Nitrogen-doped PHCS-Zn2In2S5 composite photocatalyst as well as preparation method and application thereof

A phcs-zn2in2s5, composite light technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Good antibacterial properties, stable performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A nitrogen-doped PHCS-Zn 2 In 2 S 5 The preparation method of composite photocatalyst, concrete steps are as follows:

[0039] (1) Dissolve 2 mmol of zinc sulfate heptahydrate and 2 mmol of indium chloride hexahydrate in 50 mL of a mixed solvent, and stir until the solution is clear to obtain solution A. The mixed solvent is 30 mL of deionized water and 20 mL of glycerin Alcohol mixed solvent;

[0040] (2) Weigh sodium lauryl sulfate (0.006 g), glucose (0.288 g), and melamine (0.009 g), and dissolve them in 10 mL of deionized water in turn, and stir until uniform to obtain solution B;

[0041] (3) Add solution B in step (2) to solution A in step (1), then add 10 mmol thioacetamide (TAA), keep stirring for 2 h, then transfer to 100 mL polytetrafluoroethylene for high pressure reaction In the kettle, hydrothermal reaction was carried out at 160 °C for 12 h. After the reaction, it was naturally cooled to room temperature and centrifuged to obtain a yellow precipitate. ...

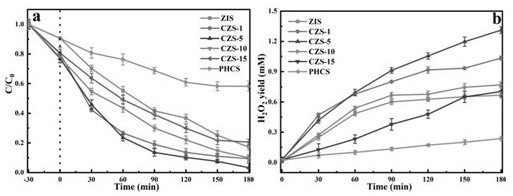

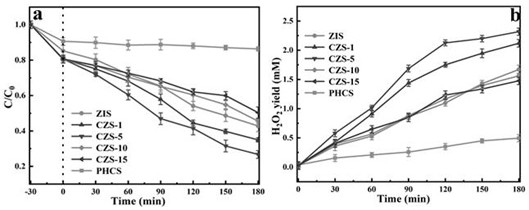

Embodiment 2

[0043] Nitrogen-doped PHCS-Zn in embodiment 2 2 In 2 S 5 The difference between the preparation method of the composite photocatalyst and Example 1 is that by changing the amount of glucose in step (2), the hollow glucose microspheres PHCS and the ternary sulfide Zn 2 In 2 S 5 The mass ratio of glucose was 0.0576 g, and the obtained product was denoted as CZS-1.

[0044] In step (3), the hydrothermal reaction temperature is 150° C., and the reaction time is 18 hours.

Embodiment 3

[0046] Nitrogen-doped PHCS-Zn in embodiment 3 2 In 2 S 5 The difference between the preparation method of the composite photocatalyst and Example 1 is that the dosage of glucose in step (2) is 0.576 g, and the obtained product is denoted as CZS-10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com