Zinc-porphyrin complex as well as preparation method and application thereof

A technology of porphyrin complexes and porphyrins, applied in the direction of organic chemistry, can solve the problems of poor thermal stability of additives, reduce the service life of materials, affect mechanical properties, etc., and achieve improved mechanical properties, inhibit heat release, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Dissolve 5g of p-bromobenzaldehyde in 300mL of propionic acid and propionic anhydride mixed solvent (the molar ratio of propionic acid and propionic anhydride is 3:1) at room temperature, stir and accelerate the dissolution for 30min under nitrogen atmosphere until completely dissolved.

[0036] 2) Take the solution in step 1) and transfer it to an oil bath at 150°C. After preheating for a period of time, slowly add the mixed solution of 10mL propionic acid and 2g pyrrole dropwise while stirring. Reaction 3h.

[0037] 3) Add pure water to the solution that has completed the reaction in step 2) for precipitation, then filter the resulting product to remove the precipitate and wash to remove the solvent completely, and the dark purple powder obtained after purification and drying is porphyrin crystal BrTPP (yield: 15% ).

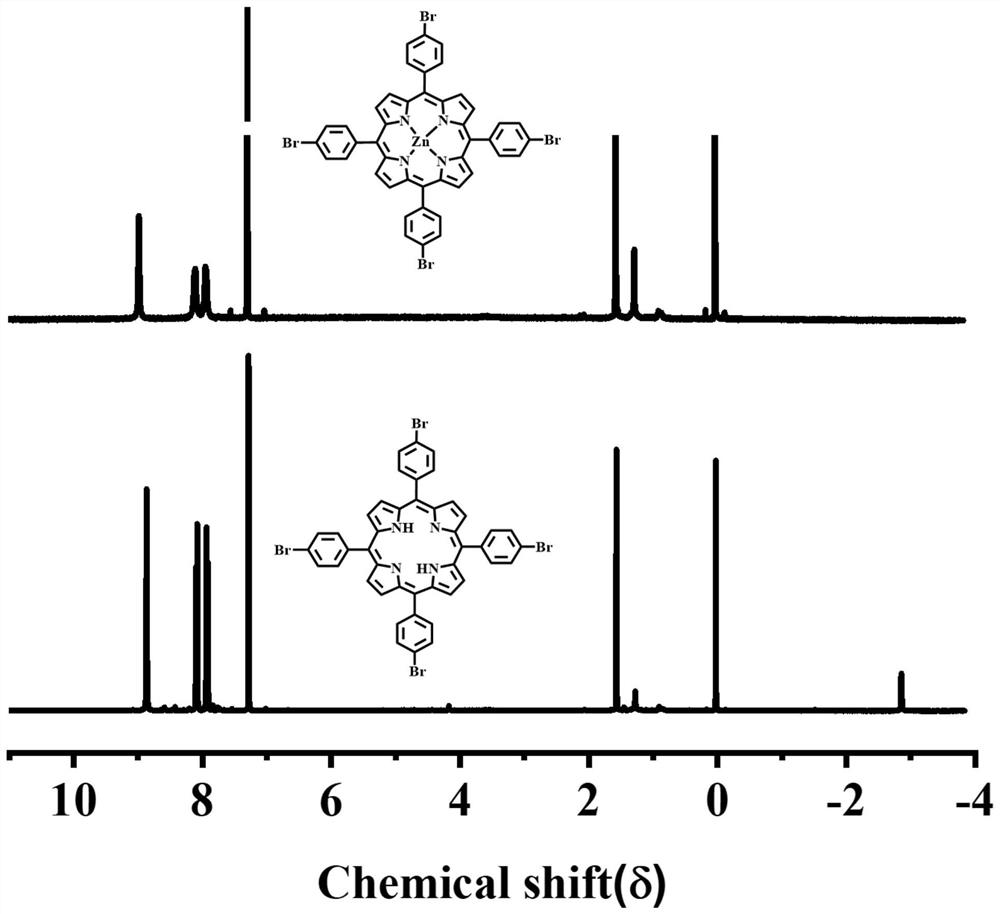

[0038] figure 1 H NMR spectrum of mesoporphyrin 1 H NMR (400MHz, deuterated chloroform) specific analysis is as follows (δ, ppm): the chemical sh...

Embodiment 2

[0040] 1) Dissolve 5g of p-bromobenzaldehyde in 300mL of propionic acid and propionic anhydride mixed solvent (the molar ratio of propionic acid and propionic anhydride is 2.8:1) at room temperature, stir and accelerate the dissolution under nitrogen atmosphere for 35min until completely dissolved.

[0041] 2) Take the solution in step 1) and transfer it to a 140°C oil bath. After preheating for a period of time, slowly add a mixed solution of 10mL propionic acid and 2.2g pyrrole dropwise while stirring. Continue to react for 3.5h.

[0042] 3) Add pure water to the solution that has completed the reaction in step 2) for precipitation, then filter the product obtained to remove the precipitate and wash to completely remove the solvent, and the dark purple powder obtained after purification and drying is the porphyrin crystal BrTPP (yield: 16 %).

Embodiment 3

[0044]1) Dissolve 5g of p-bromobenzaldehyde in 300mL of propionic acid and propionic anhydride mixed solvent (the molar ratio of propionic acid and propionic anhydride is 3.2:1) at room temperature, stir and accelerate the dissolution for 40min under nitrogen atmosphere until completely dissolved.

[0045] 2) Take the solution in step 1) and transfer it to a 160°C oil bath. After preheating for a period of time, slowly add a mixed solution of 10mL propionic acid and 1.92g pyrrole dropwise while stirring. Continue to react for 4h.

[0046] 3) Add pure water to the solution that has completed the reaction in step 2) for precipitation, then filter the resulting product to remove the precipitate and wash to completely remove the solvent, and the dark purple powder obtained after purification and drying is the porphyrin crystal BrTPP (yield: 20 %).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com