Animal chew food and preparation method thereof

A chewing and food technology, which is applied in the field of animal chewing food and its preparation, can solve the problems of loss of effective components, breeding of bacteria, and difficulty in chewing by animals, and achieves excellent content stability, easy absorption and utilization, and uniform distribution of components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

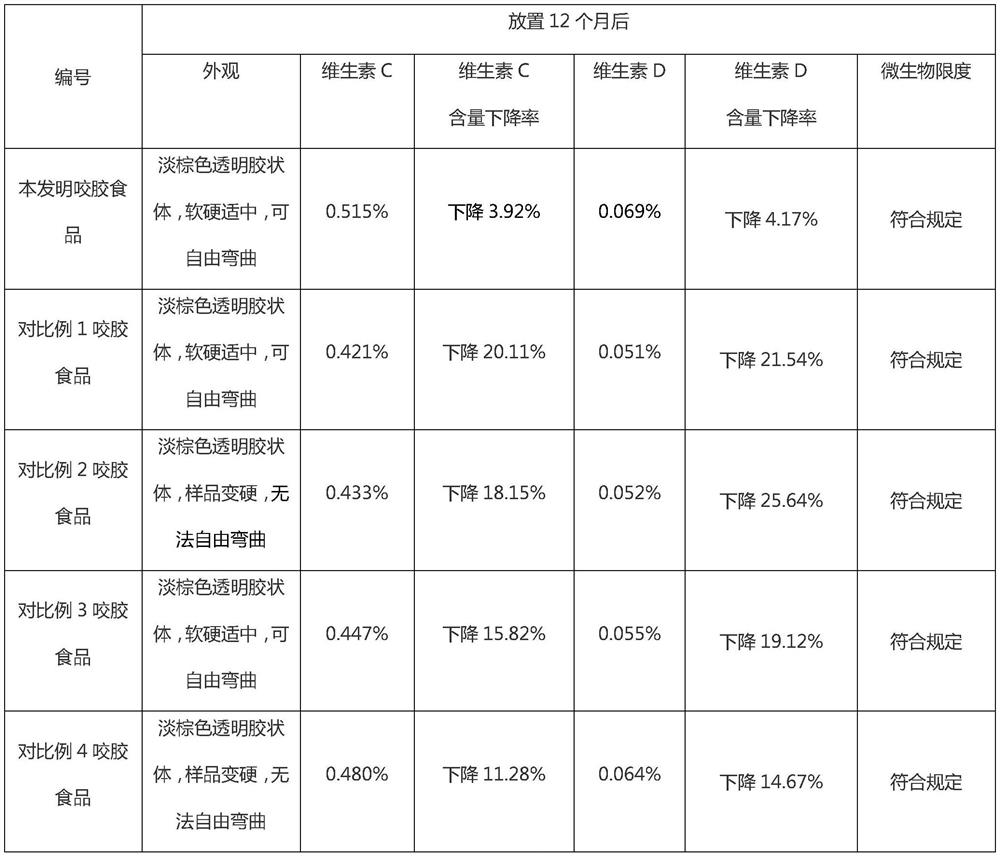

Examples

Embodiment 1

[0031] A preparation method of animal chewing gum food, carried out according to the following steps:

[0032] (1) Preparation of mixed powder: mix 6 parts of calcium carbonate, 15 parts of corn flour, 8 parts of cowhide powder, 8 parts of pigskin powder and 0.6 part of beef-flavored pet food attractant according to parts by weight, and pulverize through a 100-mesh sieve to obtain a mixed powder ;

[0033] (2) Preparation of mixed solution: according to parts by weight, 0.3 part of potassium sorbate, 0.1 part of citric acid, 0.6 part of salt and 0.02 part of white granulated sugar are dissolved in the mixed solution of purified water, and the mass ratio of potassium sorbate and purified water is 1: 10;

[0034] (3) Preparation of nutrient solution: heat purified water to 60°C, add 2 parts by weight of methyl cellulose while stirring at 20 rpm, and after the methyl cellulose is completely dissolved, add 0.5 parts of cysteine, 0.5 parts of Vitamin C, 0.06 part of vitamin D, 0....

Embodiment 2

[0040] A preparation method of animal chewing gum food, carried out according to the following steps:

[0041](1) Preparation of mixed powder: mix 10 parts of calcium carbonate, 18 parts of corn flour, 12 parts of cowhide powder, 12 parts of pigskin powder and 0.9 part of beef-flavored pet food attractant according to parts by weight, pulverize through 100 mesh sieves, and obtain mixed powder ;

[0042] (2) Preparation of mixed solution: according to parts by weight, 0.6 part of potassium sorbate, 0.3 part of citric acid, 0.8 part of salt and 0.05 part of white granulated sugar are dissolved in the mixed solution of purified water, and the mass ratio of potassium sorbate and purified water is 1: 12;

[0043] (3) Preparation of nutrient solution: heat purified water to 70°C, add 4 parts by weight of methyl cellulose while stirring at 30 rpm, and after the methyl cellulose is completely dissolved, add 0.8 parts of cysteine, 0.5 to 0.7 parts of vitamin C, 0.08 parts of vitamin ...

Embodiment 3

[0049] A preparation method of animal chewing gum food, carried out according to the following steps:

[0050] (1) Preparation of mixed powder: mix 8 parts of calcium carbonate, 16 parts of corn flour, 10 parts of cowhide powder, 10 parts of pigskin powder and 0.8 part of beef-flavored pet food attractant according to parts by weight, pulverize through 100 mesh sieves, and obtain mixed powder ;

[0051] (2) Preparation of mixed solution: according to parts by weight, 0.5 part of potassium sorbate, 0.2 part of citric acid, 0.7 part of salt and 0.04 part of white granulated sugar are dissolved in the mixed solution of purified water, and the mass ratio of potassium sorbate and purified water is 1: 11;

[0052] (3) Preparation of nutrient solution: heat purified water to 65°C, add 3 parts by weight of methyl cellulose while stirring at 25 rpm, and after the methyl cellulose is completely dissolved, add 0.6 parts of cysteine, 0.6 parts of Vitamin C, 0.07 part of vitamin D, 0.9 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com