Composite material for degrading bisphenol A as well as preparation method and application of composite material

A composite material and bisphenol technology, applied in the fields of nanomaterials and water pollution prevention and control, can solve problems such as complicated operation, high cost, and secondary pollution, and achieve the effects of simple preparation, expanded application range, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

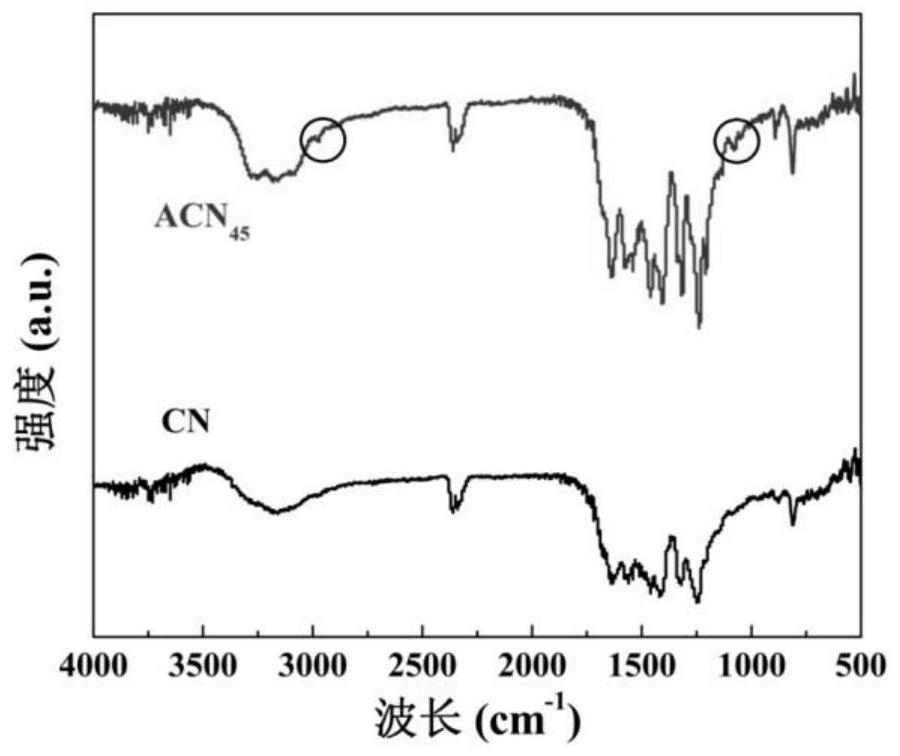

[0041] Embodiment 1: the preparation of carrier material CN and ACN

[0042] (1) Preparation of graphitic carbon nitride CN

[0043]CN was prepared by thermal polycondensation of urea: dry urea was ground into powder, and then placed in a muffle furnace at 550 °C for 4 h, with a heating rate of 2.5 °C / min. After natural cooling to room temperature, the yellow sample was acid-washed overnight in nitric acid solution (pH=1), then washed with deionized water until neutral, then centrifuged at 6000 r / min for 3-5 min, and dried at 60 °C for 24 h. CN available.

[0044] (2) Preparation of ACN

[0045] ACN is prepared by thermal polycondensation of a mixture of urea and 4-aminopyridine: 20 g of dry urea and 0.09 g of 4-aminopyridine are mixed and ground into powder, and the two are fully mixed, and then the mixture is placed in a muffle at 550 °C Keep in the furnace for 4 h with a heating rate of 2.5 °C / min. After naturally cooling to room temperature, the light yellow sample was...

Embodiment 2

[0048] Embodiment 2: the preparation of HRP / ACN immobilized enzyme

[0049] 0.3g of ACN was dispersed in 4mL of PBS, and dispersed evenly by ultrasonic. Then 0.7 mL of HRP solution with a concentration of 1 mg / mL was added dropwise to the above mixture, and the reaction was stirred at room temperature for 20 min. Finally, it was separated by centrifugation at 8000 r / min for 5 min, and the centrifuged sample was placed in a freeze dryer at -80 °C for 24 h to obtain the HRP / ACN composite material.

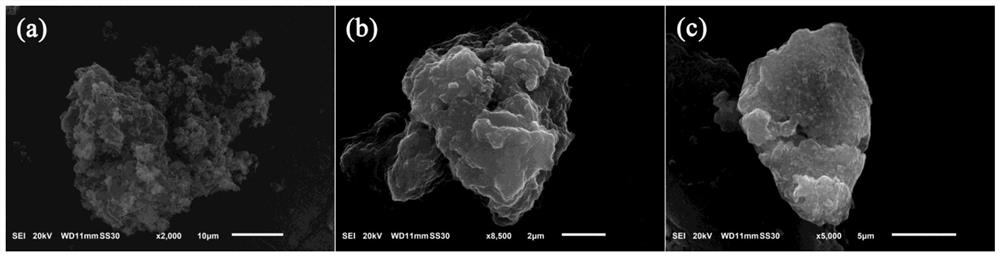

[0050] figure 2 In Figures a-c, CN (a), ACN 45 (b) and HRP / ACN 45 The SEM image of (c), the three materials under the SEM image all show a bulk structure, but the surface of ACN is relatively smoother than that of CN after doping with 4-aminopyridine, figure 2 In c, after ACN is loaded with HRP, its surface is relatively "smooth", with some changes but still not obvious.

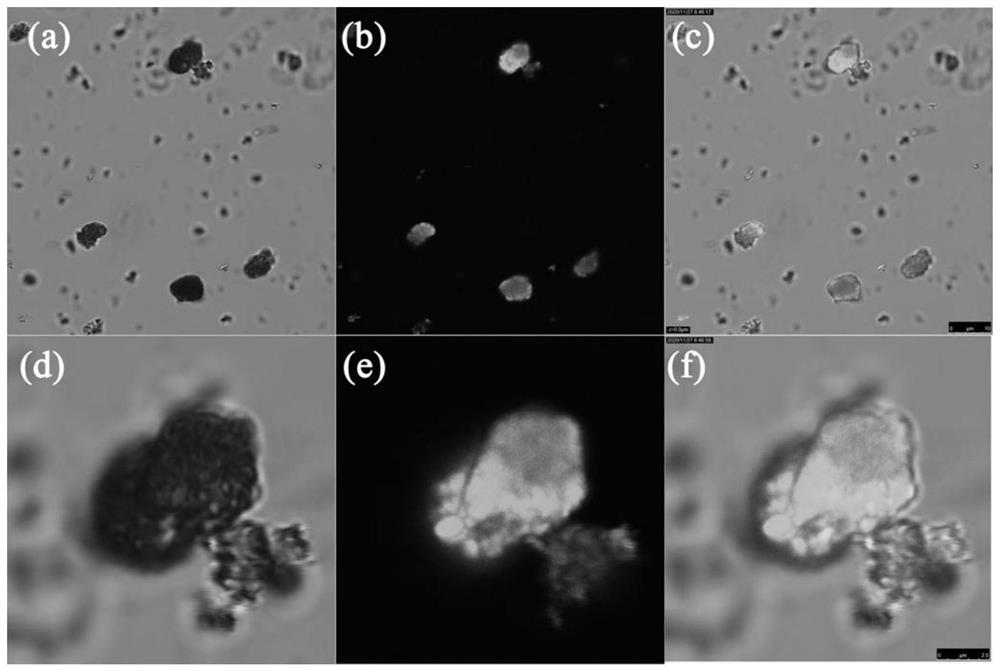

[0051] Observation of changes in bright field and fluorescence field by laser confocal microscopy (LSC...

Embodiment 3

[0056] Embodiment 3: HRP / ACN immobilized enzyme preparation condition optimization

[0057] (1) The effect of ACN content on the solid loading capacity of HRP / ACN

[0058] Add different amounts of ACN (0.1–0.9 mg) to 4 mL of PBS buffer, and sonicate to form a suspension. Subsequently, 1 mL of HRP solution with a concentration of 1 mg / mL was added dropwise to the above mixture, and PBS buffer solution was added to ensure that the volume was the same as 5 mL. Stir the reaction at room temperature for 20 min, and centrifuge at 8000 r / min for 5 min to separate, test the content of HRP before and after immobilization, and obtain the effect of the amount of carrier material on the immobilization capacity of HRP.

[0059] Figure 5 Shown in a is the effect of different amounts of carrier materials on the immobilized amount of HRP. The results showed that when the amount of carrier material was 0.3 mg, the immobilized amount of HRP reached 708.67 mg / g, and then increased the carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fixed capacity | aaaaa | aaaaa |

| Michaelis constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com