A High Brightness Main Oscillation Power Amplified Picosecond Laser System

A power amplification and picosecond laser technology, which is applied to lasers, laser devices, laser components, etc., can solve the problems that crystals cannot withstand high power, end-pump pumping power density is high, and multi-stage amplifier structures are required to achieve Effects of improved beam quality, simplified structure, easy integration and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

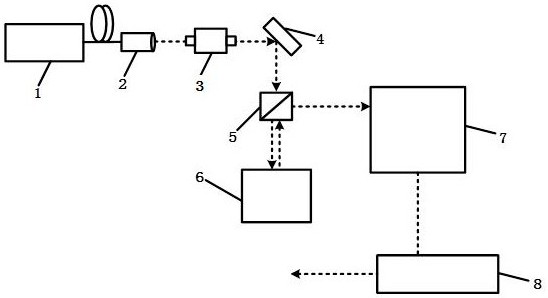

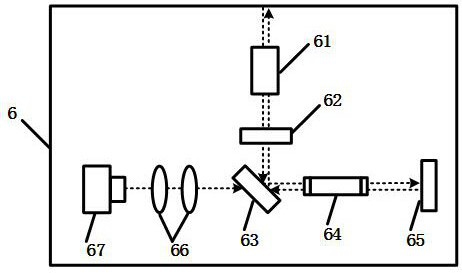

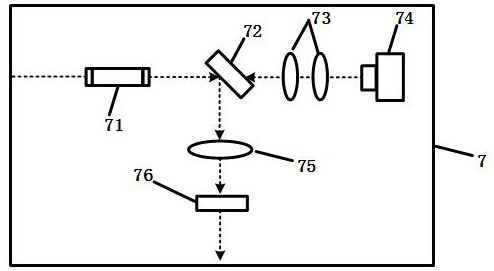

[0038] The invention provides a high-brightness main oscillation power amplifying picosecond laser system, such as figure 1 As shown, it includes an all-polarization-maintaining fiber picosecond seed laser 1, a fiber collimator 2, a space isolator 3, a 45° total reflection mirror 4, a polarization beam splitter prism 5 (PBS), a first-class solid Traveling wave amplifier 6, two-stage solid-state traveling wave amplifier 7 and three-stage solid-state traveling-wave amplifier 8, one-stage solid-state traveling wave amplifier 6 is located on the transmitted light side of polarization beam splitter prism 5, and two-level solid-state traveling wave amplifier 7 is located at polarization beam splitter prism 5 the reflected light side.

[0039] All polarization-maintaining fiber picosecond seed laser 1, for generating picosecond pulsed laser at 1064 nm wavelength, pulse width 100 nJ, repetition rate adjustment range 10 kHz-20 MHz.

[0040] The fiber collimator 2 pigtail is connected...

Embodiment 2

[0070] The invention also provides a high-brightness main oscillation power amplifying picosecond laser system, such as Figure 5 As shown, on the basis of the structure of Embodiment 1, a frequency multiplication module 9 is also set after the three-stage solid-state traveling wave amplifier 8 . like Image 6 As shown, the frequency doubling module 9 includes a second lens 91, a frequency doubling crystal 921, a third lens 93, a fourth 45° dichroic mirror 94 and a A laser absorber 95 is arranged on the side, and the frequency-doubling crystal 921 is wrapped with an indium foil with a thickness of 0.05 mm and placed in a fixture 922 to ensure close contact. The material of the fixture 922 can be selected from red copper. The fixture 922 is connected to the temperature control module 923 . The temperature control module 923 can use a semiconductor refrigerator (Thermo Electric Cooler, TEC), and mainly changes the temperature of the fixture 922, so as to precisely control the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| optical damage threshold | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com