Carbon material lithium metal composite negative electrode and preparation method and application thereof

A carbon material and lithium metal technology, which is applied in the field of high energy density lithium battery and its electrode material preparation, can solve the problem of the high density of the metal three-dimensional current collector frame itself, which affects the overall energy density of the lithium metal composite negative electrode, and affects the lithium metal composite negative electrode. Safety and other issues, to achieve the effect of facilitating the promotion of industrial production, excellent cycle stability, and good practical prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

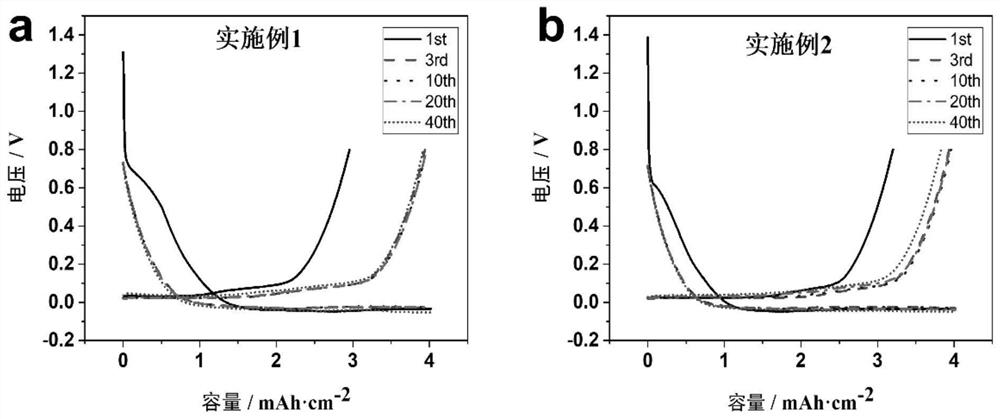

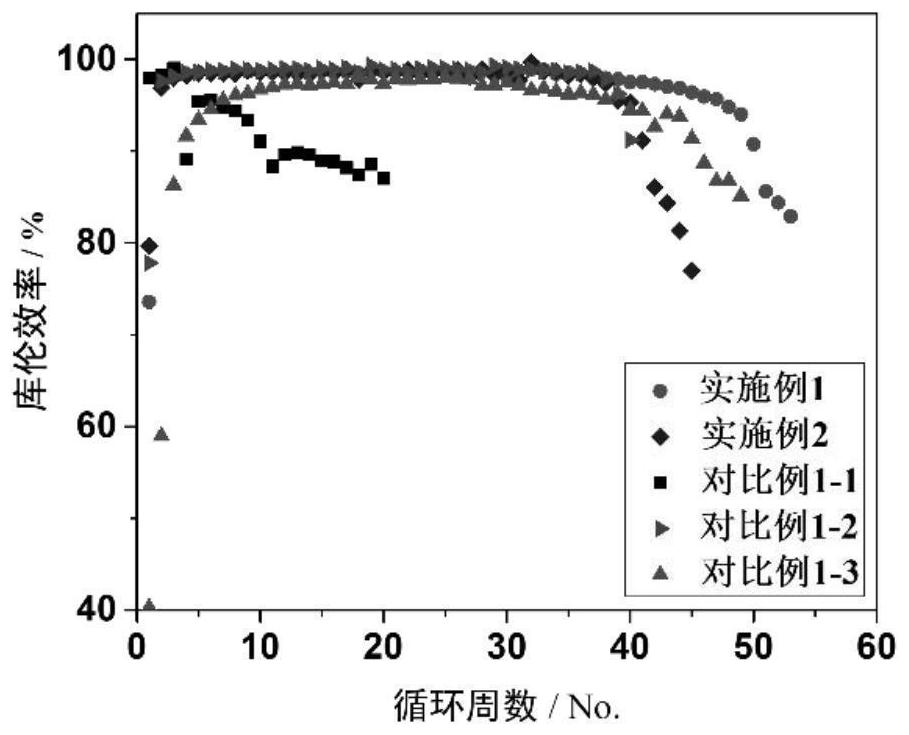

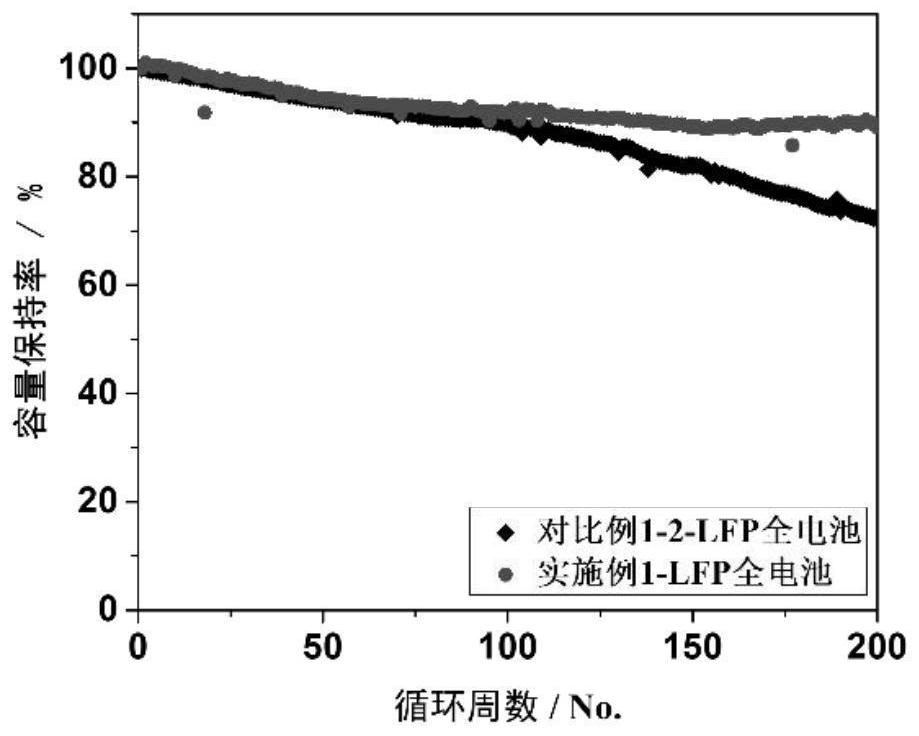

Embodiment 1

[0042] In this embodiment, a carbon material lithium metal composite negative electrode is prepared by air oxidation of hard carbon, and the specific steps are as follows:

[0043] 1. Weigh hard carbon particles with an average particle size of 5 μm and place them in a tube furnace with an air flow of 100L h -1 Pass high-purity air into the furnace.

[0044] 2. Set the tube furnace to heat up at 5°C min -1 Heating from room temperature to 300°C and keeping it warm for 6h, then cooling down to room temperature naturally to obtain hard carbon materials treated by air oxidation, which is recorded as the 300°C-6h group.

[0045] 3. Weigh the 300°C-6h group hard carbon, acetylene black, polymethylcellulose sodium and styrene-butadiene latex mixture with mass fractions of 90%, 2%, 4% and 4%, and use a defoaming mixer to fully stir them evenly And use deionized water to adjust to a suitable state of fluidity.

[0046] 4. Use a coating mold with a thickness of 400 μm to evenly coat...

Embodiment 2

[0067] In this embodiment, a carbon material lithium metal composite negative electrode is prepared by coating the surface of hard carbon with silver, and the specific implementation steps are as follows:

[0068] 1. Weigh hard carbon particles with an average particle size of 5 μm, mix them with a surfactant, and disperse them in deionized water by ultrasonic.

[0069] 2. Use 2wt% silver nitrate aqueous solution as the silver source, configure the silver ammonia solution, and fully mix the silver ammonia solution with the dispersion system in step 1.

[0070] 3. Use 40% formaldehyde aqueous solution as a reducing agent, add it to the mixed solution in step 2 in excess, heat and stir for 20 minutes, after the reaction is complete, suction filter and dry the resulting product to obtain a silver-coated hard carbon material.

[0071] 4. Weigh the mixture of silver-coated hard carbon, acetylene black, polymethylcellulose sodium and styrene-butadiene latex with a mass fraction of 9...

Embodiment 3

[0075] In this embodiment, a carbon material lithium metal composite negative electrode is prepared by air oxidation of graphite, and the specific implementation steps are as follows:

[0076] 1. Weigh the graphite powder and place it in the tube furnace with an air flow of 100L h -1 Pass high-purity air into the furnace.

[0077] 2. Set the tube furnace to heat up at 5°C min -1 After heating from room temperature to 400°C, heat preservation for 6h, and then naturally cooling to room temperature to obtain graphite treated by air oxidation, which is recorded as the 400°C-6h group.

[0078] 3. Weigh the 400°C-6h group graphite, acetylene black, polymethylcellulose sodium and styrene-butadiene latex mixture with mass fractions of 90%, 2%, 4% and 4%, respectively, use a defoaming mixer to fully stir evenly and use Adjust the deionized water to a suitable state of fluidity.

[0079] 4. Use a coating mold with a thickness of 400 μm to evenly coat the slurry on the copper foil, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com