Method for preparing composite conductive filler by using fine coal gasification slag and prepared filler

A composite conductive and coal gasification technology, which is used in the preparation of composite conductive fillers and in the field of composite conductive fillers, can solve the problems of the mechanical properties of polymer materials, the peeling of composite materials, and the irregular shape of powder, and achieve stable physical and chemical properties. The effect of firm coverage and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

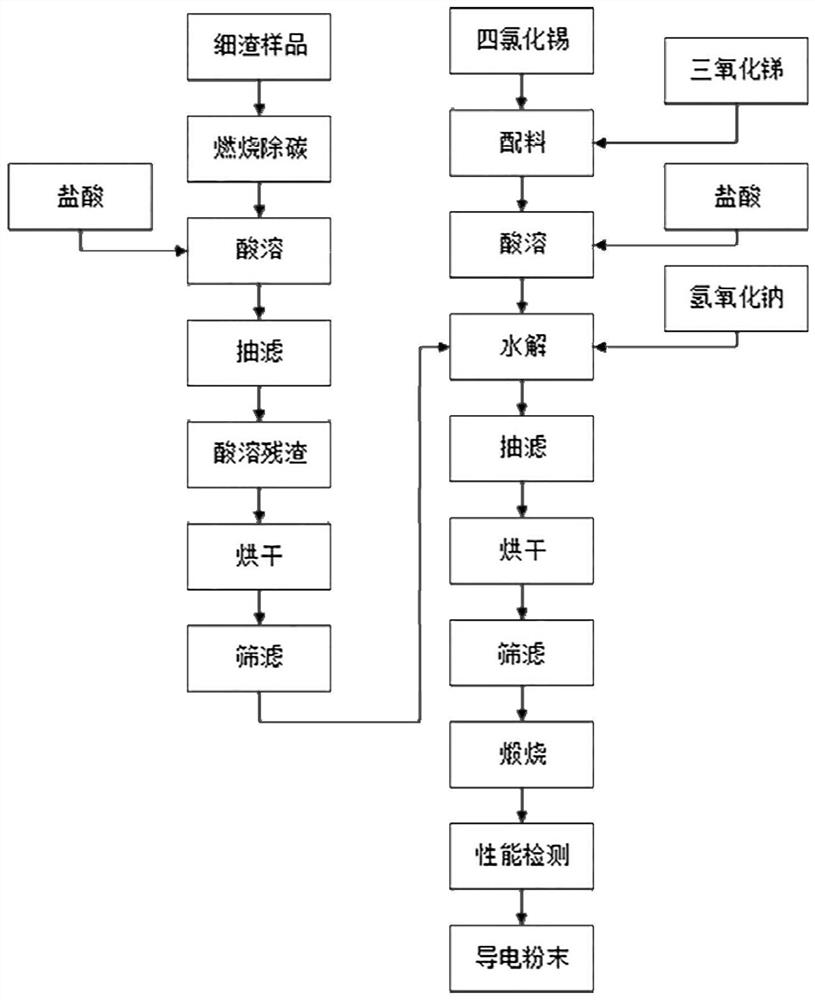

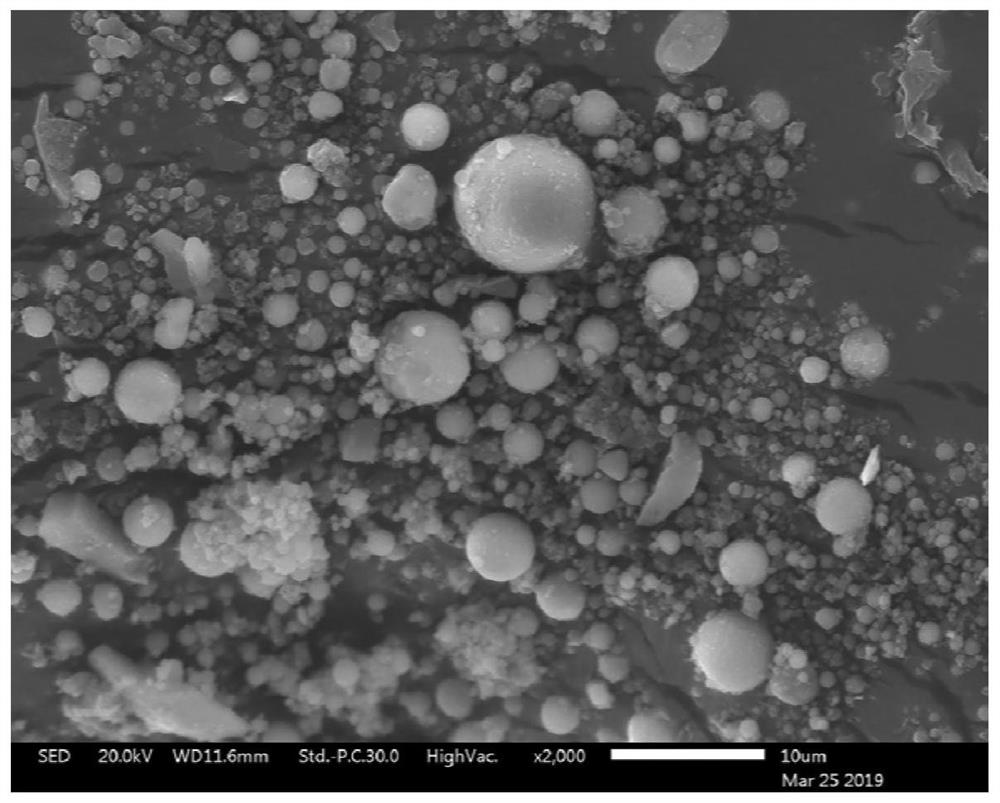

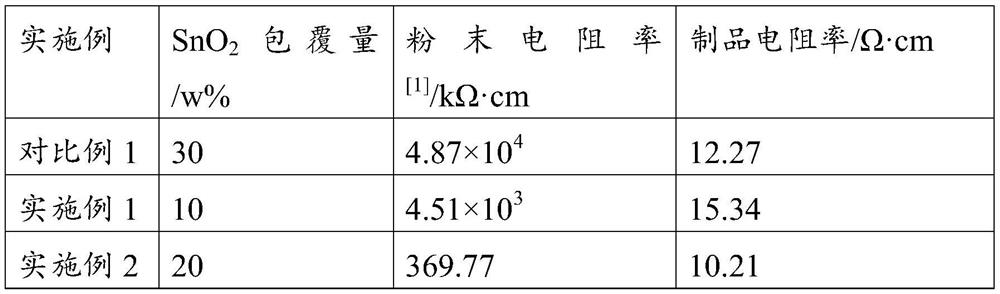

[0040] 1. Take 500 grams of dried coal gasification fine slag, and after calcination at 700°C for 3 hours in a muffle furnace to remove carbon, dissolve it in 15% hydrochloric acid solution at a solid-to-liquid ratio (g / ml) of 1:5 Leach in medium acid for 5 hours, then filter with suction, wash and dry, pass through a 200-mesh standard sieve, and the silicon-aluminum microbead powder under the sieve is ready for use. The specific surface area of the powder is 76.41m 2 / g, a large number of pores appear in the microbeads, and the powder density becomes smaller.

[0041] 2. Take 5 g of the sieved silica-alumina glass microbead powder and place it in 100 ml of distilled water, stir in a water bath at 30°C to form a suspension, and slowly add the doped SbCl 3 0.1mol / L of SnCl 4 4H 2 9 ml of multi-ion hydrochloric acid mixed solution of O (the molar ratio of Sn / Sb is 5:1), and at the same time, dropwise add 20% NaOH solution to keep the pH of the solution in the range of 1-1.5,...

Embodiment 2

[0045] 1. Take 500 grams of dried coal gasification fine slag, and after calcination at 700°C for 3 hours in a muffle furnace to remove carbon, dissolve it in 20% hydrochloric acid solution at a solid-to-liquid ratio (g / ml) of 1:4 Leach in medium acid for 4 hours, then filter with suction, wash and dry, pass through a 200-mesh standard sieve, and the silica-alumina microbead powder under the sieve is ready for use. The specific surface area of the powder is 119.52m 2 / g, the number of pores in the microbeads increases continuously.

[0046] 2. Take 5 g of the sieved silica-alumina glass microbead powder and place it in 100 ml of distilled water, stir in a water bath at 50°C to form a suspension, and slowly add the doped SbCl 3 0.1mol / L of SnCl 4 4H 2 O hydrochloric acid multi-ion mixed solution 18ml (the molar ratio of Sn / Sb is 8: 1), while adding 20% NaOH solution dropwise to keep the pH of the solution in the range of 2-2.5, stir for 2.5h after the titration is complet...

Embodiment 3

[0050] 1. Take 500 grams of dried coal gasification fine slag, and after calcination at 700°C for 3 hours in a muffle furnace to remove carbon, dissolve it in 30% hydrochloric acid solution at a solid-to-liquid ratio (g / ml) of 1:4 Leach in medium acid for 4 hours, then suction filter, wash and dry, pass through a 200-mesh standard sieve, and the silicon-aluminum microbead powder under the sieve is ready for use. The specific surface area of the powder is 158.57m 2 / g, the porosity reaches the maximum, the powder is loose and easy to fly out, and the density drops obviously.

[0051] 2. Take 5 g of the sieved silica-alumina glass microbead powder and place it in 100 ml of distilled water, stir in a water bath at 80°C to form a suspension, and slowly add the doped SbCl 3 0.1mol / L of SnCl 4 4H 2 O hydrochloric acid multi-ion mixed solution 22.5ml (the molar ratio of Sn / Sb is 7:1), while adding dropwise 20% NaOH solution to keep the pH of the solution in the range of 1-1.5, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com