High-purity water-soluble silicon wafer cleaning agent and preparation method thereof

A silicon wafer cleaning agent, water-soluble technology, applied in the direction of surface-active detergent composition, detergent compounding agent, detergent composition, etc., can solve the problems of reduced yield and silicon wafer pits, etc., to prevent corrosion, The safety is guaranteed and the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

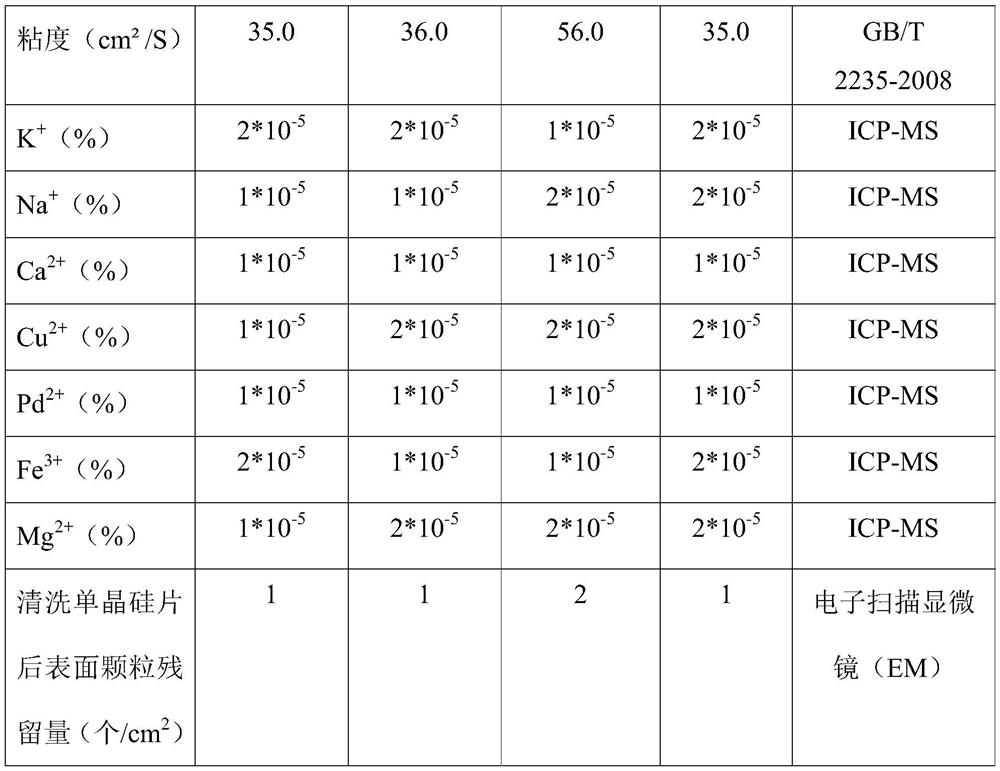

Embodiment 1

[0022] Start stirring, respectively pump 140kg of fatty alcohol polyoxyethylene ether ammonium sulfate (AESA), 160kg of acrylic acid copolymer and 60kg of PEG-400 into a 2000L stainless steel reaction kettle with a vacuum pump, open the steam valve and heat at 40-60°C, and wait for the pumped raw materials After complete melting, stop heating, then add 700kg of conductive water with a resistivity of 1M, perform ion exchange after stirring fully, and store the ion-exchanged liquid in a 2000-liter plastic storage tank. Sampling analysis. The density, PH, viscosity, metal impurities and other indicators of the finished product are all within the control index range. After the analysis is qualified, 500kg of 35% formaldehyde is added, and then filtered with a 0.5μm filter membrane, and the finished product is sampled again for analysis, and 25kg / barrel is filled.

Embodiment 2

[0024] Start stirring, respectively pump 80kg fatty alcohol polyoxyethylene ether sodium sulfate, 120kg acrylamide polymer and 30kg PEG-600 into a 2000L stainless steel reaction kettle with a vacuum pump, open the steam valve and heat at 40-60°C until the pumped raw materials are completely melted Finally, stop heating, then add 470kg of conductive water with a resistivity of 1.5M, and perform ion exchange after stirring fully. The liquid after ion exchange is stored in a 2000-liter plastic storage tank. Sampling analysis. The density, PH, viscosity, metal impurities and other indicators of the finished product are all within the control index range. After the analysis is qualified, 300kg of 35% formaldehyde is added, and then filtered with a 0.5μm filter membrane, and the finished product is sampled again for analysis, and 25kg / barrel is filled.

Embodiment 3

[0026] Start stirring, respectively pump 50kg of nonylphenol polyoxyethylene ether (TX-10), 150kg of vinyl alcohol polymer and 50kg of PEG-200 into a 2000L stainless steel reaction kettle with a vacuum pump, open the steam valve and heat at 40-60°C, etc. After the raw materials are completely melted, stop heating, then add 450kg of conductive water with a resistivity of 1.5M, stir well and perform ion exchange, and store the ion-exchanged liquid in a 2000-liter plastic storage tank. Sampling analysis. The density, PH, viscosity, metal impurities and other indicators of the finished product are all within the control index range. After the analysis is qualified, 300kg of 35% formaldehyde is added, and then filtered with a 0.5μm filter membrane, and the finished product is sampled again for analysis, and 25kg / barrel is filled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com