High-nickel sodium ion positive electrode material, preparation method thereof and battery

A cathode material, sodium ion technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as limiting the potential application of sodium ion cathode materials, increasing the interface impedance between the material and the electrolyte, and reducing the rate of sodium ion diffusion. , to improve the electrochemical performance, good cycle stability, and enhance the effect of Na+ transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

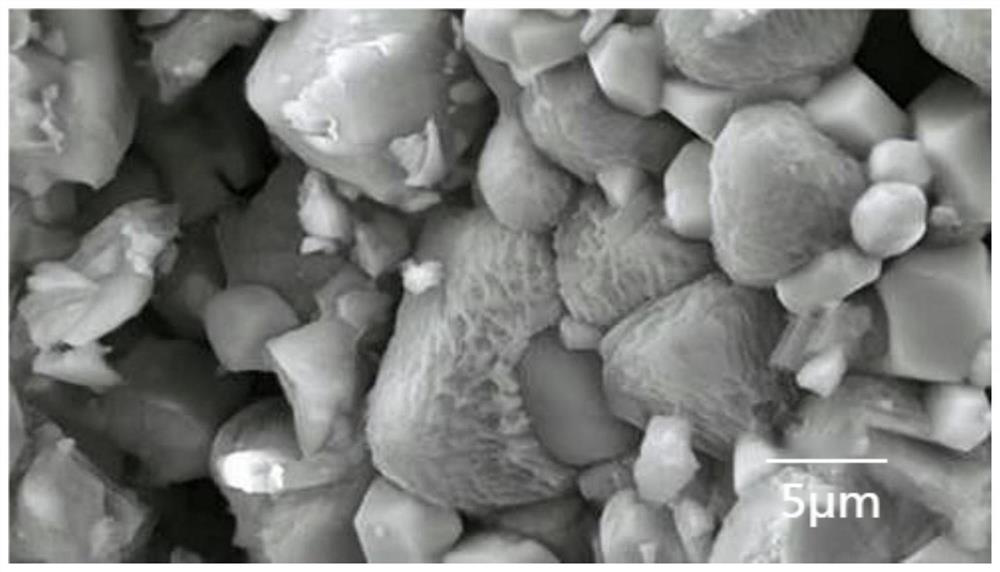

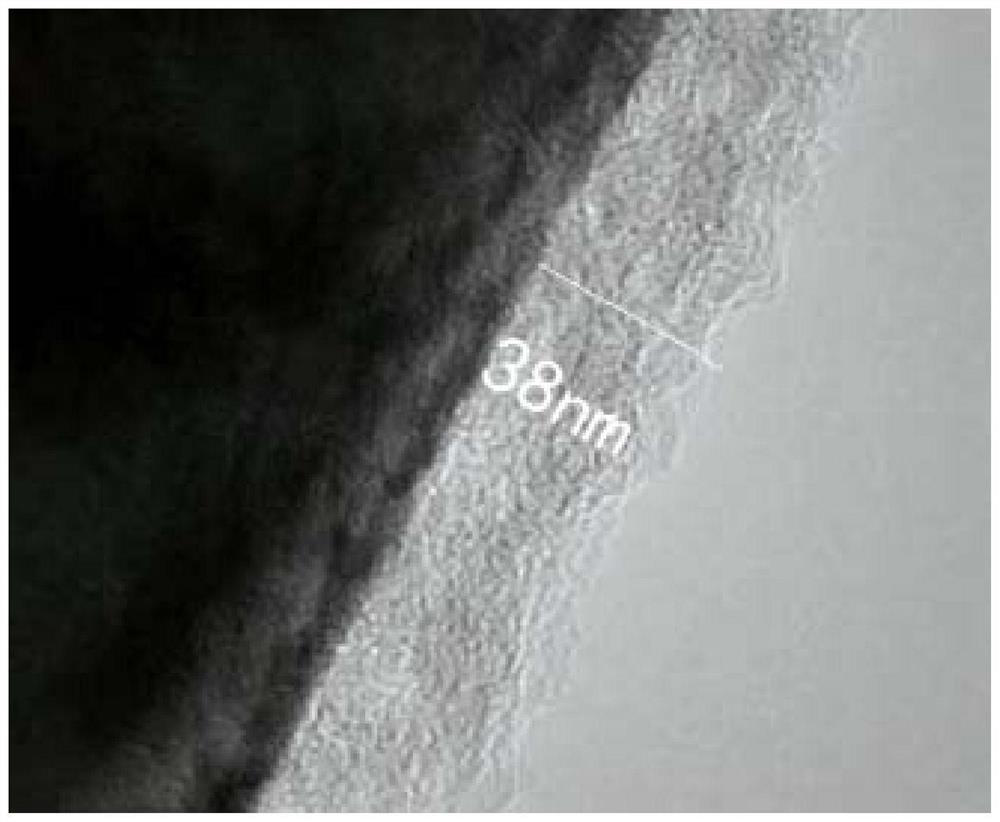

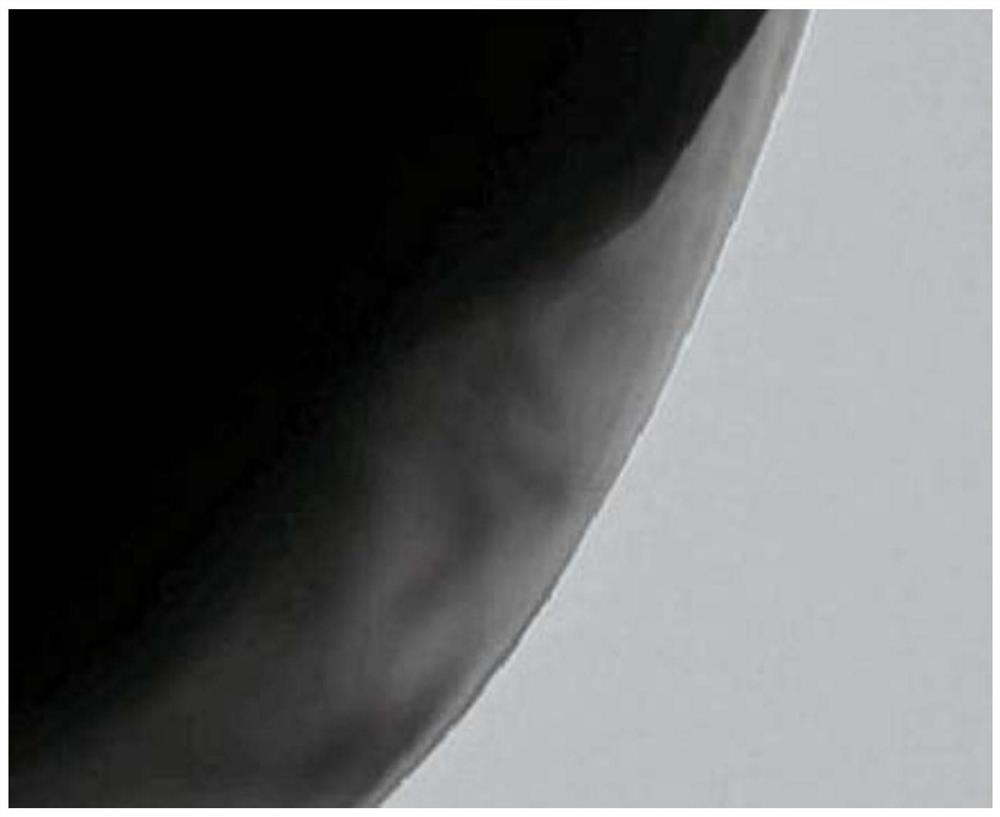

[0042] A kind of high nickel sodium ion cathode material, its chemical formula is NaNi 0.8 C o0.1 mn 0.1 o 2 ·0.059CNP-Al / 0.03NH 4 VO 3 .

[0043] The preparation method of the above-mentioned high-nickel sodium ion positive electrode material comprises the following steps:

[0044] (1) Preparation of nickel-cobalt-manganese materials: the ternary positive electrode material recovered from waste ternary lithium batteries is subjected to acid leaching, aluminum removal, copper removal, and extraction to obtain nickel-cobalt-manganese sulfate mixed salt solution, and nickel-cobalt-manganese sulfate mixed salt solution is determined Medium nickel-cobalt-manganese molar ratio (0.965:0.12:0.11), take 500mL in a beaker, add 0.011M nickel sulfate, 0.002M cobalt sulfate, 0.012M manganese sulfate to the nickel sulfate mixed salt solution, add 40ml Base cellulose, stir well, keep the temperature at 45°C, add sodium carbonate, stir until complete precipitation, and let it stand for...

Embodiment 2

[0057] A kind of high nickel sodium ion cathode material, its chemical formula is NaNi 0.74 co 0.16 mn 0.1 o 2 ·0.045CNP-Al / 0.02NH 4 VO 3 .

[0058] The preparation method of the above-mentioned high-nickel sodium ion positive electrode material comprises the following steps:

[0059] (1) Preparation of nickel-cobalt-manganese materials: the ternary positive electrode material recovered from waste ternary lithium batteries is subjected to acid leaching, aluminum removal, copper removal, and extraction to obtain nickel-cobalt-manganese sulfate mixed salt solution, and nickel-cobalt-manganese sulfate mixed salt solution is determined In the nickel-cobalt-manganese molar ratio (0.965:0.12:0.11), take 500mL and put it in a beaker, add 0.09M cobalt sulfate and 0.02M manganese sulfate to the nickel-cobalt-manganese sulfate mixed salt solution, add 40ml into methylcellulose, and fully Stir, keep the temperature at 45°C, add sodium carbonate, stir until complete precipitation, a...

Embodiment 3

[0064] A kind of high nickel sodium ion cathode material, its chemical formula is NaNi 0.68 co 0.23 mn 0.09 o 2 0.037CNP-Al / 0.015NaVO 3 .

[0065] The preparation method of the above-mentioned high-nickel sodium ion positive electrode material comprises the following steps:

[0066] (1) Preparation of nickel-cobalt-manganese materials: the ternary positive electrode material recovered from waste ternary lithium batteries is subjected to acid leaching, aluminum removal, copper removal, and extraction to obtain nickel-cobalt-manganese sulfate mixed salt solution, and nickel-cobalt-manganese sulfate mixed salt solution is determined Medium nickel-cobalt-manganese molar ratio (0.965:0.12:0.11), take 500mL in a beaker, add 0.143M cobalt sulfate, 0.018M manganese sulfate to the nickel-cobalt-manganese sulfate mixed salt solution, add 50mL acrylic acid, stir well, 45℃ Keep the temperature constant, add ammonium carbonate, stir until complete precipitation, and let stand for 3 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com