Self-supporting electrode, preparation method thereof and lithium-sulfur battery

A self-supporting electrode and lithium-sulfur battery technology, applied in lithium batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve the problems of battery energy density and power density decrease, battery energy density decrease, electrode preparation cost increase, etc., to achieve Effects of increasing surface load, improving electrical conductivity, improving sulfur utilization and electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a self-supporting electrode, a preparation method thereof and a lithium-sulfur battery. A kind of preparation method of self-supporting electrode comprises the following steps:

[0039] S1: Pretreat flake biomass, the specific pretreatment process includes cutting, acid leaching, boiling and drying. The function of pretreatment is mainly to cut the irregular biomass raw materials into discs, and remove impurity molecules in the biomass materials by acid leaching and boiling.

[0040] Wherein, the biomass is one or more sheet-like biomass containing lignin, cellulose, hemicellulose, polysaccharide, polyalcohol or seaweed.

[0041] S2: The transition metal-containing microwave absorber and the conductive modifier are loaded on the surface of the sheet-shaped biomass pretreated in step S1, and the way of impregnation loading can be adopted.

[0042] The transition metal-containing microwave absorber is at least one of soluble salts of cobalt, zinc,...

Embodiment 1

[0055] A method for preparing a self-supporting electrode, comprising the following steps:

[0056] The pomelo peel slices were cut into discs with a thickness of 1 cm and a diameter of 16 mm. After acid leaching, boiling, and drying, 500 g of dried pomelo peel slices were added to a mixture containing 5 g of graphene and 10 g of microwave adsorbent Ni(NO 3 ) 2 N was introduced into the homogeneous solution of 2 protection, and then put it into a microwave digestion apparatus, and apply a uniform magnetic field of 200mT to carry out microwave reaction. The power and frequency of the microwave are 1kW and 2450Mkz respectively, and the temperature control mode is used to set the reaction temperature to 300°C, and the pyrolysis takes 30 minutes, so that the impurities in the grapefruit peel are completely decomposed, and the graphene and Ni ions are uniformly loaded on the carbon substrate and modification; turn off the microwave, and after the reactor is cooled to room tempera...

Embodiment 2

[0058] A method for preparing a self-supporting electrode, comprising the following steps:

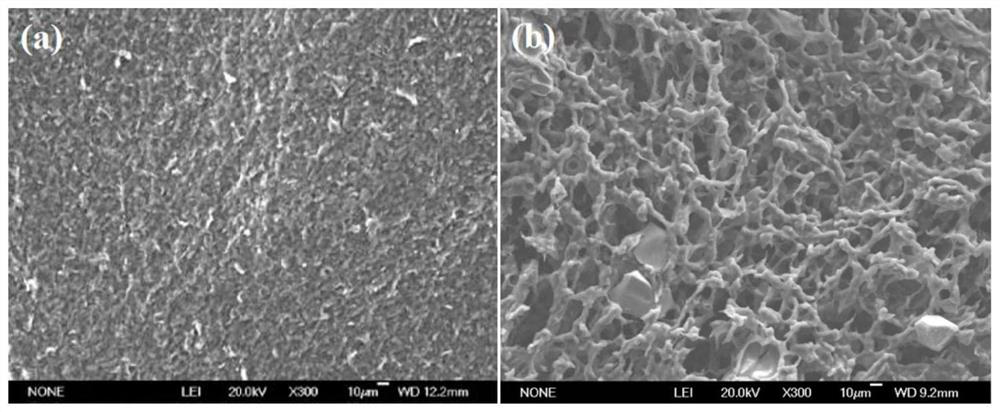

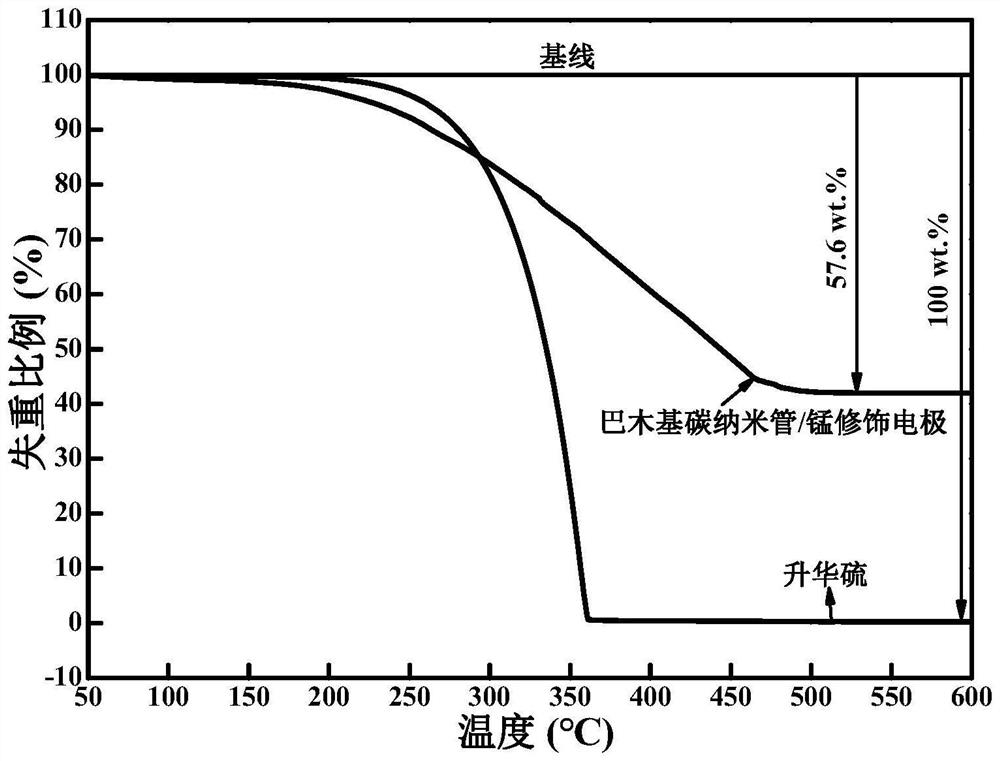

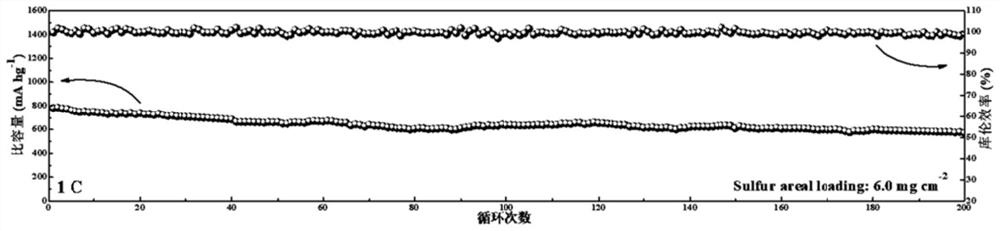

[0059] Cut the Bamu chips into discs with a thickness of 1cm and a diameter of 16mm, pickle, boil, and dry, and add 500g of dried Bamu chips to a uniform solution containing 50g graphene and 5g microwave adsorbent manganese chloride Ar protection was passed through the medium, and then put into a microwave digestion apparatus, and a uniform magnetic field of 200mT was applied to carry out microwave reaction. The power and frequency of the microwave are 2kW and 915Mkz respectively, and the temperature control mode is used to set the reaction temperature at 200°C, and the pyrolysis takes 10 minutes to completely decompose the impurities in the Bamu chips, so that the graphene and Mn ions are evenly loaded on the carbon matrix and modification; turn off the microwave, and after the reactor is cooled to room temperature, take out the reactor, wash and dry, and carry out chemical sulfur loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com