A marine biomedical material for skin wound repair and its preparation method and application

A technology for skin wounds and marine organisms, applied in medical science, bandages, absorbent pads, etc., can solve problems such as poor wound healing quality, and achieve the effects of large encapsulation rate, good permeability, and appropriate mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

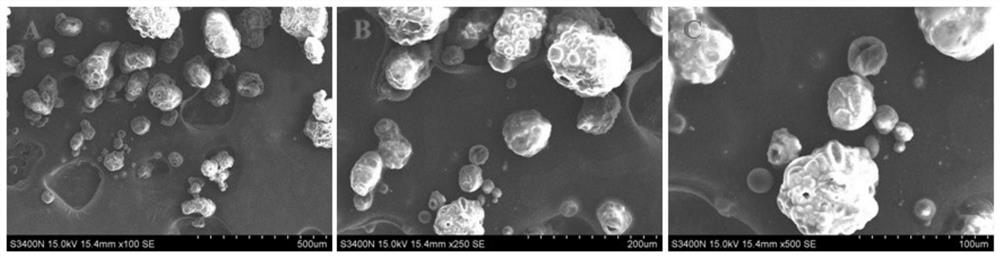

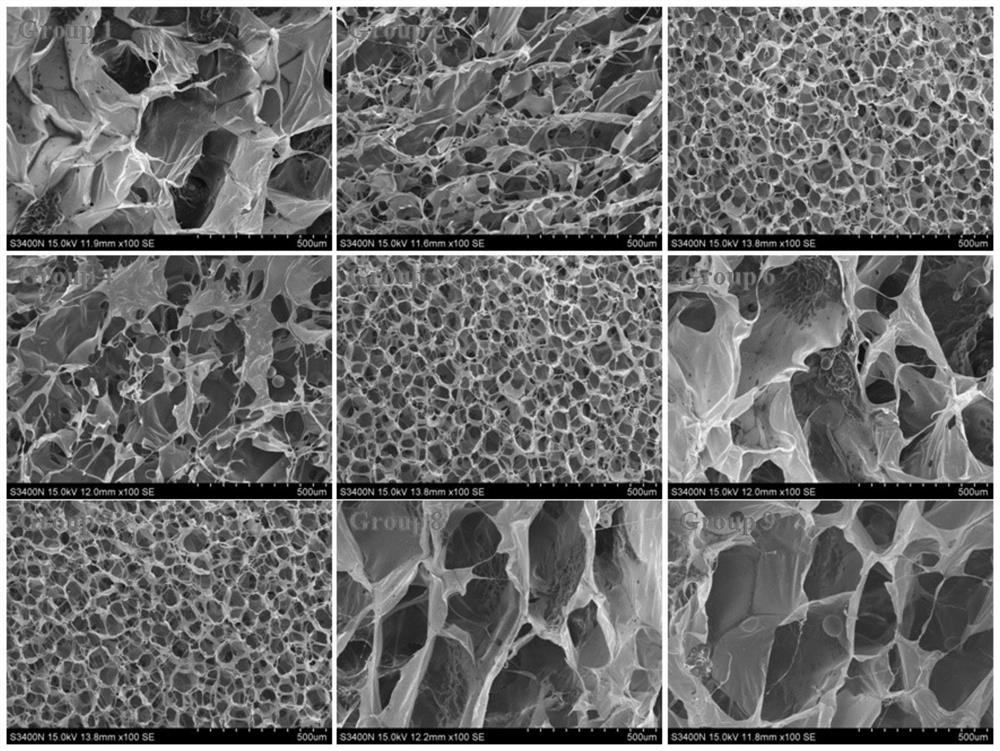

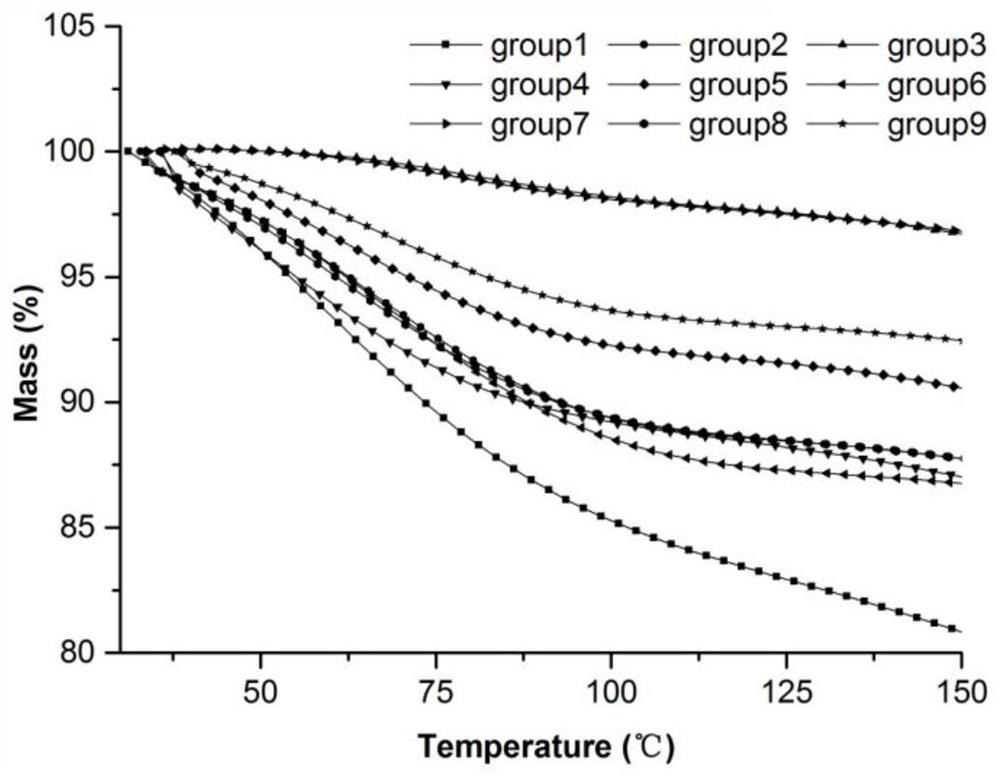

[0075] (1) Preparation of PDGF-BB@calcium alginate microspheres: Dissolve sodium alginate (purchased from Shanghai McLean Biochemical Technology Co., Ltd., purity 98%) in distilled water to prepare a concentration of 2% w / v alginic acid Sodium solution, by mass ratio 1:1.0×10 -5 Add PDGF-BB, stir well to make water phase; measure a certain volume of olive oil (purchased from Shanghai McLean Biochemical Technology Co., Ltd.), add Tween 80 (from Shanghai McLean Biochemical Technology Co., Ltd.) at a ratio of 1% v / v purchased from the company), stirred at 600 rpm for 2 h, and prepared into an organic phase; measure 100 mL of organic phase, add 20 mL of aqueous phase under stirring at 650 rpm, stir at 750 rpm for 1 h, and add 40 mL of calcium chloride with a concentration of 1% w / v (from Shanghai Mike Lin Biochemical Technology Co., Ltd.) solution, stirred at 500 rpm for 1 h, then added 10 mL of isoacetone (Tianjin Fuyu Chemical Reagent Factory, AR grade), stirred at 400 rpm for 3...

Embodiment 2

[0086] (1) Preparation of PDGF-BB@calcium alginate microspheres: Dissolve sodium alginate in distilled water to prepare a sodium alginate solution with a concentration of 2% w / v, in a mass ratio of 1:0.2×10 -5 Add PDGF-BB, stir well to make water phase; measure a certain volume of olive oil, add Tween 80 at a ratio of 1% v / v, and stir at 750 rpm for 1 h to prepare an organic phase; measure 100 mL of organic phase, stir at 700 rpm Add 20 mL of aqueous phase, stir at 750 rpm for 1 h, add 40 mL of calcium chloride solution with a concentration of 1% w / v, stir at 500 rpm for 1 h, then add 10 mL of isoacetone, stir at 400 rpm for 30 min, the mixture is centrifuged at 6000 rpm for 10 min, and the obtained precipitates were separated by isoacetone. Acetone and distilled water were alternately washed twice, and freeze-dried to obtain PDGF-BB@calcium alginate microspheres.

[0087] (2) Preparation of calcium alginate microspheres: the preparation method is the same as (1), except that ...

Embodiment 3

[0096] (1) Preparation of PDGF-BB@calcium alginate microspheres: Dissolve sodium alginate in distilled water to prepare a sodium alginate solution with a concentration of 2% w / v, in a mass ratio of 1:0.1×10 -5 Add PDGF-BB, stir well to make water phase; measure a certain volume of olive oil, add Tween 80 at a ratio of 1% v / v, and stir at 700 rpm for 1.5 h to prepare an organic phase; measure 100 mL of organic phase, stir at 700 rpm Add 20 mL of aqueous phase, stir at 750 rpm for 1 h, add 40 mL of calcium chloride solution with a concentration of 1% w / v, stir at 500 rpm for 1 h, then add 10 mL of isoacetone, stir at 400 rpm for 30 min, and centrifuge the mixture at 6000 rpm for 8 min. Isoacetone and distilled water were alternately washed three times, and freeze-dried to obtain PDGF-BB@calcium alginate microspheres.

[0097] (2) Preparation of calcium alginate microspheres: the preparation method is the same as (1), except that PDGF-BB is not added.

[0098] (3) Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com