Composite copper oxide catalyst, preparation method and application

A catalyst, copper oxide technology, applied in catalyst activation/preparation, Raney-type catalysts, physical/chemical process catalysts, etc., can solve problems such as being unsuitable for large-scale industrial applications, unable to meet process requirements, and serious environmental pollution. Achieve the effect of easy recovery, high copper loading and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] (1) the powdery phenolic resin of 200g is fully mixed with the curing agent hexamethylenetetramine of 24g with a high-speed mixer, obtains the compound of 224g;

[0085] (2) The above-mentioned mixture of 100g is fully mixed with the copper powder of 20g melamine, the copper powder of 545g, the aluminum powder of 468g and the zinc powder of 100g with a high-speed mixer; Molded on the tablet press, formed into a sheet with a thickness of 2 mm; the temperature of the tablet press was raised to 150 ° C, and the formed sheet was put into the mold again and cured for 10 minutes under a pressure of 5 MPa on the tablet press; the cured 2 mm The thick sheet is cut into small particles to obtain the catalyst precursor;

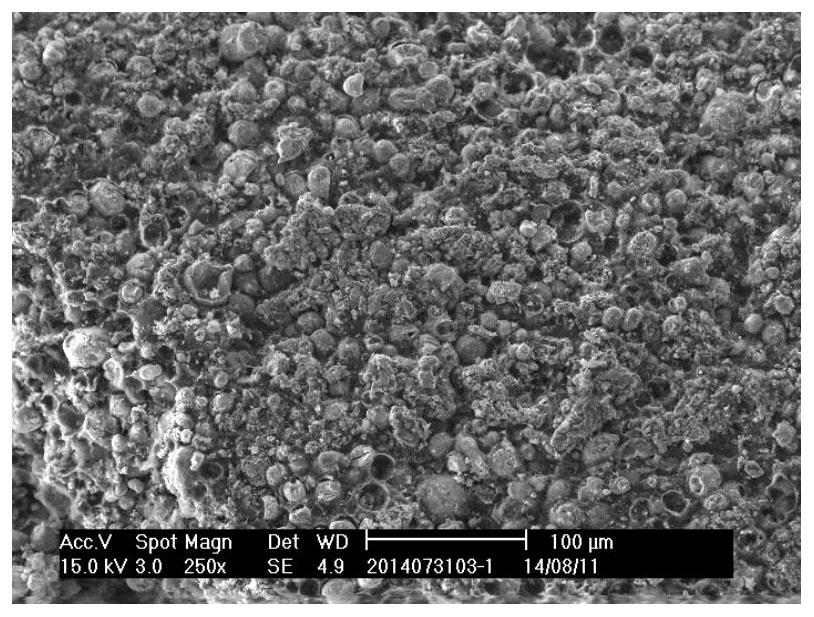

[0086] (3) Measure 200 mL of the small particles obtained in step (2), and carbonize them in a tubular high-temperature electric furnace at a heating rate of 10°C / min at a furnace temperature of 650°C for 3 hours under nitrogen protection at a flow rate of 200mL...

Embodiment 2

[0089] (1) the powdery phenolic resin of 200g is fully mixed with the curing agent hexamethylenetetramine of 24g with a high-speed mixer, obtains the compound of 224g;

[0090] (2) Fully mix 100g of the above compound with 10g of melamine formaldehyde resin, 545g of copper powder, 468g of aluminum powder and 50g of zinc powder with a high-speed mixer; raise the temperature of the tablet press to 100°C, and put the above materials into the mold Molding is performed on a tablet press to form a sheet with a thickness of 2mm; the temperature of the tablet press is raised to 140°C, and the formed sheet is put into the mold again and cured for 12min under a pressure of 5MPa on the tablet press; the cured The 2mm thick sheet is cut into small particles to obtain the catalyst precursor;

[0091] (3) Measure 200 mL of the small particles obtained in step (2), and carbonize them in a tubular high-temperature electric furnace at a heating rate of 10°C / min at a furnace temperature of 650°...

Embodiment 3

[0094](1) the powdery phenolic resin of 200g is fully mixed with the curing agent hexamethylenetetramine of 24g with a high-speed mixer, obtains the compound of 224g;

[0095] (2) Fully mix 100g of the above compound with 5g of melamine formaldehyde resin, 545g of copper powder, 468g of aluminum powder and 200g of zinc powder with a high-speed mixer; raise the temperature of the tablet press to 110°C, and put the above materials into the mold Molding is carried out on the tablet press to form a sheet with a thickness of 2 mm; the temperature of the tablet press is raised to 120 ° C, and the formed sheet is put into the mold again and cured for 20 minutes under a pressure of 4 MPa on the tablet press; the cured The 2mm thick sheet is cut into small particles to obtain the catalyst precursor;

[0096] (3) Measure 200 mL of the small particles obtained in step (2), and carbonize them in a tubular high-temperature electric furnace at a heating rate of 10°C / min at a furnace tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com