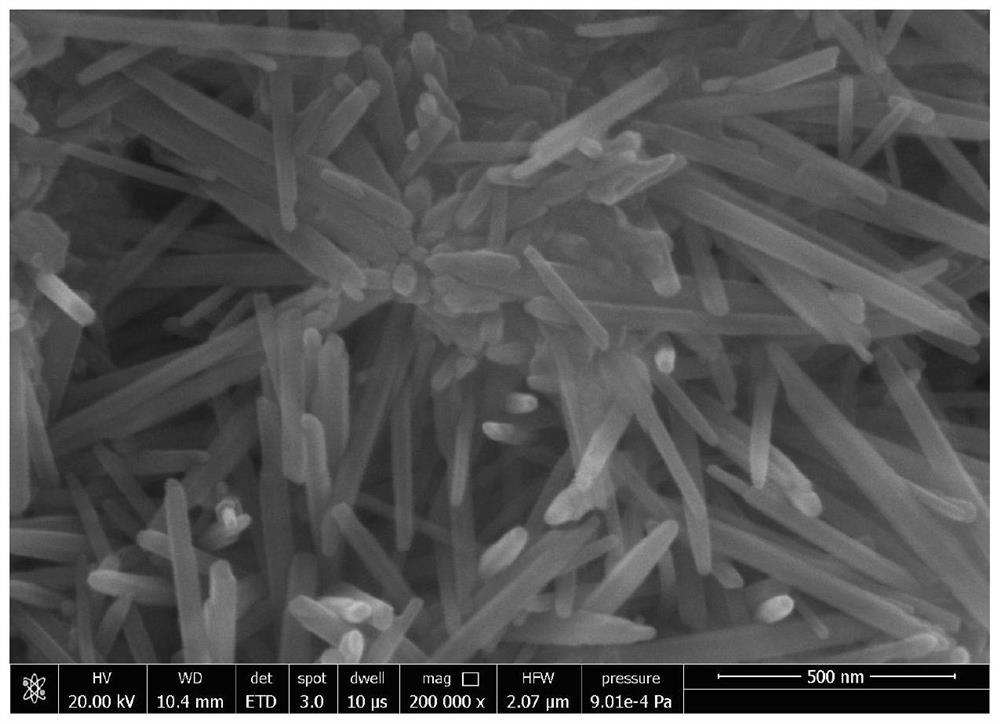

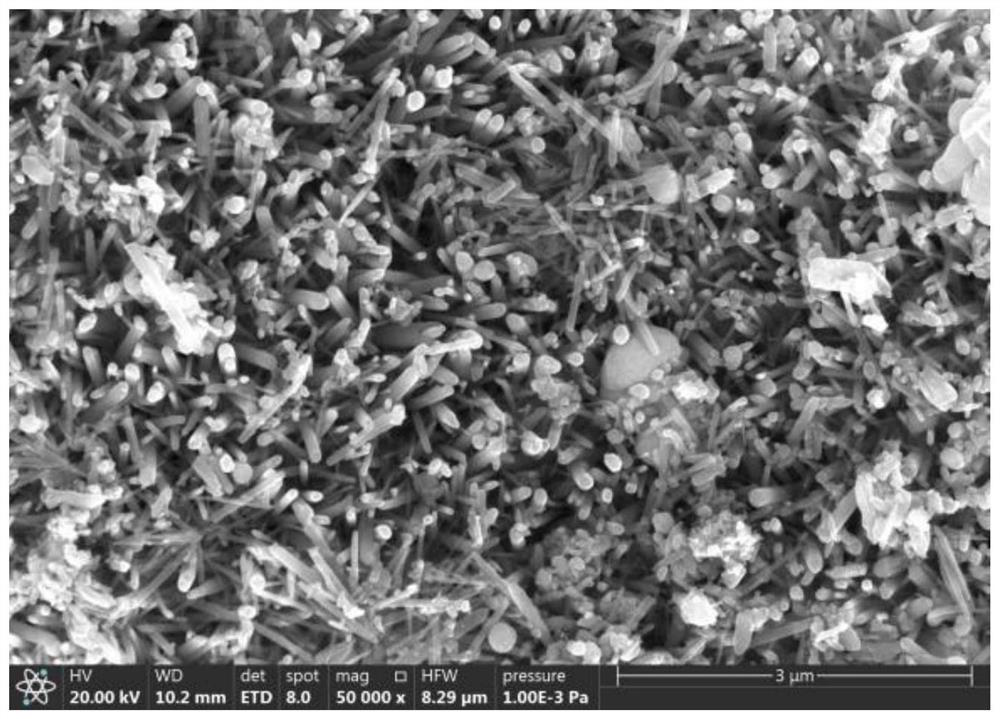

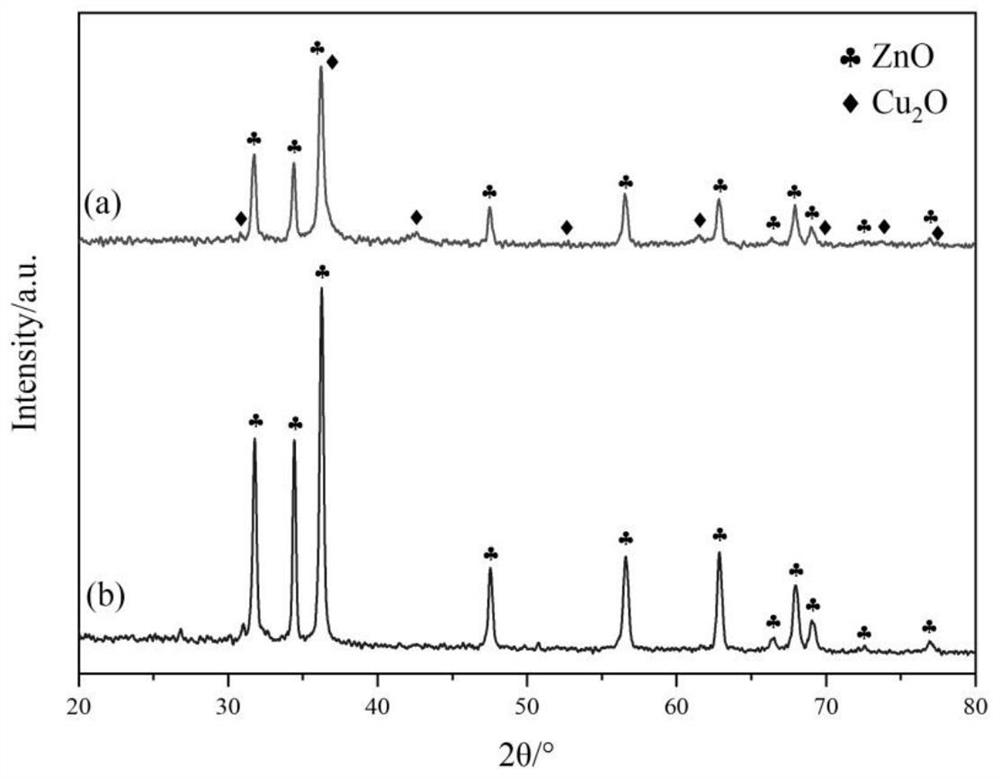

[0083] Generate rod-shaped zinc oxide by direct precipitation method: Weigh 7.08g of NaOH, dissolve it in deionized water to make the sodium ion concentration reach 4mol / L, and heat it to 70°C in a constant temperature magnetic stirrer, then weigh The zinc acetate dihydrate of 9.72g is dissolved in deionized water to form a zinc acetate dihydrate solution with a zinc ion concentration of 1mol / L. The magnetic stirrer makes it fully stirred to form a transparent solution. The zinc acetate dihydrate solution is mixed with 0.5 drops / L Add drop by drop to the NaOH solution at a rate of 1 second, and the reaction is completed after 1 hour of heat preservation; the reaction vessel is naturally cooled to room temperature, the solution is taken out, centrifuged, washed with distilled water, and dried to obtain rod-shaped zinc oxide.

[0084] According to the mass ratio of copper ions to rod-shaped zinc oxide of 1:9, prepare a 0.2mol / L copper sulfate pentahydrate solution, add 2.7g of th...

Embodiment 2

[0088] Generate rod-shaped zinc oxide by direct precipitation method: Weigh 7.08g of NaOH, dissolve it in deionized water to make the sodium ion concentration reach 4mol / L, and heat it to 70°C in a constant temperature magnetic stirrer, then weigh The zinc nitrate hexahydrate of 13.16g is dissolved in deionized water to form a zinc nitrate hexahydrate solution with a zinc ion concentration of 1mol / L. A magnetic stirrer makes it fully stirred to form a transparent solution. The zinc nitrate hexahydrate solution is mixed with 0.5 drops / L Add drop by drop to the NaOH solution at a rate of 1 second, and the reaction is completed after 1 hour of heat preservation; the reaction vessel is naturally cooled to room temperature, the solution is taken out, centrifuged, washed with distilled water, and dried to obtain rod-shaped zinc oxide.

[0089] According to the mass ratio of copper ions to rod-shaped zinc oxide of 1:9, prepare a 0.2mol / L copper chloride dihydrate solution, add 2.7g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com