Method for preparing nano copper powder by taking copper oxide as raw material

A technology of nano-copper powder and copper oxide, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. It can solve the problems of high energy consumption and large particle size of copper powder, and achieve low energy consumption and low volatility. The effect of small degree and saving additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing nano-copper powder with copper oxide as raw material, comprising the steps of:

[0023] S1. Choline chloride and glycerol were prepared in a molar ratio of 1:2 at 80°C to form a colorless and transparent deep eutectic ionic liquid. Add 0.3 g of copper oxide powder into 50 mL of the eutectic ionic liquid at 100° C., stir and dissolve to obtain a bright yellow solution A. Add 1.5 g of ascorbic acid into solution A, stir and dissolve to obtain solution B. Add 1.6g of potassium hydroxide into solution B, stir and dissolve to obtain solution C.

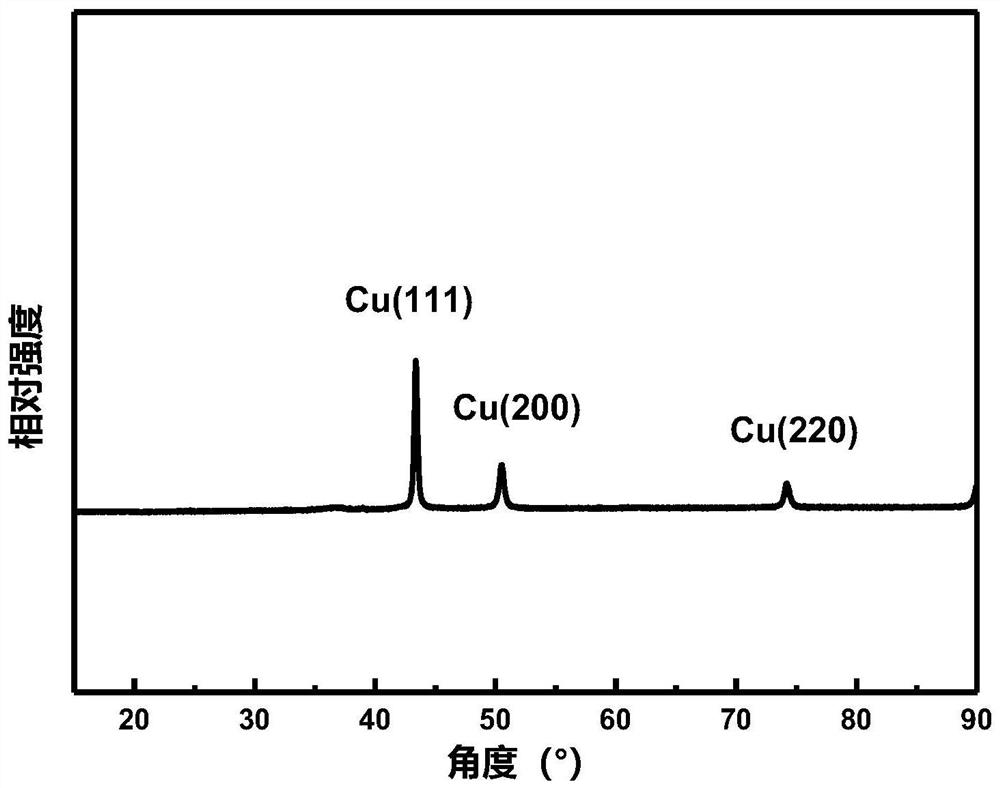

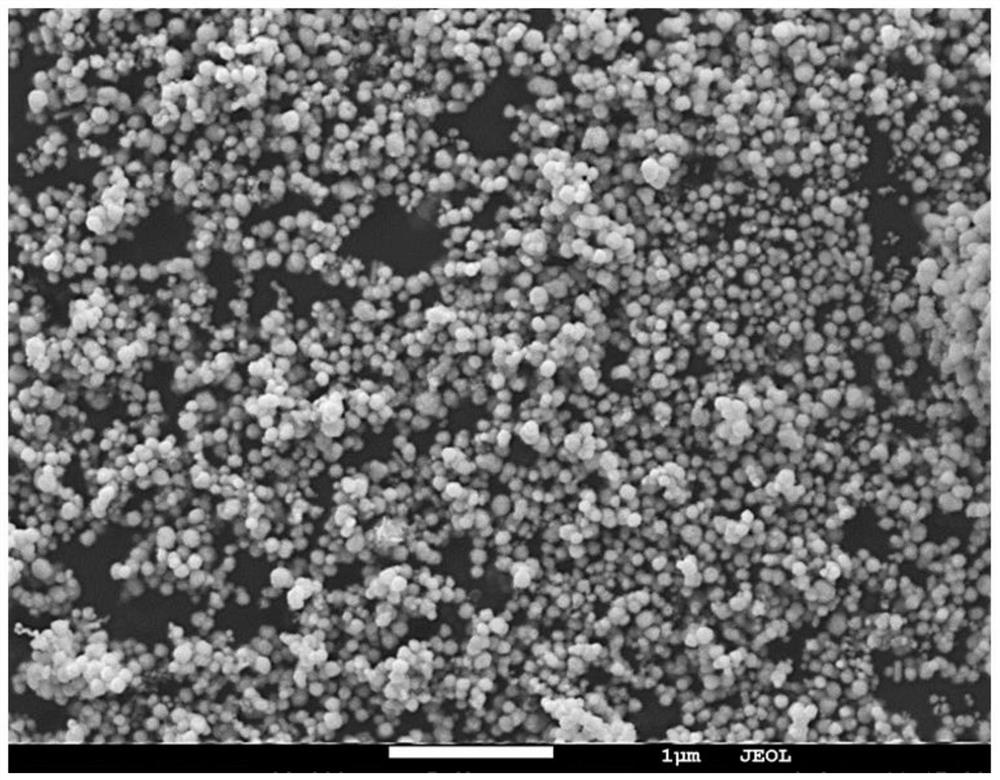

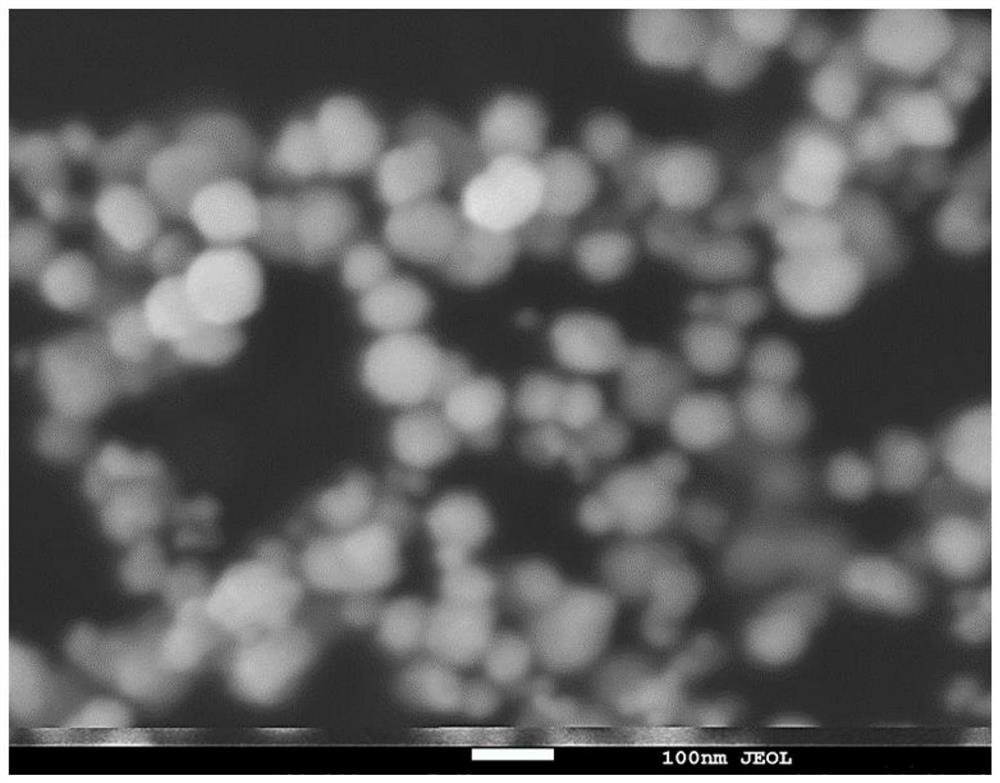

[0024] S2. Put solution C in a reaction vessel at 100° C. for solvothermal reaction for 12 hours. The product copper powder was separated under a nitrogen atmosphere, and the product was washed four times with absolute ethanol and ultrapure water, and the washed copper powder was vacuum-dried, and sealed with nitrogen gas for storage. The nano-copper powder prepared in this embodiment is subjected to X-ray ...

Embodiment 2

[0026] A method for preparing nano-copper powder with copper oxide as raw material, comprising the steps of:

[0027] S1. Choline chloride and glycerol were prepared at a molar ratio of 1:2 at a temperature of 90°C to form a colorless and transparent deep eutectic ionic liquid. Add 0.5 g of copper oxide powder into 100 mL of the eutectic ionic liquid at 105° C., stir and dissolve to obtain a bright yellow solution A. Add 3.0 g of ascorbic acid into solution A, stir and dissolve to obtain solution B. Add 3.0 g of potassium hydroxide into solution B, stir and dissolve to obtain solution C.

[0028] S2. Put solution C in a reaction vessel at 105° C. for solvothermal reaction for 8 hours. The product copper powder was separated under a nitrogen atmosphere, and the product was washed five times with absolute ethanol and ultrapure water respectively, and the washed copper powder was vacuum-dried, and sealed with nitrogen gas for preservation. After testing, the purity of the nano...

Embodiment 3

[0030] A method for preparing nano-copper powder with copper oxide as raw material, comprising the steps of:

[0031] S1. Choline chloride and glycerol were prepared at a molar ratio of 1:3 at a temperature of 85°C to form a colorless and transparent deep eutectic ionic liquid. Add 0.2 g of copper oxide powder into 100 mL of the eutectic ionic liquid at 90° C., stir and dissolve to obtain a bright yellow solution A. Add 1.0 g of sodium ascorbate into solution A, stir and dissolve to obtain solution B. Add 0.3g of sodium hydroxide into solution B, stir and dissolve to obtain solution C.

[0032] S2. Put solution C in a reaction vessel at 110° C. for solvothermal reaction for 8 hours. The product copper powder was separated under a nitrogen atmosphere, and the product was washed four times with absolute ethanol and ultrapure water, and the washed copper powder was vacuum-dried, and sealed with nitrogen gas for storage. After testing, the purity of the nano-copper powder prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com