Material with low humidity sensitivity and high saturation water absorption and preparation method thereof

A sensitivity and water absorption technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of adsorption loss, limitation, low saturated water absorption of molecular sieve materials, etc., and achieve the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Hydroxy-terminated polysiloxane preparation

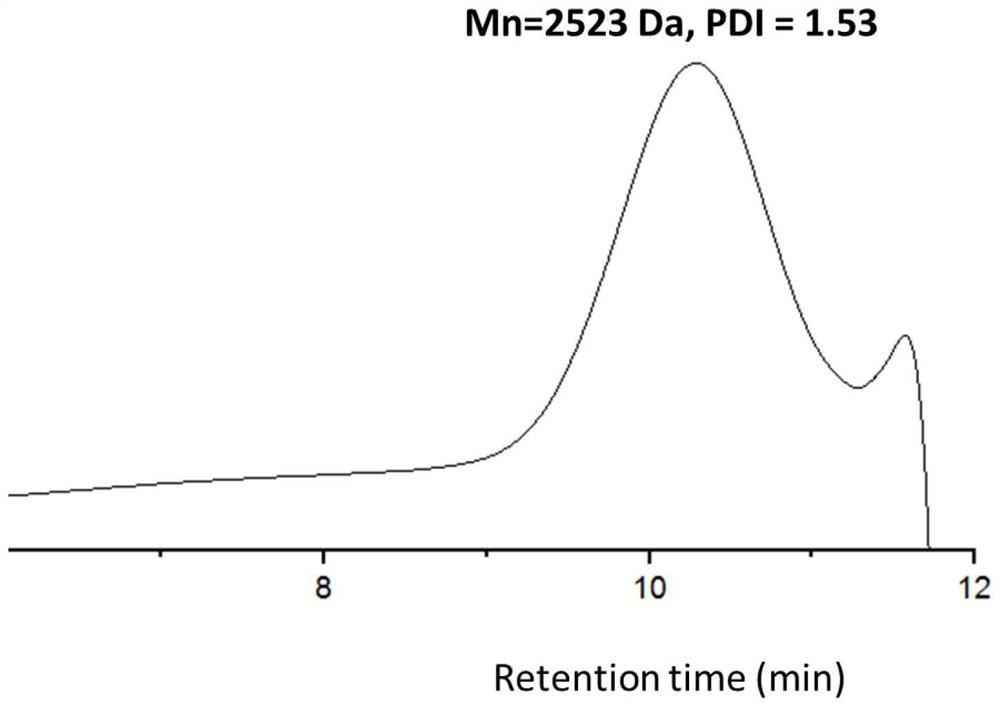

[0054] Measure 50ml of dimethyldichlorosilane into a 500ml round-bottomed flask, add 150ml of ether, stir, cool in an ice bath to 4°C, add 50ml of 1M hydrochloric acid solution dropwise into the flask while stirring, and continue the reaction for 2 hours after the addition is complete. Then let it stand for layering. The organic layer was washed successively with saturated sodium bicarbonate and deionized water, and then dried with anhydrous sodium sulfate, diethyl ether was distilled off under reduced pressure to obtain a colorless transparent clear liquid. Adopt the method test of Gel Permeation Chromatography, monodisperse PDMS is that standard product is calculated and shows that the molecular weight of product is about 2.5KDa (chromatogram such as figure 1 shown).

[0055] Absorbent material preparation

[0056] Weigh 1.0 g of hydroxyl-terminated polydimethylsiloxane (M n ~2.5KDa) in a 100ml beaker, add 20ml of ethy...

Embodiment 2

[0061] Weigh 1.0g of p-1,4-bis(hydroxydimethylsilyl)benzene into a 100ml beaker, add 20ml of ethyl acetate to dissolve to obtain an ethyl acetate solution; take another beaker, weigh 12g of 400 mesh Diboron trioxide, slowly add the ethyl acetate solution into diboron trioxide under stirring, keep the reaction temperature of the system at 100°C, after the reaction is finished, volatilize the ethyl acetate and dehydrate under vacuum at 120°C to obtain The white powder has a water absorption of 63.2wt% when placed at room temperature at a relative humidity of 68% for 3 hours; and a water absorption of 64.5% after being placed at room temperature at a relative humidity of 4% for two months.

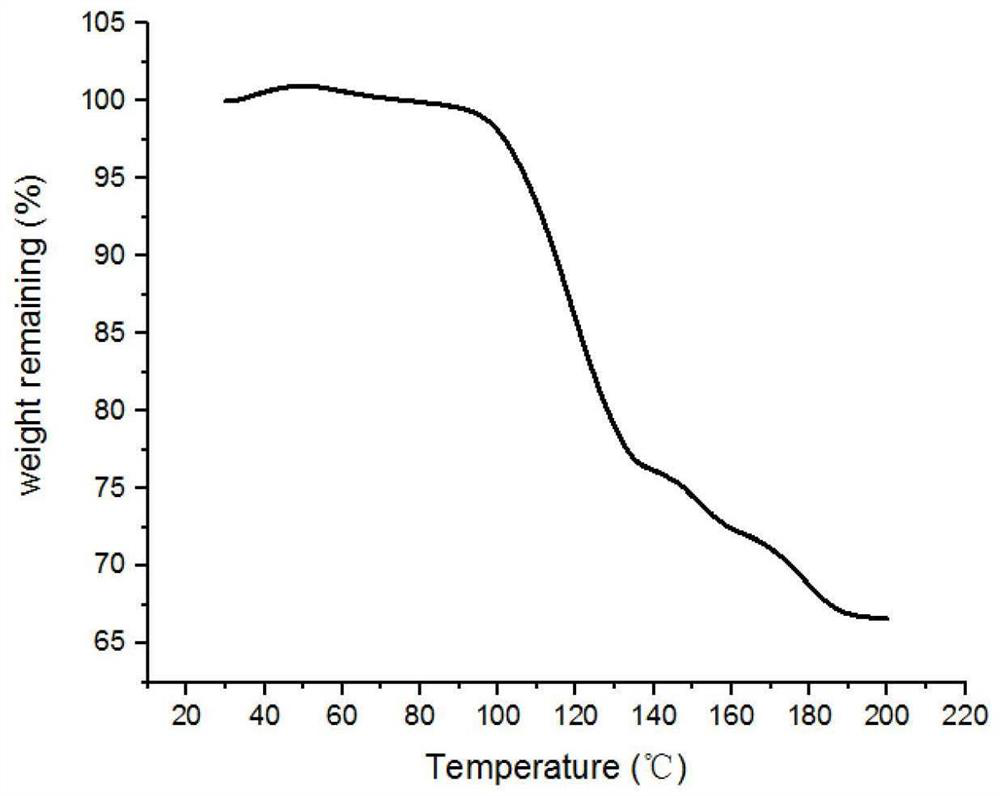

[0062] The thermogravimetric loss of the saturated sample in a nitrogen atmosphere shows that the weight loss temperature of the sample is greater than 80°C (such as Figure 4 shown).

Embodiment 3

[0064] Take by weighing 1.0g hydroxyl end-capped MQ resin (hydroxyl content 5wt%), add in the 250ml ball mill jar, then add 21g boric acid in the ball mill jar, and ball mill 24h, keep system reaction temperature at 160 ℃, after the completion of the reaction, put The product was passed through a 200-mesh sieve and dehydrated under vacuum. The water absorption of the obtained white solid was 62.2wt% when placed at room temperature for 3 hours at a relative humidity of 68%, and 61.8% after being placed at room temperature for two months at a relative humidity of 4%.

[0065] The thermogravimetric loss of the saturated sample in a nitrogen atmosphere shows that the weight loss temperature of the sample is greater than 80°C (such as Figure 5 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

| Saturated water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com