Method for preparing 1, 4-butanediol through hydrogenation of 1, 4-butynediol

A technology of butynediol and butanediol, which is applied in the field of 1,4-butanediol production, can solve problems such as increasing system energy consumption, and achieve the effects of size reduction, investment reduction, and energy consumption reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

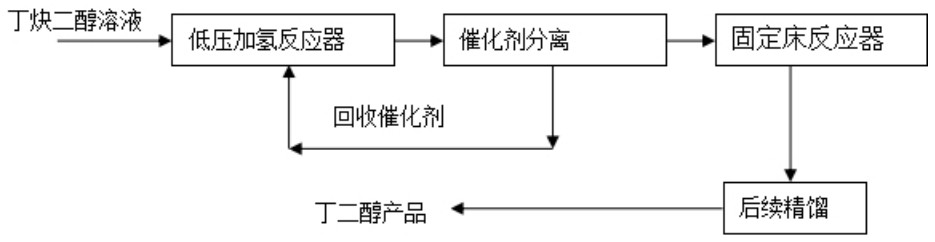

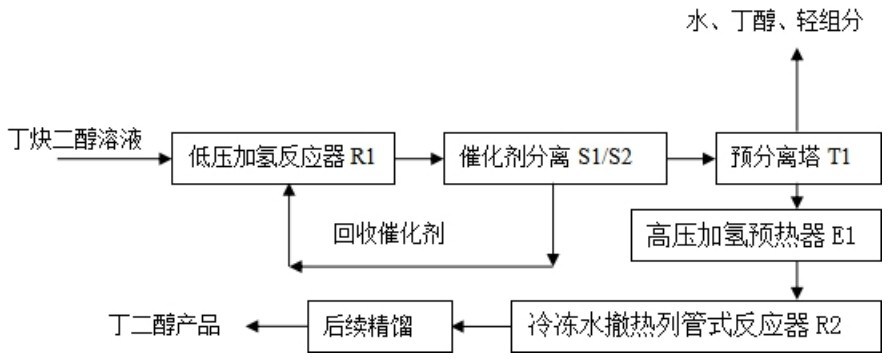

Image

Examples

Embodiment 1

[0037] In this example, the composition of the Raney nickel-aluminum-X catalyst used in the low-pressure reactor R1: the mass ratio of nickel to aluminum is 0.5:1, and the amount of X added is 1wt% of the total mass of nickel and aluminum, wherein X is Mg . The preparation process is as follows: Weigh 250kg of Ni block, 500kg of Al block and 7.5kg of Mg and place them in a medium-to-large furnace, turn on the current, and after Ni, Al and Mg are melted, heat-preserve and smelt at 900°C for 60 minutes, then pour into Cool in water; grind the catalyst obtained after cooling to 200 mesh powder; weigh appropriate amount of catalyst powder in batches and add to NaOH solution with a mass concentration of 25% to mix evenly, then control the temperature at 60°C for 30 minutes, and react After finishing, wash 3 times with distilled water, then wash with absolute ethanol until neutral.

[0038] The composition of the catalyst loaded in the chilled water deheating tubular reactor R2 is ...

Embodiment 2

[0048] In this example, the composition of the Raney nickel-aluminum-X catalyst used in the low-pressure reactor R1: the mass ratio of nickel and aluminum is 0.6:1, and the amount of X added is 1wt% of the total mass of nickel and aluminum, wherein X is Mg . The preparation process is as follows: Weigh 300kg of Ni block, 500kg of Al block and 8kg of Mg and place them in a medium-to-large melting furnace, turn on the current, and after Ni, Al and Mg are melted, keep smelting at 900°C for 60 minutes, then pour into water Cooling; the catalyst obtained after cooling was ground to 200 mesh powder; weighed an appropriate amount of catalyst powder in batches and added to the NaOH solution with a mass concentration of 25% to mix evenly, then controlled the temperature at 60°C for 30 minutes, and the reaction was completed Afterwards, wash with distilled water 3 times, and then wash with absolute ethanol until neutral.

[0049] The composition of the catalyst loaded in the chilled wa...

Embodiment 3

[0055]In this example, the composition of the Raney nickel-aluminum-X catalyst used in the low-pressure reactor R1: the mass ratio of nickel and aluminum is 0.7:1, and the amount of X added is 1wt% of the total mass of nickel and aluminum, wherein X is Mg . The production process is as follows: Weigh 350kg of Ni block, 500kg of Al block and 8.5kg of Mg and place them in a medium-to-large furnace, turn on the current, and after Ni, Al and Mg are melted, heat-preserve and smelt at 900°C for 60 minutes, then pour into Cool in water; grind the catalyst obtained after cooling to 200 mesh powder; weigh appropriate amount of catalyst powder in batches and add to NaOH solution with a mass concentration of 25% to mix evenly, then control the temperature at 60°C for 30 minutes, and react After finishing, wash 3 times with distilled water, then wash with absolute ethanol until neutral;

[0056] The composition of the catalyst loaded in the chilled water deheating tubular reactor R2 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com