Electrode material of reversible solid oxide battery and composite material, preparation method and application thereof

A solid oxide and electrode material technology, applied in battery electrodes, fuel cells, circuits, etc., can solve the problems of short life and high battery cost, and achieve the effect of improving electrical conductivity, good catalytic activity, and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

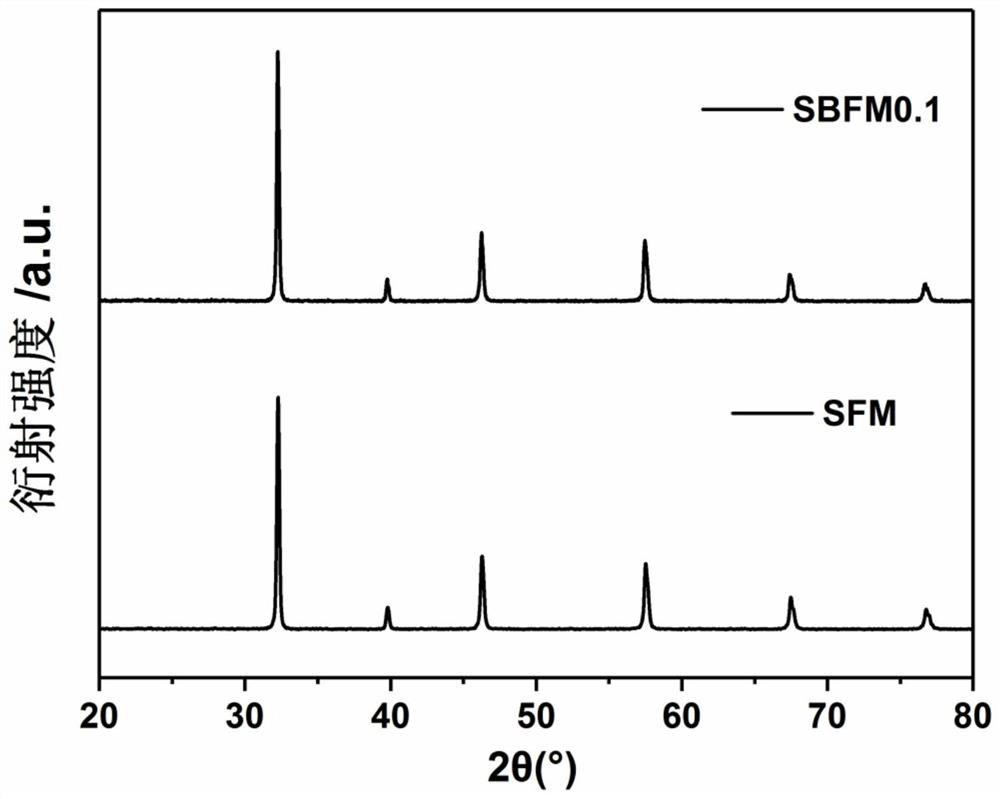

[0028] A new type of reversible solid oxide battery electrode material, the specific molecular formula is Sr 1.9 Bi 0.1 Fe 1.5 Mo 0.5 o 6-δ .

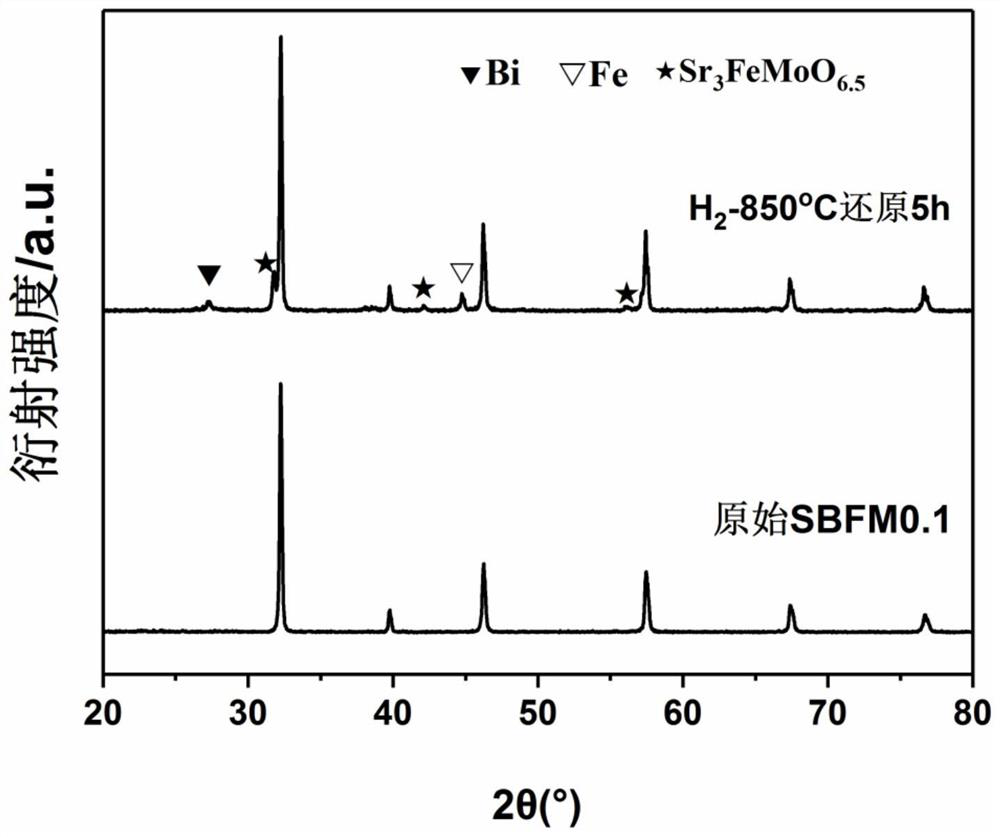

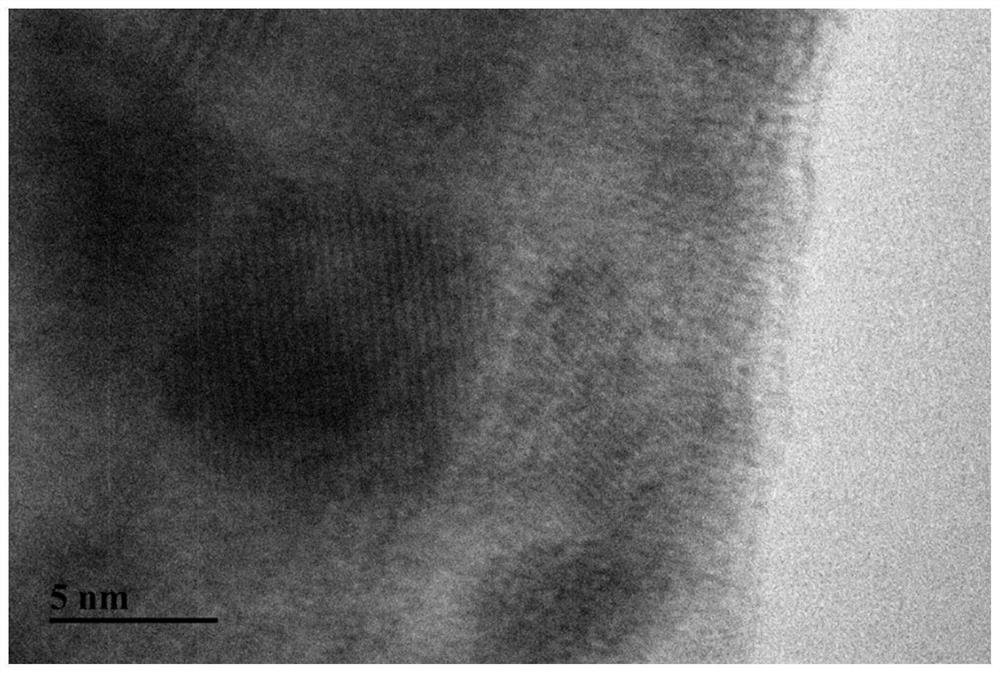

[0029] The preparation method of the reversible solid oxide battery electrode material comprises: taking 5.6098g of strontium carbonate, 0.4659g of bismuth trioxide, 2.3953g of ferric oxide, and 1.4396g of molybdenum trioxide, adding an appropriate amount of ethanol for stirring treatment to obtain a solid-liquid mixture; The solid-liquid mixture was placed in a ball mill, and ball milled at a speed of 350 rpm for 24 hours, and the ball-milled powder was dried in a drying oven at 80°C. Finally, it was calcined at 1200 °C for 12 h in air atmosphere to obtain Sr with perovskite phase structure. 1.9 Bi 0.1 Fe 1.5 Mo 0.5 o 6-δ electrode material. The prepared electrode material was heated in 5% H 2 / After reduction at 850 °C for 5 h in Ar atmosphere, Sr with perovskite support structure was obtained 3 FeMoO 6.5 -BiFe@Sr 1.9 ...

Embodiment 2

[0031] A new type of reversible solid oxide battery electrode material, the specific molecular formula is Sr 1.92 Bi 0.08 Fe 1.5 Mo 0.5 o 6-δ .

[0032] The preparation method of the reversible solid oxide battery electrode material comprises: taking 5.6689g of strontium carbonate, 0.3728g of bismuth trioxide, 2.3953g of ferric oxide, and 1.4396g of molybdenum trioxide, adding an appropriate amount of ethanol for stirring treatment to obtain a solid-liquid mixture; The solid-liquid mixture was placed in a ball mill, ball milled at a speed of 450 rpm for 20 hours, and the ball-milled powder was dried in a drying oven at 80°C. Finally, it was calcined at 1150 °C for 14 h in the air atmosphere to obtain Sr with perovskite phase structure. 1.92 Bi 0.08 Fe 1.5 Mo 0.5 o 6-δ electrode material. The prepared electrode material was heated in 5% H 2 After reduction at 900 °C for 4 h in Ar atmosphere, Sr with perovskite support structure was obtained 3 FeMoO 6.5-BiFe@Sr 1.9...

Embodiment 3

[0034] A new type of reversible solid oxide battery electrode material, the specific molecular formula is Sr 1.95 Bi 0.05 Fe 1.5 Mo 0.5 o 6-δ .

[0035] The preparation method of the reversible solid oxide battery electrode material comprises: taking 5.7575g of strontium carbonate, 0.2329g of bismuth trioxide, 2.3953g of ferric oxide, 1.4396g of molybdenum trioxide, adding an appropriate amount of ethanol for stirring treatment, and obtaining a solid-liquid mixture; The solid-liquid mixture was placed in a ball mill and ball-milled at a speed of 500 rpm for 12 hours, and the ball-milled powder was dried in a drying oven at 80°C. Finally, it was calcined at 1100 °C for 15 h in air atmosphere to obtain Sr with perovskite phase structure. 1.95 Bi 0.05 Fe 1.5 Mo 0.5 o 6-δ electrode material. The prepared electrode material was heated in 5% H 2 After reduction at 800 °C for 6 h in Ar atmosphere, Sr with a perovskite support structure was obtained. 3 FeMoO 6.5 -BiFe@Sr ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com